We tend to take oil for granted, but as engine output continues to climb, the oil's job will get more difficult. We tested this Quaker State 5W20 against a more viscous 20W50 and saw a minor improvement in power.

We tend to take oil for granted, but as engine output continues to climb, the oil's job will get more difficult. We tested this Quaker State 5W20 against a more viscous 20W50 and saw a minor improvement in power.

The line in Hollywood is that you can't be too thin or too rich. When it comes to high-performance engines, it's better to be a little rich than too lean, but with engine oil, thinner is definitely better. The OEMs are constantly pushing the envelope when it comes to all things that affect efficiency. One of the latest trends is to use thinner viscosity oils in search of more power and better fuel mileage as long as the oil doesn't hurt durability.

Car crafters are always looking for that next performance advantage, especially if it doesn't cost much and all you have to do is open a bottle and pour it in. We decided to take a closer look at thinner viscosity oils and do some testing to see if we could find a little horsepower from a pour spout.

To begin with, we spoke to Quaker State engineer Mark Farner about what goes into this new generation of synthetic engine oils and what kind of advantages they promise. Synthetic engine oil has always enjoyed a reputation both for its high-pressure lubrication performance and also its ability to withstand much higher engine oil temperatures than conventional petroleum-based oil. Conventional oils will tolerate engine oil sump temperatures of up to 250 to as much as 275 degrees F without difficulty. According to Farner, oils like Quaker State's full synthetics can easily withstand sump temperatures in excess of 300 degrees F, and he says that some oval track race teams are experimenting with temperatures as high as 350 degrees F.

Just because you may never put 3,000 miles on your garage queen engine doesn't mean that you shouldn't change the oil. Water can combine with sulfur and fuel contaminants to create acids that can eat bearings. The pits in these bearings were created by acids.

Just because you may never put 3,000 miles on your garage queen engine doesn't mean that you shouldn't change the oil. Water can combine with sulfur and fuel contaminants to create acids that can eat bearings. The pits in these bearings were created by acids.

For a typical wet-sump engine, 300 degrees F is still extremely hot, but Farner says that synthetics, because of their molecular makeup, are better suited to withstand these temperatures. The downside is that additive packages do tend to break down faster in high-temperature environments, so if you plan on running oil temperatures in excess of 300 degrees, this would mean changing the oil after every track event regardless of the mileage.

For street engines that do not suffer this kind of track-day abuse, merely pouring in a synthetic does not mean that you can radically extend service drain intervals. Petroleum-based oils do not lose their base lubrication characteristics, what does suffer with use are the additive packages added to the oil. Synthetics are no different. Engines that see only limited use and ones that may never get up to full operating temperature can suffer from high levels of contamination that will require shorter drain intervals. For example, Farner says that for every pound of fuel burned in an engine, the combustion process also creates a pound of water. Some of this water will eventually end up in the oil pan. If the engine rarely sees sump temperatures that exceed 212 degrees F (water's boiling point), the water quickly mixes with another combustion byproduct--sulfur--to create acids that can eventually eat bearings if the oil is not drained.

Another reason to perhaps shorten drain intervals for performance engines is that oil is an important component of ring seal. If engine oil is contaminated with water, the water evaporates almost immediately around the rings, reducing ring seal and horsepower. Several years ago, we witnessed this firsthand at the U.S. Nationals when John Lingenfelter's small-block-Chevy-powered Pro Stock truck suffered an internal water leak. Once the water mixed with the engine oil, the 9,000-rpm engine lost double-digit power, which cost him the race.

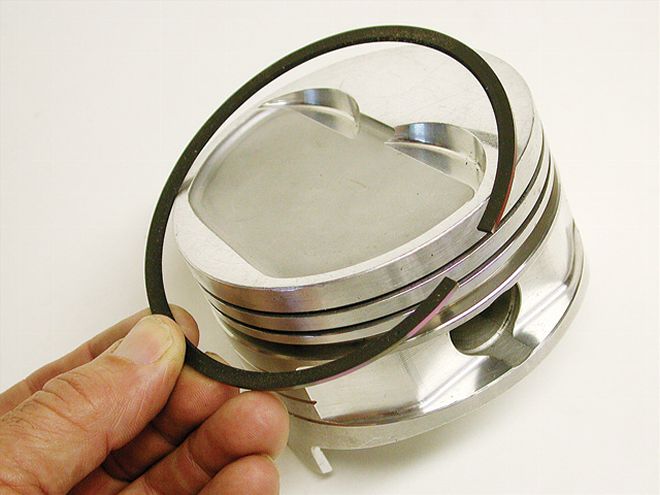

The ultimate seal with piston rings is assisted with engine oil. The highest friction loss in an engine is found between the rings and the cylinder wall. Quaker State's research indicates that a too-thin oil can actually vaporize at the top ring, sacrificing ring seal.

The ultimate seal with piston rings is assisted with engine oil. The highest friction loss in an engine is found between the rings and the cylinder wall. Quaker State's research indicates that a too-thin oil can actually vaporize at the top ring, sacrificing ring seal.

Fuel is another contaminant that is often found in engine oil. Fuel can enter the oil from several places, most commonly as blowby past the rings. Even though we think of fuel as easily evaporated, according to Farner only the light ends of fuel evaporate at room temperatures. The heavier ends require temperatures as high as 450 degrees F to fully evaporate, which means that even at 300-degree oil temperatures, there can still be residual fuel that tends to reduce your oil's effective performance.

All of these are excellent reasons normal drain intervals are a good idea, even if you decide to step up to the more expensive synthetic oils. There are also synthetic blends offered by most major oil companies that are a composite mix of both synthetic and petroleum-based oils and are less expensive, but also reduce the oil's overall potential performance.

Track days on road courses are becoming increasingly popular with the Pro Touring crowd. Even a couple of laps of wide-open throttle use will rocket oil temperatures far above 300 degrees F if the engine is not equipped with an oil cooler.

Track days on road courses are becoming increasingly popular with the Pro Touring crowd. Even a couple of laps of wide-open throttle use will rocket oil temperatures far above 300 degrees F if the engine is not equipped with an oil cooler.

Thinner Is Better?

Besides the inherent high-pressure lubrication advantages in areas like the cam and lifter interface and piston rings to the cylinder wall that synthetics offer, there has been a move in the last few years to create lighter viscosity oils that can still deliver protection and temperature stability with thinner oils that are easier to pump. It's a generally accepted fact that thick oil tends to create higher oil pressures. The thicker or more viscous the fluid, the more power is required to push the lubricant throughout the engine.

The trick is to create an oil that requires less power to pump through the engine yet still delivers sufficient protection. Oil pressure is an indication of resistance to flow in the engine, so it makes sense that reducing the oil pressure (while maintaining sufficient flow to protect the internal components) will result in more power. Drag racers have been doing this for years with excellent results.

This is an oil cooler located in the nose of a Cobra replicar. The cooler is positioned directly in the path of fresh, cool air in an attempt to keep oil temperatures in line when running the car on a road course.

This is an oil cooler located in the nose of a Cobra replicar. The cooler is positioned directly in the path of fresh, cool air in an attempt to keep oil temperatures in line when running the car on a road course.

Farner showed us some Quaker State research that tested several different weights of synthetics to dig up some horsepower from this thin-oil theory. Quaker State actually tested five different multi-grade synthetics on a 300hp small-block Chevy, including a range of oils between 10W60 and an incredibly thin 0W10. While you might think that the thinnest oil would have the best shot at making the most power, the 0W20 turned out to be the best in terms of both peak power and best overall power. We're talking about minor power differences of around 8 hp between the 10W60 oil and the 0W20, which is still a great change based on how easy it was to make this power.

This test looked intriguing, so we decided to do our own testing with a much higher horsepower small-block. Our test "Mule" is Bill Mitchell's 454ci small-block Chevy that we spooled up on the dyno at Westech. For our test, we limited the testing to three different-weight oils starting with a petroleum-based 20W50, then to Quaker State's full synthetic 10W30, and finally to Quaker State's full synthetic 5W20.

Synthetics enjoy a significant advantage over petroleum-based oil in terms of high-pressure anti-wear characteristics such as the interface between the cam lobe and lifter. If you've ever handled synthetic oil, it even feels more slippery than conventional oil.

Synthetics enjoy a significant advantage over petroleum-based oil in terms of high-pressure anti-wear characteristics such as the interface between the cam lobe and lifter. If you've ever handled synthetic oil, it even feels more slippery than conventional oil.

During the testing, we noted that the 20W50 oil temperature seemed to remain much more stable during the testing. As we tested the thinner oils, each less viscous oil seemed to gain oil temperature much more quickly than its thicker cousins. We also saw an accompanying slight drop in oil pressure as we tested the thinner oils, which we expected. Once we assembled all the data, it appeared that the thinner 5W20 oil performed much better, but after averaging the data, compared to the thicker 20W50, the average power was only marginally better. Average power is probably the better way to look at this data, since the one 10hp gain at 5,000 rpm is not consistent with the other tests. Plus, this would even out had we tested each combination over 10 runs and averaged the numbers.

The focus of this exercise is that thinner oil will support a slight power gain and the only real cost is around $10 or $15 per oil change. But besides the potential power gain, there are significant advantages to using synthetic oil, especially if you plan on running your engine hard at the next track day. The engine you save just might be your own!

Test 1: We baselined the engine with a petroleum-based 20W50 oil. All testing kept the oil temperature between 190 and 200 degrees F.

Test 2:> We changed to Quake State 10W30, including the oil in the filter.

Test 3: Changed oil again, this time to Quaker State 5W20.

Dyno Results

RPM Test 1 Test 2 Test 3 Difference HP HP HP HP 3,000 288 289 288 - 3,500 343 344 345 + 2 4,000 408 410 409 + 1 4,500 476 476 476 - 5,000 522 526 532 + 10 5,500 549 551 555 + 6 6,000 561 567 562 + 1 Peak HP 572 570 569 - 3 Average HP 465 466 467