Fifty years ago, the Chevrolet W-series 348/409 blazed a legendary trail across America's racetracks. While Chevy's early big-block has always retained a faithful following among resto guys and nostalgia racers, until recently the lack of modern piston, ring, cam, valvetrain, and cylinder head technology limited the engine's potential. The introduction of Edelbrock aluminum heads a year ago began a rekindling of interest in the historical engine, and it's now possible to bring it into the 21st century with modern high-tech ingredients, including Scat stroker cranks and rods, CP flyweight pistons with thin rings, Comp quick-acting mechanical roller cams, and T&D shaft-mount rocker systems. The only limiting factor is the scarcity of blocks, with rebuildable 409 castings costing a pretty penny. However, the smaller 348 blocks can still be found, and hopefully by the time you read this, World Castings will have released its long-rumored Merlin aluminum 409 block with four-bolt mains and the capability to build 509ci engines.

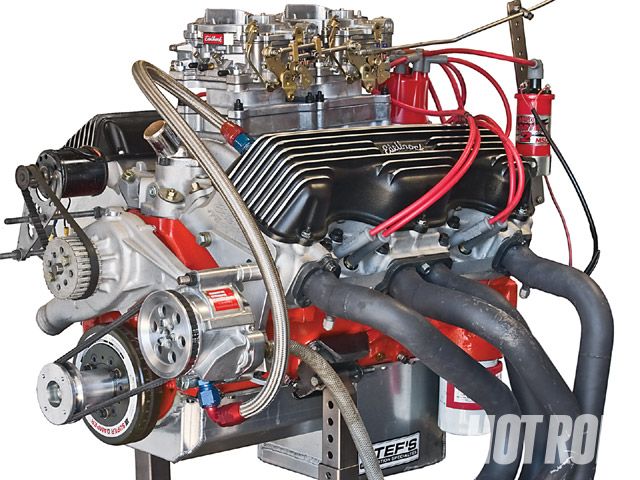

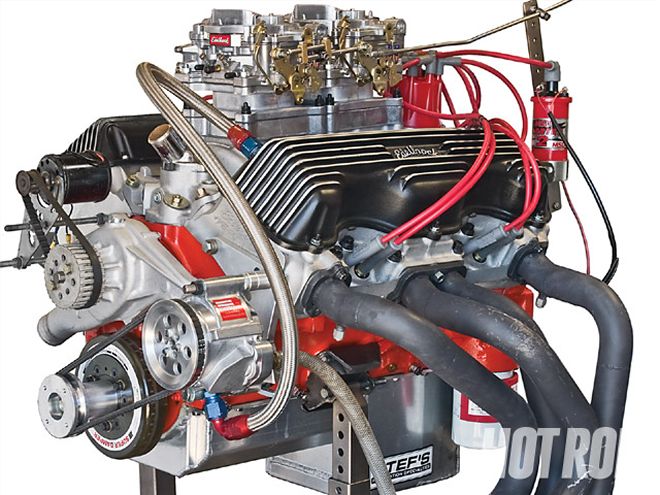

In an age of cookie-cutter, me-too small-blocks, the Chevy 348/409 stands apart with its distinctive scalloped valve covers. This engine may be more than 50 years old, but with modern heads, cam, and rotating assembly technology, it's capable of more than 650 hp and nearly 535 lb-ft on 91-octane gas.

In an age of cookie-cutter, me-too small-blocks, the Chevy 348/409 stands apart with its distinctive scalloped valve covers. This engine may be more than 50 years old, but with modern heads, cam, and rotating assembly technology, it's capable of more than 650 hp and nearly 535 lb-ft on 91-octane gas.

In the meantime, Joe Sherman decided to revisit 348/409 technology using modern parts. Sherman is well known to HOT ROD for making big power numbers per dollars invested and even used to race the W-series motors back in the day. So that HOT ROD's readers could actually replicate this build in the real world, Sherman started with a more available 348, boring it 0.045 over and installing a Scat 4.00-inch stroker crank to build a 437 that makes 650 hp on pump gas. That's about 150 hp more than a good-running, old-school, full-race 409 used to make back in its days of legend. Read on to find out what it takes to reanimate your own W-series mill.

Block And Rotating Assembly

Why build a 348? "Most 409s have been rebuilt already and are hoarded by collectors," Sherman says. "A 409 core typically costs $4,500 to $5,000; you can get a 348 for only $1,000 to $2,000." The 348 and 409 blocks are easy to tell apart: A 348 block has the oil dipstick on the driver side; a 409 block's is on the passenger side. For this build, Sherman found a pristine, never-overbored 348 block, but after the build was under way, it was discovered that early-production '58 castings have some undesirable design features.

Scat supplied a neutral-balanced, 4.00-inch-stroke, forged 4340-steel crank. A 348/409 has the same bore spacing and 2.20-inch rod journals as a modern big-block Chevy. The front crank snout and timing cover seal are the same as a small-block. Only the 2.5-inch main bearing diameter is unique.

Scat supplied a neutral-balanced, 4.00-inch-stroke, forged 4340-steel crank. A 348/409 has the same bore spacing and 2.20-inch rod journals as a modern big-block Chevy. The front crank snout and timing cover seal are the same as a small-block. Only the 2.5-inch main bearing diameter is unique.

Some '58-only blocks- including Sherman's 348 casting No. 3732811 as well as No. 3751872-lack spark plug cooling hole provisions found on later blocks and use a rope rear main seal (no other two-piece rubber seal fits). Later 348 and all 409 blocks use a standard Mark IV big-block Chevy two-piece rubber rear main seal. Sherman's early block was also drilled with a weird three-hole starter mounting pattern.

Many 348s can be safely bored up to 0.125 inch oversize after sonic-checking (from the stock 4.125 bore all the way to 4.25), but that's still smaller than a stock 409's 4.31-inch bore size. Being conservative, Ultra Precision Machine bored and honed Sherman's block 0.045 inch over to 4.170 inches. With the 0.045 overbore and 4-inch Scat stroker crank, displacement came in at 437 ci. Ultra also cleaned, Magnafluxed, and decked the block, align-honed the mains, balanced the rotating the assembly, and touched up the intake valve seat radius on Edelbrock's heads.

With its heavy stock rotating mass, a 348/409 doesn't traditionally like to wind much past 6,200 rpm. Sherman's setup shaves about 275 grams and can rev more than 7,000, thanks to a long rod that allows a shorter piston, CP's unorthodox box-section-like piston reinforcement that cuts weight while adding strength, and shorter (and lighter) pins.

With its heavy stock rotating mass, a 348/409 doesn't traditionally like to wind much past 6,200 rpm. Sherman's setup shaves about 275 grams and can rev more than 7,000, thanks to a long rod that allows a shorter piston, CP's unorthodox box-section-like piston reinforcement that cuts weight while adding strength, and shorter (and lighter) pins.

Sherman gives two reasons for the strange 0.045 overbore: First, the CP custom pistons were ordered before Sherman actually had a block, so he couldn't be sure what shape the bores would be in. Second, for reduced drag, the trick CP pistons use a thin, ultralow-tension, 1.2mm-0.043-inch-3mm ring pack with the two compression rings back-cut for reduced radial clearance. In Sherman's experience, such ultrathin rings "are fragile, and it's really dicey to excessively file-fit them." Ordering the custom CP pistons 0.045 instead of 0.040 over kept hand-filing to a minimum with the usual 0.005 oversize file-fit ring sets intended for a 0.040-over build.

Accepting a semi-Dykes ring, the top groove has a top relief that develops more pressure behind the ring-"kind of like a gas port without the gas port," Sherman says. An accumulator groove between the top and second ring alleviates interring pressure buildup. For improved oil control, a scraper-like Napier ring fits the second compression groove.

Accepting a semi-Dykes ring, the top groove has a top relief that develops more pressure behind the ring-"kind of like a gas port without the gas port," Sherman says. An accumulator groove between the top and second ring alleviates interring pressure buildup. For improved oil control, a scraper-like Napier ring fits the second compression groove.

Sherman was able to install the pistons and thin rings by hand into the cylinder without a compressor, nixing the need for the large (and compression-ratio-reducing) installation chamfer found on many stock slant-deck 348/409 mills. Note that on a high-perf 348/409, only the piston's intake side has a valve relief. There are two different mirror-image pistons, with the intake valve notch location reversed to line up with the particular cylinder's intake valve location. Final compression ratio is 11.0:1.

Cylinder Heads

What really helps wake up a 348/409 is Edelbrock's new aluminum heads (PN 60819, complete; PN 60809, bare). As cast, the Edelbrocks can support about 575 normally aspirated horsepower. Sherman upped the ante, considerably porting the heads' intake side. His pushrod-pinch and short-side mods really paid off, upping the heads' theoretical performance potential to 677 hp, a more than 100hp improvement. The heads install on the block using ARP head bolt set PN 135-3602 and Fel-Pro PN 8007PT head gaskets included in the Fel-Pro full overhaul set PN FS8007PT-3. The same overhaul set fits all 348/409 engines. Fel-Pro doesn't offer 348/409 performance gaskets.

Edelbrock 348/409 heads maintain the stock big-port 409 locations and valve angles but use an improved port design for more performance. Stainless steel 2.19/1.72-inch valves, hardened spring cups, screw-in studs for conventional big-block Chevy stud mount rockers, thick 9/16-inch decks, and guideplates for 3/8-inch pushrods are standard.

Edelbrock 348/409 heads maintain the stock big-port 409 locations and valve angles but use an improved port design for more performance. Stainless steel 2.19/1.72-inch valves, hardened spring cups, screw-in studs for conventional big-block Chevy stud mount rockers, thick 9/16-inch decks, and guideplates for 3/8-inch pushrods are standard.

Cam And Valvetrain

A solid roller cam is needed to keep up with the ported heads and make big numbers upstairs. The custom profile is based on Comp Cam's popular HXL lobe series. HXLs are favored by many Super Stock drag racing and oval track racers, making great torque and power in a moderately sized head. Sherman says, "These profiles have relatively big lift and valve motion without beating up the valvetrain." This engine's steel billet roller has more than 0.700-inch lift and more than 260 degrees duration at 0.050. Sherman ordered it with an optional pressed-on cast-iron distributor drive gear that permits retaining the conventional iron distributor gear for long-term street durability. As delivered, Edelbrock's heads come with 120-pound springs capable of supporting up to 0.600-inch-lift flat-tappet cams. Sherman replaced them with Comp's roller cam-compatible dual springs. The cam used has 265/270 duration at 0.050, lift with 1.7:1 rockers of 0.737/0.737 inch, and an LSA of 108 degrees.

Lubrication

A Stef's aluminum oil pan and Stef's supplied big-block Chevy oil pump circulates 10W-30 oil. With the pan's sophisticated internal baffling, a separate windage tray isn't needed. If using a stock-type pan, a '65 to '74 big-block Vette windage tray (GM PN 3967854) fits. For maximum valvetrain durability, Sherman did not restrict top end oiling. A beltdriven crankcase evacuation vacuum pump is mandatory with this motor's thin compression rings and 7-pound ultralow-tension oil ring.

The engine must rotate with no bind through its full operating cycle. Pushrod hole clearance was tight. Normally T&D 409 kits use right- and left-offset intake and exhaust rockers. But this build ended up with zero-offset rockers on four of eight exhausts. Comp Hi-Tech 3/8 pushrods are used: 9.000-inch exhausts (PN 7918) and 8.700-inch intakes (PN 7907).

The engine must rotate with no bind through its full operating cycle. Pushrod hole clearance was tight. Normally T&D 409 kits use right- and left-offset intake and exhaust rockers. But this build ended up with zero-offset rockers on four of eight exhausts. Comp Hi-Tech 3/8 pushrods are used: 9.000-inch exhausts (PN 7918) and 8.700-inch intakes (PN 7907).

Like all '67-and-earlier Chevy V-8s, the 348/409 originally had a canister-style oil filter. The 409 resto specialists at Show Cars offer a conversion kit (PN 3222A) for the later, more convenient, Chevy spin-on filter (ACDelco 1218 or equivalent). This kit requires use of the original '67-and-earlier bypass valve; if you don't have one, order Show Cars PN 3222. Sherman also used a FilterMag clamp-on magnet with 600 pounds of pull force (PN RA365) to help the spin-on filter trap potentially dangerous particles. "It's cheap insurance," Sherman says.

Stef's Nostalgia Series 6-quart (with filter) oil pan (PN 1085 for 409, PN 1086 for 348) features its trademark side power kickout with a recovery tray to enhance high-rpm windage. The pan fits most classic '58 to '62 fullsize Chevys as well as many classic muscle cars.

Stef's Nostalgia Series 6-quart (with filter) oil pan (PN 1085 for 409, PN 1086 for 348) features its trademark side power kickout with a recovery tray to enhance high-rpm windage. The pan fits most classic '58 to '62 fullsize Chevys as well as many classic muscle cars.

Fuel, Spark, And Exhaust

Sherman installed Edelbrock's Performer RPM dual-quad intake, which looks like a classic period piece but incorporates modern engineering design for max performance in the 1,500- to 6,500-rpm range. He says its the best mass-market 409 intake currently available. For those who prefer a single four-barrel, Edelbrock has a new Performer RPM single-carb intake as well (PN 7158, small-port heads; PN 7159, large-port heads).

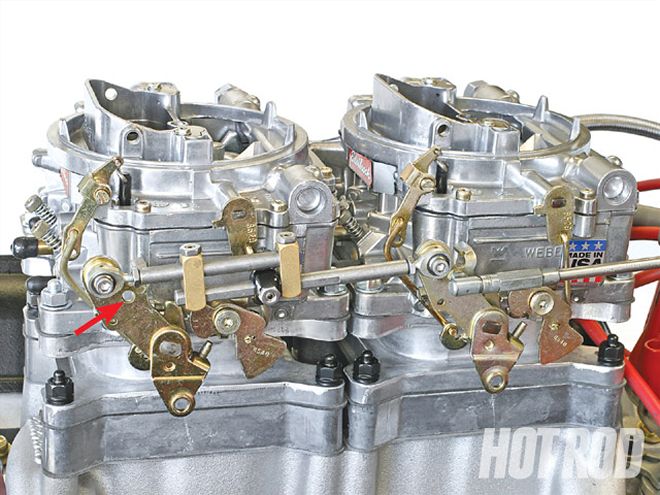

Performer 750s feed the fuel atop 3-inch open spacers. When Edelbrock's throttle linkage kit (PN 7094) is installed as shown, the linkage is 1:1; both carbs open simultaneously. With the front rod in the lower hole (arrow), the linkage is progressive; at idle and low speed, the engine runs off the rear carb only, as per original GM 409 2x4 setups.

Performer 750s feed the fuel atop 3-inch open spacers. When Edelbrock's throttle linkage kit (PN 7094) is installed as shown, the linkage is 1:1; both carbs open simultaneously. With the front rod in the lower hole (arrow), the linkage is progressive; at idle and low speed, the engine runs off the rear carb only, as per original GM 409 2x4 setups.

The dual-quad intake accepts only AFB- or AVS-type carbs. On this max-performance effort, Sherman utilized two Edelbrock Performer 750-cfm units (PN 1407) with "the richest metering rods just to be safe."

Most standard 348/409 headers have 1 7/8-inch primaries and 3 1/2-inch collectors, as per the generic dyno headers used by Sherman to run this engine on the dyno. However, the high-revving stroker could really use larger headers, such as the classic early '60s Jardine 2-inch tri-Ys.

Buildsheet

Note: All dimensions in linear inches unless otherwise stated. Engine type: Chevrolet 348/409 OHV V-8 Compression ratio: 11.0:1 Displacement: 437 ci Bore x Stroke: 4.170 × 4.000 Fuel: Chevron 91-octane unleaded Total advance: 40 degrees Max power at rpm: 650.5 hp at 6,900 rpm Max torque at rpm: 533.8 lb-ft at 5,500 rpm Estimated cost (parts and labor): $14,000

Short-Block Clearances Main bearing: 0.0025 Rod bearing: 0.0022 to 0.0027 Crank thrust: 0.008 Rod side: 0.020 Rod center to center: 6.385 Piston to wall: 0.005 Piston compression distance: 1.200 Piston deck height: -0.005 (above deck) Top ring endgap: 0.017 to 0.019 Second ring endgap: 0.014 to 0.016 Oil ring endgap: 0.022 Piston to valve: 0.075/0.085

Camshaft Type: Custom Comp Cams solid roller Grind No.: 409CH 3409S /4265S R108 Lobe lift: 0.434/0.434 Rocker arm ratio: 1.70/1.70 Valve lift (zero lash): 0.737/0.737 Duration at 0.020: 298/303 degrees Duration at 0.050: 265/270 degrees Lobe separation: 108 degrees Installed centerline: 106/110 degrees Valve lash (cold): 0.012/0.012

Cylinder Heads Type: Edelbrock aluminum, PN 60819 Valves: 2.200/1.720 Runner volume (as cast): 220/115 cc Chamber volume: 7 cc Head gasket volume: 12.2 cc Flow at 0.700 lift (ported): 329/226 cfm Spring pressure closed: 270 pounds at 2.000 Spring pressure open: 670 pounds at 1.300

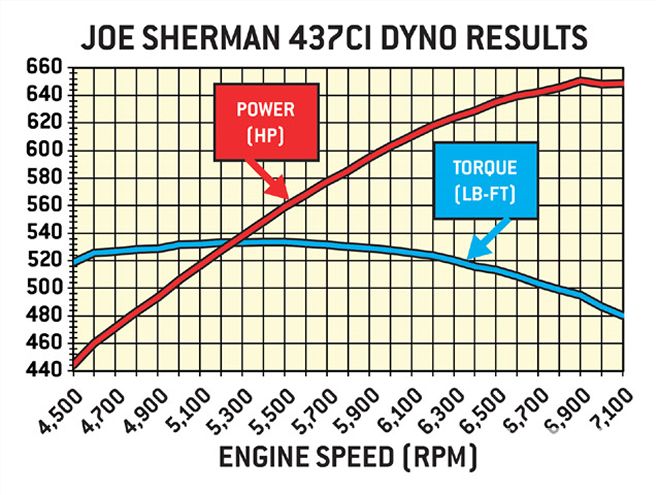

Dyno-Might

All the modern tech paid off when the motor was run on Sherman's SuperFlow dyno. Despite its 11.0:1 compression ratio, the engine's cranking compression was still a reasonable 195 psi, which in Sherman's experience is safe on 91-octane unleaded street gas in the hands of a competent tuner. In fact, the engine performed best with 40 degrees of total ignition advance. Running 1 7/8-inch primary-tube headers and 3-inch spacers under the 750-cfm Edelbrock carbs, the engine made a peak 650.5 hp at 6,900 rpm and 533.8 lb-ft at 5,500 rpm. The spacers proved to be worth about 20 hp compared with the no-spacer configuration. Sherman attributes this sterling output primarily to the Edelbrock heads, Comp cam, modern CP piston and ring technology, and the GZ vacuum pump. One could only imagine what World's forthcoming 500ci-capable aluminum block will be capable of. But 650 hp is definitely no slouch in a 50-year-old mill, with the bonus that the engine under the hood will have a distinctive look all its own.

Not only did the engine peak at 650 hp, but it also made more than 500 hp from 5,000 to 5,900 rpm and more than 600 hp from 6,000 on up. Total torque output was more than impressive with a very broad, flat curve: The engine pounded out more than 525 lb-ft from 5,000 through 6,100 rpm.

Not only did the engine peak at 650 hp, but it also made more than 500 hp from 5,000 to 5,900 rpm and more than 600 hp from 6,000 on up. Total torque output was more than impressive with a very broad, flat curve: The engine pounded out more than 525 lb-ft from 5,000 through 6,100 rpm.