No matter how well-tuned it is, your race engine is a grumbling beast. Consider that there are four controlled explosions with every turn of the crankshaft in a V-8 engine. At 7,000 rpm, the spark plugs fire off an air/fuel charge 28,000 times every minute.

From the driver's seat, it may feel like the engine is providing a constant source of power, but the events taking place inside reveal the contrary. When the cylinder fires, an expansion of gasses from the burning fuel places incredible amounts of downward pressure on the piston. Of course, that's what we want since the engine is supposed to burn fuel to produce horsepower. Unfortunately, that force is neither smooth nor consistent. The force of the burning fuel pushing the piston down the cylinder bore must be converted to a spinning force by the connecting rod and the arm on the crankshaft. Plus, when the piston is being pushed up the cylinder on the compression stroke, the force is acting in the opposite direction.

Piston movement turns the crank because the crank's rod journal is off the crank's centerline. The crank's rod journal acts as a lever arm attached to a shaft. The piston and rod push down on the lever arm, which rotates the shaft. That all sounds good until you consider that the force we are discussing is really a power pulse that comes from igniting the air/fuel charge. The pulse is resisted by the entire weight and inertia of the car, which the driveline is attempting to push forward. It is impossible to create a perfectly rigid crank, so some of the energy from the piston bends the lever arm and twists the crankshaft.

When the force is reduced enough for the crank to spring back, it doesn't just return to its original shape immediately. Instead, the force of untwisting causes it to shoot past its original shape and twist in the opposite direction. This twisting goes back and forth a number of times until the crank settles down. The number of times this event takes place and its duration depends on the crank's construction (cast, forged, billet), mass, and quality of materials.

The Role of the Damper On a V-8 crankshaft, eight cylinders are pushing and pulling on the crank's four rod journals at different times. Some are pushing down on the power stroke, while others are resisting the crank, pushing the cylinder up on the compression stroke. All these forces send vibrations hurtling up and down the crank, and the frequencies change with engine rpm.

When the engine moves through its rpm range, the speed at which the power pulses from ignition of the air/fuel mixture will eventually match the natural frequency of the crankshaft. When this happens, the vibrations moving through the crank will build upon each other and gain strength, often with damaging results. Running an engine without protection from these vibrations can cause flexplate or flywheel failure, loosened bolts, broken timing chains, along with erratic timing and valvetrain functions. The crankshaft will fatigue and eventually fail, usually at the snout.

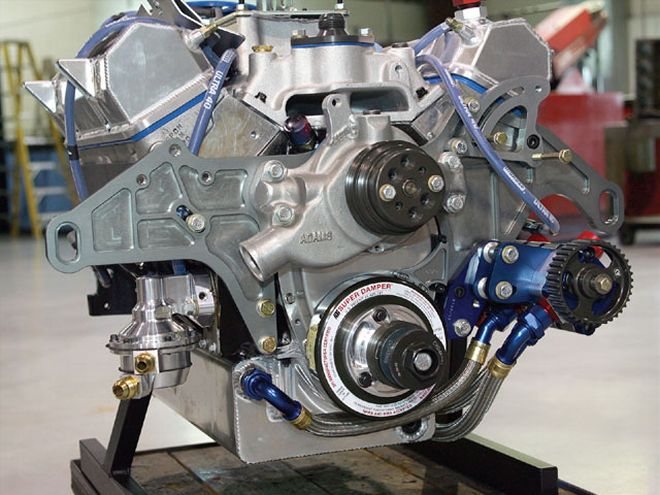

The purpose of the harmonic damper, of course, is to protect the engine from these damaging vibrations. Most quality harmonic damper designs reduce the vibrations traveling up and down the crankshaft by absorbing the vibrations and converting them to heat energy. Many racers use the words "balancer" and "damper" interchangeably, but since almost all race engines are internally balanced, "damper" is the more accurate term.

By the way, there is a good reason that the damper is attached to the front of the crankshaft. The flywheel and the resistance provided by the rear wheels absorb crankshaft harmonic vibrations at the back of the crank. So if you run an engine without a damper, the crank will show greater twist the farther you get from the flywheel. Since the timing chain is at the front of the crank, running without a damper (or even with a poor-quality, inefficient one) not only reduces crankshaft life, but also causes the ignition and valvetrain to behave erratically. And that can cost you power.

Bonded Rubber Designs By far the most accepted style of damper in high-performance applications is one that uses a ring of steel bonded to the damper body with a ring of rubber. The inertia that comes from the ring of steel causes the rubber ring to stretch and absorb the vibrations.

This is also the method most stock dampers use to control vibrations. The rubber is melted in between the inner and outer metal rings of a stock damper, which is tuned to work best at passenger car rpm levels. In high-rpm race applications, the stock damper usually does a poor job of counteracting harmonic vibrations. Also, when racing with an overmatched stock damper, there is a good chance that the outer steel ring will slip on the rubber ring. This throws off the timing marks and may cause you to improperly time your engine.

ATI is the leading manufacturer of dampers for performance applications. However, instead of the stock-style damper, ATI uses O-rings of different densities and hardness to bond the outer ring to the hub. This allows the damper to be tuned to the engine's size and intended rpm levels for maximum effectiveness at minimum size.

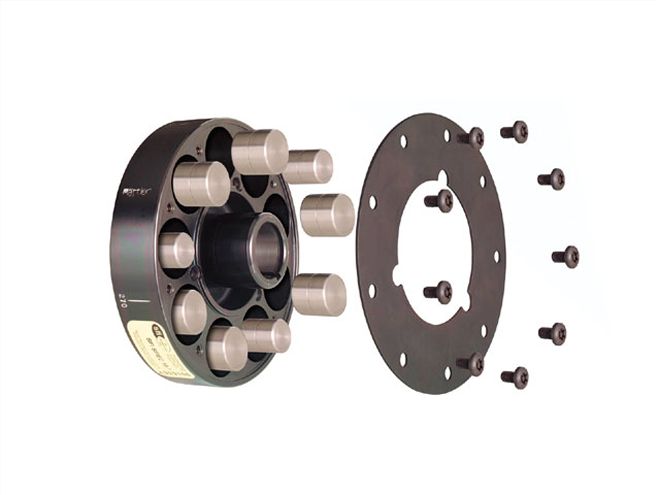

Another advantage of an ATI damper is that it can be easily rebuilt. ATI recommends rebuilding the damper every time the engine is rebuilt, but many engine builders say they are comfortable having their dampers rebuilt only at the end of the racing season. (For comparison, ATI says its dampers can last 10 years in passenger car applications before needing to be rebuilt.)

You can also rebuild a damper if it needs to be retuned for a different engine package. This, however, is relatively rare unless the changes to the engine are quite significant. ATI also recently released a rebuild kit for its dampers to allow racers and engine builders to rebuild their dampers in-house. This option is popular among engine builders, but if you are a single-car team, the most cost-effective option is to send your damper back to ATI for an annual inspection and rebuild.

Aftermarket dampers are quickly gaining in popularity in the crate motor classes, where their use is legal. J.C. Beattie Jr. of ATI recommends swapping out the stock damper whenever possible. "The biggest problem with OEM dampers is they just aren't precise," he says. "And the quality is not controlled to consistently dampen the same frequencies of torsional twist. OEM dampers were never meant to take the shock an engine sees when it hits the rev limiter repeatedly. The OEM damper will either spin the O.D. weight, or the damper will come apart completely."

In order to properly match the damper to your needs, Beattie recommends talking to the damper builder's customer service with the following information:

1.Brand of engine2.Inline or V style and number of cylinders3.Application (oval track racing) and number of laps in an event 4.Rpm operating range and redline5.Horsepower6. Weight and material of the crankshaft7.Rod and piston material

The New Kid on the Block Although most dampers use the bonded-rubber approach, there is one interesting design on the market that is quite different and also works quite well. TCI, a division of Comp Cams, has introduced its Rattler line of dampers for performance engines.

Its design works so well that TCI calls the Rattler a torsional vibration absorber instead of a damper because the design actively absorbs the vibrations to eliminate them. It is a pendulum-type design that uses steel rollers that fit loosely into holes inside the damper body. The rollers roll forward during compression strokes and backward during the power stroke to minimize the engine speed variations and vibration. TCI says the idea came from airplane engines but never caught on in automotive engines because it was very expensive to implement. TCI's design is the first to allow the pendulum damper to be effective and affordable for racing applications.

TCI says one of the advantages of the Rattler is its effectiveness at all engine speeds and not just a specific range. The Rattler is designed for the number of cylinders, not the operating range. Fortunately, TCI was able to design the Rattler to be sized and shaped like traditional dampers. That means you can use it in any stock car racing engine application without interference issues with the accessory drivebelts or the oil pan. No special tools are required to install or remove the unit.