Factory production vehicles haven't rolled off the Big Three's assemblyline with new carburetors since the '80s, but it's still the mostpopular choice of induction among car crafters. Don't get us wrong; weunderstand that the latest and greatest computerized fuel-injectionsystems are getting more affordable and enable today's performancetuners to tame mega-horsepower engines for docile street use, but nomatter how you look at it, carburetors will always be cheap andeffective if you know how to properly tune them. But carb experts--theguys who spend all day on the phones with real-world users--tell us itnever ceases to amaze them how many people are completely lost when itcomes to understanding the nitty-gritty details of how a carb reallyworks and how to tune one for maximum performance.

Over the years we've shown our readers everything from how to rebuildcarburetors to how to live with one every day. This time we're going astep further by directly probing minds from Holley Performance, DemonCarburetion, and Edelbrock for answers to 20 of the most commoncarburetion questions from basic to advanced. Even you expert carb gurusout there might learn something new.

Q: Does a bigger carb make more power? What's thelimit?

Demon Carbs responds: Larger carburetors can make morepower on a dynamometer, but this can also result in slower accelerationand lower efficiency of fuel atomization. Generally we find that you'rebetter off leaning towards a slightly smaller carburetor than a largerone, as it'll operate more efficiently and provide better accelerationfor the vehicle.

Q: Where should I hook up my vacuum advance?

Edelbrock responds: If you're unsure of which port touse, connect the vacuum line to the timed vacuum port. This has novacuum at idle and won't affect idle quality. However, if yourapplication requires vacuum at idle, you'll want to connect the line toa manifold vacuum port. The most detrimental effects of using the wrongport is an increase or decrease of rpm and poor idle characteristics.Generally the distributor vacuum line goes to the timed port.

Q: What's the best way to tune the accelerator-pumpcircuit?

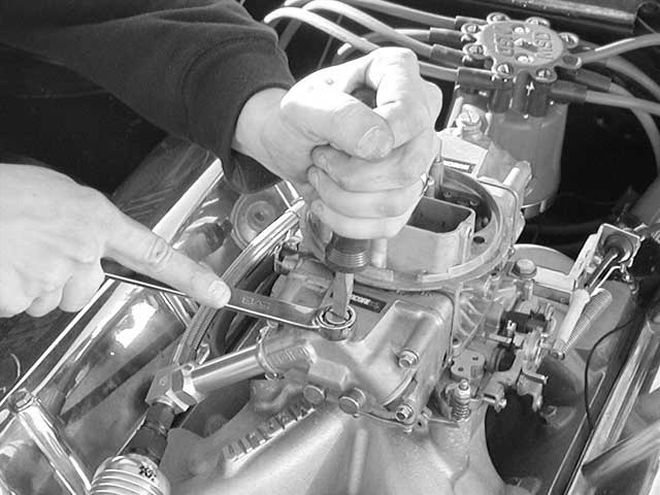

Holley Performance responds: The accelerator-pumpsystem consists of three main components: the pump diaphragm, the pumpcam, and the pump nozzle. This is the carburetor system that is mostresponsible for having good, crisp, off-idle throttle response. Itspurpose is to inject a certain amount of fuel down the throttle boreswhen the throttle is opened to smooth the transition between the idleand main circuits so that no stumble, hesitation, or sluggishness willbe evident during this transition phase.

The first adjustment to check is the clearance between the pumpoperating lever and the pump diaphragm cover's arm, at wide-openthrottle. This clearance should be around 0.015 inch. This ensures thatthe pump diaphragm is never stretched to its maximum limit at wide-openthrottle, which will cause premature pump failure. Next, make sure theaccelerator-pump arm is activated the moment that the throttle begins tomove, which ensures instantaneous pump response. These adjustments canbe made by simply turning the accelerator-pump adjusting screw locatedon the accelerator-pump arm together with the pump override spring andlocknut.

The amount of fuel delivered by one accelerator-pump stroke isdetermined by the pump's capacity and the profile of the pump cam. Thetime it takes for that fuel to be delivered is controlled by thepump-nozzle size. A larger pump nozzle delivers the fuel much soonerthan a smaller pump nozzle. During acceleration tests, if you noticethat the car first hesitates and then picks up, it's a sure bet thepump-nozzle size should be increased. A backfire (lean condition) onacceleration also calls for a larger pump-nozzle size. Conversely, ifoff-idle acceleration does not feel crisp or clean, the pump-nozzle sizemay need to be decreased. Holley accelerator-pump nozzles are stampedwith a number that indicates the drilled pump hole size. For example, apump nozzle stamped "35" has a 0.035-inch orifice. Pump nozzle sizes areavailable from 0.025 to 0.052 inch. Whenever a 0.040-inch or largeraccelerator-pump nozzle is installed, the "hollow" pump-nozzle screw (PN26-12) should also be used. This screw allows extra fuel to flow to thepump nozzle, assuring that the pump nozzle itself will be the limitingrestriction in the accelerator-pump fuel-supply system.

When changing the pump nozzle, it's best to jump three sizes. Forexample, if there's an offline hesitation with a No. 28 pump nozzle, trya No. 31 pump nozzle. If you must use a No. 37 (0.037-inch) or largerpump nozzle, then also use a 50cc pump. A 50cc accelerator-pumpconversion kit is available under Holley PN 20-11 when maximum pumpcapacity is desired.

Once nozzle size has been selected, the accelerator-pump system can befurther tailored with the pump cam. Holley offers an assortment ofdifferent pump cams, each with uniquely different lift and durationprofiles that are available under Holley PN 20-12. The cam profileaffects the movement of the accelerator-pump lever and, subsequently,the amount of fuel delivered by the pump nozzle.

Installing a pump cam is a simple matter of loosening one screw, placingthe new pump cam next to the throttle lever, and tightening it up. Thereare two or three numbered holes in each pump cam. Placing the screw inposition number 1 activates the accelerator pump a little early,allowing full use of the pump's capacity. Generally, vehicles thatnormally run at lower idle speeds (600 or 700 rpm) find this positionmore useful because they can have a good pump shot available comingright off this relatively low idle. Positions number 2 or 3 delay thepump action, relatively speaking. These two cam positions are good forengines that idle at 1,000 rpm or above. Repositioning the camcompensates for the extra throttle rotation required to maintain therelatively higher idle setting. Pump-arm adjustment and clearance shouldbe checked and verified each and every time the pump cam or pump-camposition is changed.

Q: How do I choose the right size carburetor for myengine?

Edelbrock responds: A simple formula can assist youwith this. Multiply your cubic-inch displacement by the maximum rpmlimit and then divide by 3,456 to represent the volumetric efficiency.The result is the amount of cfm the engine requires at the maximum rpmlimit.

Example:

350 ci x 6,000 rpm = 2,100,000

2,100,000 / 3,456 = 608cfm

A 600-cfm carb would would be sufficient.

Q: Is air pushed or sucked into a carburetor?

Demon Carbs responds: Unless you are working with aforced-induction system (centrifugal supercharger or a turbochargersystem) that forces air through the carburetor, air is pulled throughthe carburetor based on the engine's vacuum signal.

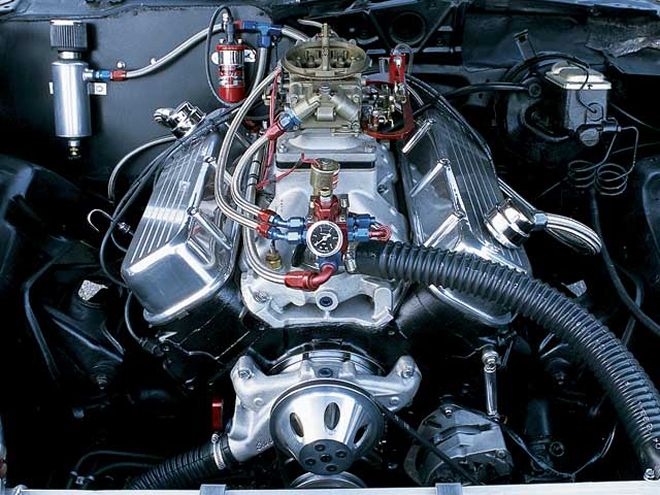

Q: Where should the fuel-pressure regulator be located and whattype should I use?

Demon Carbs responds: The pressure regulator should bemounted as close as possible to whatever you're feeding (e.g.,carburetor, nitrous system). The farther away the regulator is, thelonger it will take to open and close in response to demand, which cancause spikes in fuel pressure. The type of fuel pump you're using alongwith the fuel requirements of the engine will be the determining factorsfor the type of regulator you'll use.

Q: How does a metering rod work and how do I tune withone?

Edelbrock responds: Fuel must pass through therestriction created by the main jet and metering rod before entering theengine. The rod extends through the jet, reducing the amount of area forfuel flow. Similar to power valves, metering rods add fuel when acertain engine load or vacuum drop is reached. The two metering rods inan Edelbrock carb have stepped ends that protrude into the main jets andrestrict or increase the flow of fuel through the orifice proportionalto engine load. If the diameter of the rod is large, then fuel flowthrough the jets is more restricted than if the rod were small.Specially tuned springs are used to adjust the vacuum levels required toactuate the rods under various load conditions. There is no"pre-determined" combination of rods and jets for any given engine. Eachengine may require a different fuel curve. The best thing to do is runthe carburetor on the engine right out of the box, then check the sparkplugs and see how they look. You need to have a golden brown color onthe plugs. If they are too white or too black, you need to makeadjustments.

Q: How do I know what size power valve to use?

Holley Performance responds: The power-enrichmentsystem supplies additional fuel to the main system during heavy-load orfull-power situations. Holley-style carburetors utilize avacuum-operated power-enrichment system and a selection of power valvesis available to "time" this system's operation to your specific needs.

Each Holley power valve is stamped with a number designating the vacuumopening point. For example, a "65" indicates that the power valve willopen when engine vacuum drops to 6.5 in-Hg or lower. An accurate vacuumgauge should be used when determining the correct power valve to use.

A competition or race engine with a long-duration high-overlap camshaftwill have low manifold vacuum at idle speeds. If the vehicle has amanual transmission, take the vacuum reading with the engine warmed upand at idle. If the vehicle is equipped with an automatic transmission,take the vacuum reading with the engine warmed up and idling in gear. Ineither case, the power valve selected should have a vacuum opening pointabout 2 in-Hg below the intake-manifold-vacuum reading taken.

A stock engine, or one that is only mildly built for street use, willhave high manifold vacuum at idle speeds. To determine the correct powervalve, drive the vehicle at various steady speeds and take vacuumreadings. The power valve selected should have an opening point about 2in-Hg below the lowest steady-speed engine vacuum observed.

Most popular Holley performance carburetors incorporate apower-valve-blow-out protection system. A special check valve is locatedin the throttle body expressly for this purpose. This check valve isdesigned to be normally open but will quickly seat to close off theinternal vacuum passage when a backfire occurs. Once closed, the checkvalve interrupts the pressure wave caused by the backfire, thusprotecting the power valve.

Q: How much clearance should I have from the top of the venttube to the lid of the air filter?

Edelbrock responds: A minimum of 3/4 to 1 inch isrecommended for proper airflow.

Q: How do an air door, an air-valve secondary, and vacuumsecondaries differ?

Edelbrock responds: An air door is typically acounterweighted set of throttle blades that operate separately from theactual throttle blades of the carburetor but is located inside thecarburetor body. It is only accessible by removing the top of thecarburetor and is not easily adjustable. The purpose of an air door isto allow a smooth transition from the primary circuit into the secondarycircuit. Rather than giving 100 percent of the secondary's "flow" all atonce to the engine, the counterweighted air door opens gradually as thedraw from the engine increases with rpm, therefore slowly allowing moreair and fuel into the engine.

An air valve operates pretty much the same way as an air door, but it isnot located inside the carb, and it is adjustable. This is aspring-loaded air valve, or "flap" that sits in the top portion of theair horn of the carburetor, and you can adjust the amount of tension onthe valve by means of a screw. Making the tension tighter brings thesecondary's full potential in later in the rpm range, and loosening thetension brings it in earlier.

Vacuum secondaries typically only apply to Holley-style carburetors.This is a diaphragm with a spring inside that sits off to the side ofthe carburetor but is still part of the carburetor and operates thesecondaries using the engine's manifold vacuum. It is adjustable bymeans of a spring that can be removed and replaced inside the diaphragm.

Q: Why is it necessary for a blower carb to be boostreferenced?

Holley Performance responds: A carburetor does notsense the vacuum of the engine when there is a supercharger between thecarb and engine. This lack of vacuum causes the power valve to remainopen. Referencing the power valve to the lower intake allows the powervalve to operate properly, giving precise fuel metering as you wouldachieve without the supercharger. If the power valve is not referencedto the lower intake, it can be sucked shut from the high vacuum signalfrom the blower. This will cause the engine to run 6 to 8 jet sizes toolean, possibly causing engine damage.

Q: How is jet size determined and why do two jets with the samehole sometimes flow differently? Can I just drill jets to a biggersize?

Holley Performance responds: There is a basicmisconception that size alone determines jet flow characteristics. Thisis not the case because the shape of the jet entry and exit, as well asthe finish, affects flow. Holley jets are finished-drilled in anenvironmentally controlled room so tolerances are as close as possibleeach time a set of jets are run. Holley takes into consideration the jetentry, exit, and finish as a constant variable. Samples are taken atvarious times during each jet run to be sure the machines are holdingtolerances and flow. These hole sizes are measured in thousandths andthe jet part number generally matches the hole size--give or take onethousandth--on jet sizes up to 70. For example, a PN 122-44 jet has ahole size of 0.044 inch. Above a 70 jet, the hole sizes aresignificantly larger than the number.

Holley has allowable tolerances for each standard jet size, whichexplains why some jets with the same number can seem to flowdifferently. For example, the tolerance range on a 65 jet ranges from351.5 to 362 cc per minute while a 66 ranges from 368.5 to 379.5 cc's.Those tolerance ranges explain why a 66 jet may not always give a richermixture than a 65--if the 65 is on the "high" side of the tolerance andthe 66 is on the "low" side. The two jets may flow very close to thesame.

Holley offers close-limit jets that range in size from 60 to 74. The jetnumbering follows that of a standard jet with a third number added. Forexample, a jet stamped with PN 122-632 indicates it is a 63 jet. Thethird number, 2, is added to indicate whether the jet flows on the leanside (631), the middle (632), or the rich side (633) of the flow band.There is about a 1.5 percent difference in flow between each of thethree jets in a flow band, for a flow range difference of 4.5 percent.Holley close-limit jets are only offered in the middle flow range.

Drilling out jets is never recommended because this always alters theentry and exit features to some degree and may introduce a swirl patterneven if the jet is held in a pin vise and carefully drilled. You cannotbe sure of the flow characteristics of a jet that you modify bydrilling--unless you can get that jet back on a flow machine to compareit with a standard jet.

Q: How do you tune a vacuum-operated secondary?

Holley Performance responds: Carburetors withvacuum-operated secondaries are popular for street vehicles because theyare very forgiving, and correct carburetor size selection is not ascritical as with mechanical-secondary carburetors. The vacuumsecondaries only allow the carburetor to flow the necessary air and fuelbased on the engine's demand. Vacuum for the diaphragm is obtained fromthe primary venturis with some being bled off through an opening intoone of the secondaries. As engine rpm goes up, velocity through theprimaries creates a vacuum signal. The amount of secondary opening isinitially dependent on airflow in the primaries but is later augmentedby the vacuum in the secondary barrel through the previously mentionedbleed opening. If a carburetor is too large for an engine, the vacuumdiaphragm "sizes" the carburetor so it flows only the necessary amountby partially opening the secondaries.

Tuning the vacuum secondaries is very simple. Holley offers color-codedsprings of various tensions. This enables the engine's vacuum to pullopen the secondaries either sooner or later depending on the springtension. White springs are the lightest and allow the secondaries toopen sooner, while black Holley springs delay secondary opening thelongest and open them at the slowest rate. Holley spring kit PN 20-13includes seven springs for proper tuning.

Q: How do you set the float level and what effect does ithave?

Demon Carbs responds: For street-driven Demoncarburetor applications, we recommend starting with the float level 1/4up the sight window. Changing the float level changes the amount of fuelin the bowl (reservoir) to feed to carburetor jets. Raising the floatlevel can help the engine respond quicker if you're having a leanstumble, while lowering the float level can delay the start of the mainmetering circuit, in effect helping lean the mixture coming off idle.

Q: We've seen some carburetors with drilled throttlebutterflies. Why and when is it necessary?

Holley Performance responds: Yes, some Holley carbs docome with drilled butterflies. Typically these are found on ourHP-series carbs. This was a performance feature that we added becausethese carburetors are mostly purchased for high-performance race enginesthat require extra air when the butterflies are closed to idle properly.Sometimes drilling the butterflies is required on carburetors forengines utilizing a cam with a narrow lobe separation, which in turncreates low manifold vacuum. The large cam requires more air and fuel toidle. Most people open the curb idle screw so much that the butterfliesopen far enough to expose the main circuits, causing engine rpm to jumpso high that turning the idle-mixture screws have no effect on enginerpm. Usually this condition can be corrected by closing the curb idlescrew down to just below the idle transfer circuit slot and opening upthe secondary throttle blades with the secondary-throttle-blade screw.Many people are not aware that there is a secondary-throttle-openingscrew. In rare occasions, drilling the butterflies would still berequired if opening up both sets of throttle blades did not provideenough air for the engine.

Q: When should I use a double-pumper instead of avacuum-secondary carb?

Demon Carbs responds: Generally you should use amechanical-secondary carburetor on vehicles equipped with manualtransmissions or with an automatic transmission using a3,000-rpm-or-higher stall converter. On automatic-transmission-equippedvehicles with less than 3,000-stall converters, the vacuum-secondarycarburetor is the best choice because the design of the double-pumpercan dump so much extra fuel into the engine that a rich bog may occur.

Q: How do you diagnose the cause of a bog or stumble?

Edelbrock responds: There are different kinds of "bogs"and "stumbles"; each situation has a different meaning to differentpeople, and a different feel as well. You can have a lean bog or a richbog; you can have the same with a stumble. Keep in mind that a bog and astumble are pretty much the same thing. If the vehicle tends to fall onits face--step on the throttle and the engine just wants todie--typically this is a rich bog. If too much fuel enters the enginetoo soon and the engine can't handle it, it makes no power and doesn'twant to go anywhere. A lean bog or stumble would give more of a jerkymotion and tend to "pop" back through the carburetor. No matter whatsituation you encounter, you will need to check the basics first,including fuel pressure, float level, ignition timing, and spark plugcolor to determine which direction to go for the cure.

Q: What's the difference between a straight-leg booster, adown-leg booster, and an annular-discharge booster? Does booster designaffect jetting?

Demon Carbs responds: The straight-leg booster has, asthe name implies, a straight leg out from the main body with a dischargering above the carburetor's venturi. A down-leg or drop-leg boosterdrops the discharge ring lower into the venturi where it is in thehigher velocity airstream, which will pull more fuel than astraight-leg-style booster. An annular-discharge booster has a largerring with multiple discharge holes rather than the single outlet hole ofa straight-leg or down-leg-style booster. This creates a venturi insidethe main venturi that will create more vacuum signal to pull even morefuel. There are several pros and cons for each type of booster based onthe application they are installed on. If you were to run each style ofbooster in the same carburetor with all else being equal, the down-legbooster would require a smaller jet to flow the same amount of fuel thanwould a straight-leg booster, while the annular-discharge boosterrequires an even smaller jet to flow the same amount of fuel as thedown-leg booster.

Q: How does weather and altitude affect carb jetting?

Demon Carbs responds: Put very simply, the more oxygenthere is in the air, the more fuel--and therefore, the larger the jetsize--the engine needs. As the temperature gets colder or the altitudegets lower, there is more oxygen in the air, so you'll need to go up onthe jet size to add more fuel. Conversely, as it gets warmer or you gohigher in altitude, you'll need to go down on your main jet size.

Q: How do I know what size and type of needle-and-seat touse?

Holley Performance responds: Holley offers a variety ofneedle-and-seat assemblies for its carburetors. The configuration of theneedle-and-seat assembly and its seat size depend on carburetorapplication, cfm rating, and type of fuel bowl used.

Seat size determines the maximum amount of fuel that can flow through itat a given pressure. A bigger seat flows more fuel. Most Holleyperformance carburetors come with Viton-tipped needles. The Viton needledesign is resistant to dirt and conforms nicely to the shape of the seatfor superior sealing. For this reason it is not recommended to use asteel or titanium needle, except for racing. In street and mild raceapplications, a 0.110-inch Viton assembly (PN 6-504) is standard andflows sufficient fuel for carbs up to 850 cfm. Viton PN 6-518-2 has aseat size of 0.120 inch and is standard on carburetors like Holley's 950and 1,000 HP as well as Dominators.

Holley offers steel-tipped inlet needles that are necessary when usingexotic racing fuels or alcohol, or when using benzine or acetoneadditives. A 0.097-inch steel seat size should be used for smallfour-barrel carburetors; a 0.110-inch steel seat size should be used forcarburetors up to 735 cfm; larger seat sizes should be used withcarburetors 750 cfm and larger.

Holley also offers a titanium inlet needle with a 0.150-inch seat. Thisis about as big as you can get. Its design is very responsive to changesin flow rates and has excellent sealing capabilities.