If you haven't experienced the smell from burning fresh paint off of four new sets of headers in one day, you don't know fun.

If you haven't experienced the smell from burning fresh paint off of four new sets of headers in one day, you don't know fun.

It's been a while, but we finally dragged out the Circle Track dyno mule for a new round of testing. This time around the idea came from a bench racing session where we were talking about different header designs and how they are "supposed" to affect an engine's performance. For example, unequal-length headers are popular in dirt classes where the tire size is limited (like IMCA Modified) because the common thinking is that while these headers do not produce the most power, they are less peaky and can help limit wheel spin. It's one of those things we've always assumed was true, but hadn't tested.

So with that idea, we called up Doug Schoenfeld at Schoenfeld Headers to develop a plan using Circle Track's dyno mule as a test bed. If you've been a racer for any length of time, you've probably already heard of Schoenfeld Headers. It is one of the most popular header manufacturers in the racing industry. Schoenfeld is known for producing a product that is consistent from one header to the next, is affordable for the average racer, and, most of all, makes good power. Choosing Schoenfeld Headers as a partner for this test was a no-brainer.

Before testing could begin, we spent a lot of time setting our engine's parameters to ensure as much consistency as possible for each dyno pull. Here, instructor Doug Wolf sets the hot lash to 0.014 for the intake valves and 0.016 for the exhausts.

Before testing could begin, we spent a lot of time setting our engine's parameters to ensure as much consistency as possible for each dyno pull. Here, instructor Doug Wolf sets the hot lash to 0.014 for the intake valves and 0.016 for the exhausts.

We also enlisted the help of the NASCAR Technical Institute (NTI) in Mooresville, N.C. NTI is a technical training school that combines general automotive educations with an advanced regimen specializing in stock car racing. In addition to fabrication, pit crew training and other racing-specific courses, NTI also offers its students an engine-building program stocked with two dyno cells (one engine dyno and one chassis dyno) and more NASCAR Sprint Cup engines than most single-car teams. NTI has provided the engine dyno facilities in all of our previous tests (oil pans and rocker arms). It not only provides expertise in getting good, reliable dyno results, but its teachers also have a wealth of general engine-building knowledge which is invaluable.

While Schoenfeld Headers provided the test components, Circle Track provided the engine and NTI provided the dyno facilities, it was the NTI students who provided almost all of the labor installing the engine on the dyno, switching out the headers and even logging the dyno pulls themselves (under instructor supervision). An added bonus to the story was that the students got to see firsthand how header selection can affect performance of a race-engine package. In all of our previous tests with NTI, we've been impressed with the knowledge of the instructors as well as the quality of the students and were eager to work with them again.

The Test We settled on three different header tests for our dyno session that covered some of the biggest design decisions most racers face: Stepped versus straight tubes, equal-length versus unequal-length primaries and four-into-one collectors versus Tri-Y collectors. By combining different headers with similar characteristics, we were able to eliminate several variables as well as use only four different sets of headers (instead of six) for the three tests. We did this by making one set of headers our baseline, Schoenfeld part number 1024LV. The baseline headers were a stepped tube design that expanded to 17/8-inch with a four-into-one collector and unequal-length pipes. All four headers were 18 gauge mild steel with identical flanges and all four started with 13/4-inch primaries.

Instructor Rick Touchette sets the timing at 38 degrees advanced-the same as all of our previous tests with this engine.

Instructor Rick Touchette sets the timing at 38 degrees advanced-the same as all of our previous tests with this engine.

The first test would compare a stepped-tube header to a straight-tube header design. The headers to be compared (part number 1024L) to the baseline have all the same features except the primaries are 13/4-inches all the way to the collector.

For the second test, we used Schoenfeld Headers' part number 1014LV to compare an unequal-length design (the baseline) to a set of headers with equal-length primaries. Again, all other variables were the same. Both stepped from 13/4 to 17/8 inches, and both used a four-into-one collector.

All the headers for this test were supplied by Schoenfeld Headers. Our baseline was a 13/4- to 17/8-inch stepped design with unequal-length primaries and a four-into-one collector. It produced better numbers than our old 15/8 headers, but Schoenfeld had designs that proved even better.

All the headers for this test were supplied by Schoenfeld Headers. Our baseline was a 13/4- to 17/8-inch stepped design with unequal-length primaries and a four-into-one collector. It produced better numbers than our old 15/8 headers, but Schoenfeld had designs that proved even better.

Finally, for the third test we switched to part number 1024VY. This is Schoenfeld's Tri-Y collector design. And again, both the baseline and test headers had stepped, unequal-length primaries.

The Engine During each round of dyno tests, we've improved our dyno mule slightly. It began as a stock Chevy crate long block with a cast crank, cast pistons, 8.50:1 compression and four-bolt main caps. It was outfitted with a Weiand Action Plus dual-plane intake, a Holley 650 cfm four-barrel carb, a one-inch open carb spacer, and a CV products water pump and pulley set. We kept the seven quart Champ Pans competition pan from that test and averaged 355 pounds of torque at 3,600 rpm and 275 horsepower at 4,400 rpm.

The next test involved swapping out different rocker designs by Comp Cams. In order to better stress the rockers, we ditched the stock cast-iron cylinder heads for a pair of as-cast heads from RHS that featured 64cc chambers, 2.020 intake valves, 1.600 exhaust valves, and 200cc intake runners which flowed significantly better. They were assembled with beehive springs that tested around 180 pounds on the seat. We also went with Comp for a solid roller camshaft that gave this engine quite a bit more snort than the mild stock cam. It is ground with 0.400 lobe lift (for 0.600 total lift when matched with our 1.5:1 rockers), and the solid roller lifters are also from Comp. We tested six different rocker arms during that two-day session, and for this go-round we kept the Comp Cams steel Pro Magnum 1.5:1 rockers which produced 401.7 pounds of torque at 4,600 rpm and 401.1 horsepower at 5,700 rpm because they are most typical of what can be found on a high-end race motor.

The straight-tube headers had a tube diameter of 13/4 inches all the way to the collectors.

The straight-tube headers had a tube diameter of 13/4 inches all the way to the collectors.

Because we are striving for the most consistency possible from one dyno pull to the next, we didn't tune the engine for maximum power. Timing was set at 38 degrees with the advance locked out. The Holley carburetor was set up with No. 70 jets at all four corners, and seven quarts of synthetic racing oil was used for lubrication. Although different headers may perform better with different amounts of jetting in the carburetor or different timing settings, those factors did not change throughout the tests. Also, when each pull was made, lead instructor Doug Wolfe made sure that the water and oil temperatures were as consistent as possible. Our targets for the beginning of each pull were 190 degrees F for the oil and 180 for the water. For each header, we made two back-to-back pulls to make sure we were getting consistent numbers. We've printed the output numbers for the second of each of the pulls for this article, starting on p. 78.

The Baseline In previous tests we used a borrowed set of headers because NTI had them handy and they fit the dyno. We're not even sure of the brand, but they used a 15/8-inch primary with no steps. Using those headers with Comp's Pro Magnum rockers (the same used throughout these tests), peak power was 401.7 lb-ft of torque at 4,600 rpm and 401.1 hp at 5,700 rpm. Since our last test, NTI had also recalibrated its dyno and pulling back up the old tests with the new calibration, the peak numbers for both horsepower and torque increased by two (403.7 and 403.1, respectively).

After giving Doug Schoenfeld our engine's specifics, he chose a larger, 13/4-inch primary tube for our headers, and the choice was a good one. Our new baseline headers dropped a bit in peak torque with 386.1 at 4,600 rpm, but it significantly opened up the torque curve. Torque stayed higher in the upper rpm ranges which bumped peak horsepower up to 416.4 at 5,900 rpm. An improvement of 13.3 ponies! For each test we also recorded average torque and horsepower numbers in an rpm range most racers typically see in short-track racing. Our rpm range was between 4,300 and 6,300, and for our baseline headers the averages were 375.36 lb-ft of torque and 377.73 hp.

After each test, NTI's students swarmed the engine to make the header swap and get things going again as quickly as possible to minimize potential variables between each dyno pull.

After each test, NTI's students swarmed the engine to make the header swap and get things going again as quickly as possible to minimize potential variables between each dyno pull.

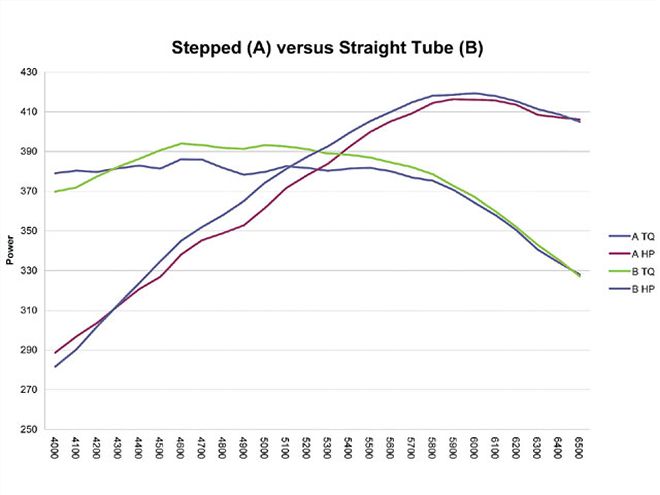

Stepped versus Straight Tubes In racing applications, stepped-tube headers are preferred because they can help improve scavenging and broaden the torque curve. That's what we were looking for here, and this is also where we got our first surprise.

In our tests the straight-tube headers with a consistent 13/4-inch diameter outperformed our 13/4 to 17/8 stepped-tube baseline headers all around. Peak torque was 394.0 at 4,600 rpm and horsepower was 419.3 and 6,000 rpm. Those are improvements of 7.9 lb-ft of torque and 2.9 hp. Average numbers also improved to 381.5 for torque (an improvement 6.14) and 383.71 for horsepower (an improvement of 5.98).

The most likely reason for this improvement is that the 13/4 to 17/8 combination is just slightly too large for this engine package and it responded better to the slightly smaller average diameter of the 13/4-inch straight-tube pipes. It definitely was scavenging better in the upper rpm range. By looking at the brake specific fuel consumption (bsfc), which is the pounds of fuel the engine burns in one hour to produce one horsepower, you can see how efficiently an engine is working. More horsepower at a lower bsfc means that the engine is burning more of the available fuel droplets during the combustion cycle. But when the combustion chamber does not change, as in our case, a higher bsfc usually equates to more horsepower. At peak rpm the straight-tube headers produced a bsfc of 0.538 while the baseline at the same rpm was 0.535. It is a small amount, but it does show that the straight tube headers were scavenging better in the upper-rpm range and allowing more fuel to be pulled into the combustion chambers to be burned on the power stroke. Also notice that just when the dyno pull ended at 6,500 rpm the stepped-tube headers were taking over with more power. If this engine were able to breathe a little better and rev higher, the stepped-tube headers would begin stacking up better.

There wasn't much difference between Schoenfeld's equal-length design (shown here) and the unequal-length header we used for the baseline.

There wasn't much difference between Schoenfeld's equal-length design (shown here) and the unequal-length header we used for the baseline.

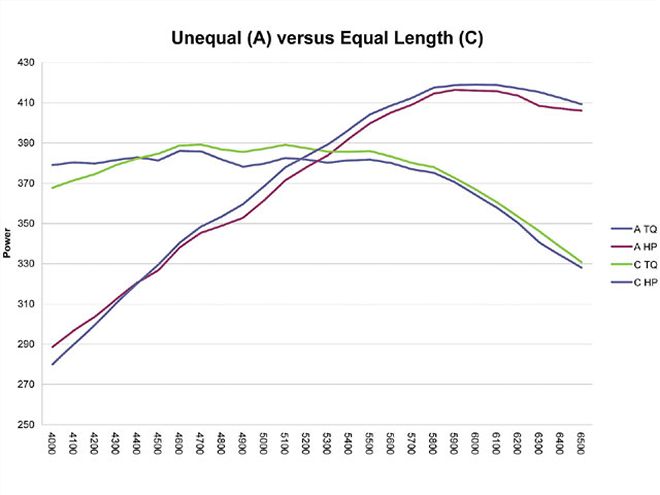

Unequal- versus Equal-Length Primaries Unequal-length headers are popular in classes where the available traction is limited. The thinking is that unequal-length tubes, while they can create less peak power than equal-length tubes, spread out the torque curve and help make a race car more driveable.

In our second test we pitted a set of Schoenfeld's equal-length headers against our unequal-length baseline set. To be honest, however, the difference between the two is minor. But the results on the dyno were noteworthy. At the low end of the range, the unequal-length baseline headers were better, but the equal-length pipes started producing more power at 4,400 rpm. After that, the numbers were higher for the equal-length pipes all the way through the rest of the pull. Peak torque moved up a notch and showed up at 4,700 rpm (389.3 lb-ft) and horsepower peak also moved 100 rpm higher where it was 419.1 at 6,000 rpm. Surprisingly, both peak numbers were better than our baseline-3.2 and 2.7, respectively-and the average numbers were also better.

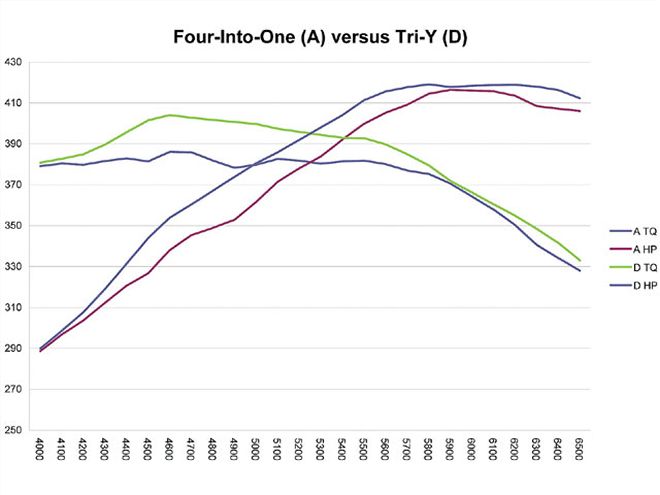

Four-Into-One versus Tri-Y Collectors Our third and final test moved away from the primary tubes and pitted the two most popular collector designs against each other. Four-into-one collectors-where all four primary tubes on each side dump into the same collector at the same spot-have been the standard for years, but Tri-Y collectors-which are a set of three two-into-one collectors arranged in sequence-are gaining ground. They were developed by high-end race teams, and their added complexity usually makes Tri-Y headers cost a little bit more, but they are catching on among Saturday night race teams.

Tri-Y headers use a more elaborate collector design that pairs different tubes together to create a stronger scavenging effect. The headers are more expensive, but in the right situation they are worth it.

Tri-Y headers use a more elaborate collector design that pairs different tubes together to create a stronger scavenging effect. The headers are more expensive, but in the right situation they are worth it.

Collector design is important because it can greatly affect scavenging. When the exhaust valve opens at the end of the power stroke, the exhaust flow isn't a steady stream out of the exhaust port and into the header tube. Instead, it is a strong pulse of high-pressure gas. Right behind that high-pressure pulse is a pulse of low pressure. It is this low pressure pulse that can help pull additional exhaust gasses out of the port ahead of the piston rising. The measure of how well an engine removes burnt exhaust gasses and replaces it with a fresh air/fuel charge is called its volumetric efficiency (VE). At low rpms, it is easy for an engine to have a VE very close to 100 percent, but as the rpms rise, it becomes more difficult to get complete cylinder filling in most engines and VE drops. But a good header design with a collector that best matches the engine package can significantly improve VE. In fact, in NASCAR Sprint Cup engines that have a well-matched intake and exhaust system, VE can actually be up over 100 percent. That's impossible in our engine and unlikely in all other race engines where rules limit carburetor size and the types of cylinder heads allowed, but good collector design can help improve the VE in any engine.

The trick in Tri-Y headers is that because the tubes are matched up in pairs, the exhaust pulse can pull more strongly on the mating tube, having a better scavenging effect in that cylinder. This means that if the collector lengths are right for that engine package and the tube pairings match up well with the firing order, Tri-Y headers can produce improved power over similar four-into-one headers. But if the package isn't optimized things can go bad quickly. In fact, Schoenfeld Headers specifically says that these Tri-Y headers we are testing do not work well on an engine with a 4-7 cam swap.

Note the difference in the torque curve. We were surprised when the straight tubes performed better than the stepped ones.

Note the difference in the torque curve. We were surprised when the straight tubes performed better than the stepped ones.

With our package, at least, Schoenfeld's Tri-Y design worked wonders. Peak torque was 18 better than our baseline at 404.1 lb-ft and horsepower was 2.7 better at 419.1. Average torque jumped all the way up to 386.98 (an improvement of 11.62 across the range) and power was up to 388.91 (11.18 better). The Tri-Y headers, in fact, produced the best average torque and horsepower numbers of any header combination we tested. This definitely is the way to go with our engine.

Conclusion Here comes the tough part. Unlike the previous tests where we were able to separate oil pan and rocker arm performance from the rest of the engine package, header performance is critically dependent upon the design and performance of the rest of your intake and exhaust system. For example, had we used a single-plane intake manifold instead of our Weiand dual-plane intake, the results could have been completely different. The same holds true if we had used a different set of cylinder heads, camshaft, and even the length of the exhaust pipe after the header collectors.

With our particular engine combination, the data shows that Tri-Y headers are definitely the way to go.

With our particular engine combination, the data shows that Tri-Y headers are definitely the way to go.

So, while we cannot unequivocally say that Tri-Y headers are the best design for your race engine, we can say that small changes in the way a set of headers are constructed can have a significant effect on your engine's performance. In fact, finding the set of the headers that best compliments your engine package can significantly improve power.

And, as NTI instructor Rick Touchette points out. Any power gains made by improving your header's performance is "free power." The power isn't made by bolting on ultra-light (but weaker) rocker arms that may break unexpectedly or lighter oil pressure that may require you to go through more frequent rebuilds. This power is made by helping pull more fuel into the combustion chambers, and as long as your rods and pistons are strong enough to withstand the extra horsepower generated, additional power causes no more stress on your race engine.

There was less of a radical difference when comparing unequal- versus equal-length headers.

There was less of a radical difference when comparing unequal- versus equal-length headers.

From our findings, it's definitely worthwhile to spend a little time investigating which headers will work best for you. The first step is to get on the phone with your header manufacturer's technical representatives and make use of their knowledge. Good header manufacturers spend a lot of time testing different header designs against just about any engine package you can think of, and their R&D experience can be invaluable. Also, if you really want to know for sure what works best for you, buy several. Headers aren't so expensive that most teams cannot afford to invest in a few sets for testing. Maybe you can even go in with a few other race teams (that all run Chevy's or Fords) and agree to buy and share several R&D sets so that all of you can test and see what works best for you.