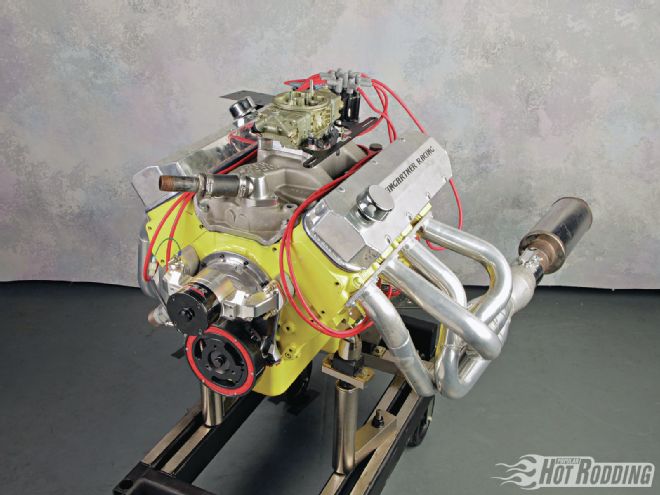

When it comes to big-block Chevrolet performance engines, they come in all categories. With virtually boundless components from the aftermarket, the high-end of the spectrum is nothing short of exotic. Eric Weingartner took an alternate approach, looking to make the most of what can be considered everyday-style parts in a budget 496 combination that can swap blows with the big boys. The engine was built for our annual engine-building competition, the AMSOIL Engine Masters Challenge, an event that had this engine competing with the best efforts of some of the most talented engine builders in the business. Considering the restrained component selection of this engine combination, Weingartner’s solid mid-pack finish was proof enough of the engine’s worth.

Build It

Want to build big power on a budget from a big-block Chevrolet? Take a factory four-bolt block and stuff it with a Scat 4.25-inch crank to make 496 cubes, tie it in with ARP studs, and then finish it off with a set of forged Probe pistons hanging from Scat forged I-beam rods.

Want to build big power on a budget from a big-block Chevrolet? Take a factory four-bolt block and stuff it with a Scat 4.25-inch crank to make 496 cubes, tie it in with ARP studs, and then finish it off with a set of forged Probe pistons hanging from Scat forged I-beam rods.

Starting with a factory four-bolt main block, Weingartner began with a modest but capable foundation. Sure, an aftermarket block would have been a step up, but for the required powerband, the OEM GM block was a far more economical choice. As Weingartner tells us, “I would have liked an aftermarket block with a 4.500-inch bore, and run a little less stroke, but that doesn’t work as well in the competition because you need that torque down low.” The block was upgraded with ARP main cap fasteners, and otherwise left pretty much as Chevrolet built it. A key to making the used block work, however, was in the detail and accuracy of the machining. Here, Weingartner gives plenty of credit to his machine shop, Dunsworth Machine. They did all the work on the block, with a full block prep including clearancing for a stroker crank of up to 4.375 inches. Dunsworth also provided the dyno services for the performance tuning and development of the finished engine.

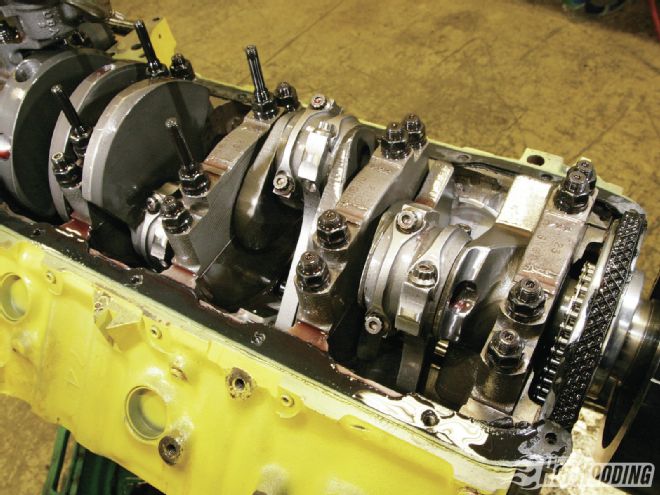

While the block began as a stock production piece, the parts that filled it are strictly aftermarket. Here, Weingartner looked to gain maximum value by selecting parts that would do the job reliably over the long haul, while refraining from stepping into the more high-dollar equipment. Starting with the crank, Weingartner went with a Scat 4340 forged steel piece, with a stroke length of 4.250 inches. This is a popular off-the-shelf piece, making it an excellent value, especially when you consider that it’s practically bulletproof. That’s one of the keys to Weingartner’s budget approach—using readily available and proven parts combinations. Complementing the crank is a set of Scat 4340 I-beam rods measuring 6.385 inches, with ARP 2000 capscrews. Again, these are commonly available parts offering real value in terms of service durability versus cost.

Who says a bulletproof bottom end has to cost a fortune? This big-block uses readily available parts such as Scat 6.385-inch I-beam rods and Probe forged pistons—affordable parts that are made to go the distance.

Who says a bulletproof bottom end has to cost a fortune? This big-block uses readily available parts such as Scat 6.385-inch I-beam rods and Probe forged pistons—affordable parts that are made to go the distance.

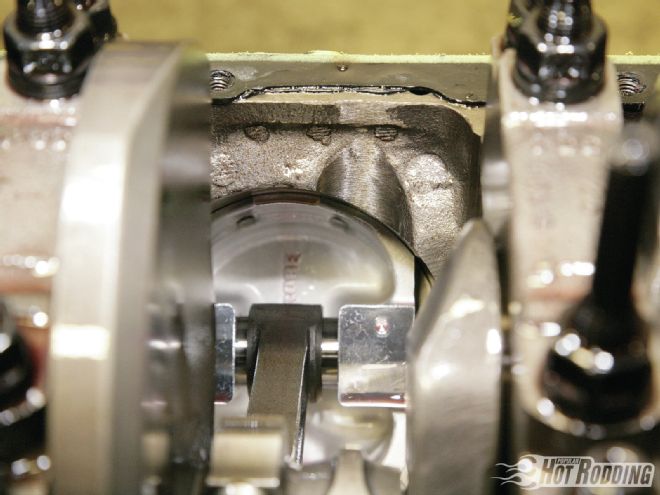

Filling the bores are a set of Probe small-dome forged pistons, with conventional 1/16-1/16-3/16 ring grooves. Where Weingartner decided to go with a more esoteric setup was the rings. The bores are sealed with a custom low-tension set of Total Seal gapless top rings. Weingartner says, “I was afraid I might detonate and get too hot, butting the rings. With the gapless, I was able to open the ring gaps for more insurance, and still get the seal. With the low tension, they weren’t dragging much. I remember when I was turning the engine over with all the pistons in, it was only about 12 lb-ft to turn the engine over.”

Although this combination carries a crank with a 4.25-inch throw, Weingartner had the block clearanced for a 4.375-inch stroke. This allows the same block to be used at even greater displacement.

Although this combination carries a crank with a 4.25-inch throw, Weingartner had the block clearanced for a 4.375-inch stroke. This allows the same block to be used at even greater displacement.

Power Parts

Weingartner’s specialty is in cylinder head porting, and here he had a chance to put that expertise to work. Sure, the easy path to high airflow would have been a set of expensive CNC-ported aluminum race heads. Weingartner, however, started with a modest set of RHS cast-iron 320cc heads. Weingartner explains, “It took a lot of trial and error, and when I first got done with the prototype, it was perfect. The RHS heads have a big and long short-side turn in the port, which really helps the low-lift flow. They are really good down low, and they are not that big. We got it digitized and ran the heads CNC ported. I had to angle mill the heads .112 inch to get the compression ratio up, but the angle milling hurt the flow. I spent lots more time grinding to get it back where it was, and then had to use epoxy to fill it to get the runner volume back down.”

The heads were finished off with REV stainless steel valves, measuring 2.250-inch intake and 1.880-inch exhaust. In terms of valve selection, Weingartner says, “I ran a 2.250-inch intake valve because I could never get the flow from a 2.300-inch valve on the 4.310-inch bore. The 2.250 was always better. I use a tulip exhaust valve—the theory being that you do not have as much of a cross-sectional area change off the seat as with a nailhead valve. It keeps the air flowing better and I know it helps the low-lift flow on the exhaust.”

For the AMSOIL Engine Masters Challenge, the rules required a two-plane intake manifold. Weingartner selected the Brodix intake because it was the largest capacity two-plane he could find for the rectangular-port heads.

For the AMSOIL Engine Masters Challenge, the rules required a two-plane intake manifold. Weingartner selected the Brodix intake because it was the largest capacity two-plane he could find for the rectangular-port heads.

Weingartner expanded by discussing the intake manifold: “The intake manifold was a compromise, since by the rules we had to run a dual-plane. I used the Brodix, since it was the biggest one I could find for a rectangular port. The heads flowed 400 cfm, but as soon as I bolted the intake to it, the flow dropped to 352. I would have liked to have done more work to the intake manifold, and if I would have read the rules more closely on what was allowed, I would have ground more on it. I did some more work after the competition, and with the intake bolted to the heads, they flowed 362 cfm. That was a mistake. I should have done more to the intake.” For the carb, Weingartner ran an 830 Holley.

The camshaft selection for this combination began with a custom stick from Mike Jones Camshafts, but this long-duration cam was just not going to clear as far as piston-to-valve clearance. A smaller COMP cam was substituted, and Weingartner was skeptical, expecting it to nose over too early. Weingartner tells us, “The COMP cam proved to be really good. I was pretty happy with the cam, because I didn’t think with that duration, on this big of an engine, that it would hold on at the higher rpm as good as it did, but it did.” The cam was ground on a lobe separation of 106, and Weingartner found it made the best power installed at 4 degrees advanced. The valvetrain was finished off with a set of Scorpion rocker arms, COMP pushrods and keepers, and Herbert limited-travel lifters, springs, and retainers.

Weingartner’s specialty is cylinder head modification. Once ported to perfection, Weingartner made over 400 cfm from these RHS iron castings. That is serious flow, especially when considering the modest port volume.

Weingartner’s specialty is cylinder head modification. Once ported to perfection, Weingartner made over 400 cfm from these RHS iron castings. That is serious flow, especially when considering the modest port volume.

Finishing It Off

There are always the final details on any engine build, and here Weingartner again looked to maximize value. The lubrication system was provided for by a stock replacement Melling oil pump, which Weingartner extensively ported for improved flow. To complement the pump, the engine was fitted with a Hamburger oil pan, which comes with an integral windage screen and scraper. As a precaution, Weingartner sealed the lifter valley with screens epoxied into the oil drainbacks to prevent any debris from entering the mechanicals below. The headers are Doug’s 2.25-inch units, featuring a set of added Edelbrock merge collectors. To light the fire, Weingartner used a PerTronix I3. As Weingartner related, “I love that thing. It’s far less complicated; it only has two wires, and it hooks right up. That PerTronix distributor is an angel; I use it in almost everything I have. I’m a huge fan of PerTronix, it doesn’t cut out, and the timing seems stable … they make good products.” MSD wires finish the ignition.

Weingartner discloses that the intake manifold received heavy porting in the runners, along with a fill of epoxy in the floor to match the cylinder heads, but the manifold definitely crimped the peak cylinder head airflow. More work in the plenum area was required to bump the flow of the intake/head combination.

Weingartner discloses that the intake manifold received heavy porting in the runners, along with a fill of epoxy in the floor to match the cylinder heads, but the manifold definitely crimped the peak cylinder head airflow. More work in the plenum area was required to bump the flow of the intake/head combination.

Overall, Weingartner put together an effective bread-and-butter combination—the familiar 496 Chevy big-block. Right down to the bore, stroke, and rod length, this engine used conventional parts that are readily available from the aftermarket, and priced right too. With 660 hp on tap through a single four-barrel carb and running a hydraulic cam on pump gas, that’s power in a simple street package. Simple, cost-effective engines that work are a Weingartner trademark—and who can argue with that?

Bore: 4.310 inches

Stroke: 4.250 inches

Displacement: 496 ci

Block: factory GM four-bolt with ARP main studs

Compression ratio: 11.3

Engine fasteners: ARP

Crankshaft: Scat 4340

Camshaft: COMP Cams custom hydraulic roller

Timing chain: Cloyes Hex-A-Just

Lifters: Doug Herbert limited travel hydraulic roller

Pushrods: COMP Cams ⅜-inch diameter

Spring: Doug Herbert Alpha Series

Valvespring installed height: 2.050 inches

Spring load: 220 pounds seat/590 pounds over the nose

Retainers: Doug Herbert titanium

Keepers: COMP Cams 4130 10-degree

Intake duration: 246 degrees at .050

Intake valve lift: .647-inch gross

Exhaust duration: 248 degrees at .050

Exhaust valve lift: .634 inch gross

Rocker ratio: 1.85:1 intake, 1.75:1 exhaust

Lobe separation: 106 degrees

Installed centerline: 102 degrees

Top ring: Total Seal, gapless 1/16 inch

Top ring gap: .028 inch

Second ring: Total Seal Classic (not gapless) 1/16

Second ring gap: .032 inch

Oil ring: Total Seal 3/16-inch low-tension

Pistons: Probe forged

Main bolts: ARP studs

Rods: Scat 4340 I-beam, 6.385-inch long with ARP 2000 capscrews

Main journal: Chevy OE

Bearings: Clevite H-series

Main bearing clearance: .0030

Rod journals: Chevy OE

Rod bearing clearance: .0026

Cylinder heads: RHS cast-iron 320cc, CNC ported by Weingartner Racing

Peak intake flow: 405 cfm

Peak exhaust flow: 305 cfm

Intake valves: REV stainless, 2.250 inches

Exhaust valves: REV stainless, 1.880 inches

Cylinder head gaskets: Fel-Pro 1037, .039-inch compressed thickness

Piston quench clearance: .039

Intake manifold: Brodix rectangular-port dual-plane

Carburetor: Holley 830 cfm

Headers: Doug’s Headers, 2.250-inch primaries

Ignition: PerTronix I3

Distributor: PerTronix I3

Spark plug wires: MSD

Damper: Professional Products

Water pump: CVR

Oil pan: Hamburger

Oil pump: Melling standard volume

Machine work: Dunsworth Machine Shop, Enid, OK

On The Dyno

496ci Big-Block Chevy 91-Octane Fuel

RPM TQ HP 2,500 529 252 2,600 542 268 2,700 549 282 2,800 556 296 2,900 566 313 3,000 579 331 3,100 588 347 3,200 590 360 3,300 586 368 3,400 577 374 3,500 568 379 3,600 562 386 3,700 568 400 3,800 581 420 3,900 593 441 4,000 599 456 4,100 602 470 4,200 606 484 4,300 610 499 4,400 614 514 4,500 618 530 4,600 621 544 4,700 622 557 4,800 621 568 4,900 622 580 5,000 621 591 5,100 619 601 5,200 618 612 5,300 615 621 5,400 612 629 5,500 607 636 5,600 600 640 5,700 594 645 5,800 587 648 5,900 579 650 6,000 572 654 6,100 567 659 6,200 559 660 6,300 545 654 6,400 529 644 6,500 516 638