It was time to update and tune the suspension/tire combination on the ol' R/T. An assortment of outdated and original suspension parts were no longer assisting in consistent hookups. Here we are on a run testing the effectiveness of new rear QA1 shocks and Hoosier slicks.

It was time to update and tune the suspension/tire combination on the ol' R/T. An assortment of outdated and original suspension parts were no longer assisting in consistent hookups. Here we are on a run testing the effectiveness of new rear QA1 shocks and Hoosier slicks.

When we last tried to strip test our '67 R/T with its new Barton 493 wedge ("Long-Armed Wedge," June and July '03 issues), it was difficult to hook up on launch. The 60-foot times varied from 1.63 to 1.73 seconds, depending on how fast the accelerator was depressed (slowly walking it out worked best). We almost broke into the 10-second zone with a traction-limited 11.01 quarter-mile e.t. A few tenths were lost due to tire spin in the first 10-200 feet, and we finally realized it was time to update the old B-Body's suspension system. the Barton engine was out of the car for some "other workings," and we wanted to strip test a couple suspension components. We decided to install a Ray Barton-supplied 440 short-block, as well as the top end from our 493.

Springs And Things

Confident that the Coronet's chassis was solid and stiff enough due to a solid body and subframe connectors, the first step was to focus on the leaf springs. The original 426/440-type leaf springs with five leafs on each side-aided by the one half-leaf on the left side and the two half-leafs on the right-were no longer tough enough to handle the torque of the stroked wedge, so we ordered a set of custom replacement springs from Eaton Detroit Spring. These springs featured an extra leaf (now six) on each side to reduce spring wrap-up. After installation, the ride, handling, and traction (it didn't spin or go sideways as much punching it at 50 mph) was noticeably better on the backroads.

We'll gladly trade a stock, cushy ride for better hook at the track and firm handling. Time and money is well spent in preparing the rear suspension to exceed stock-type performance limitations. Eaton Detroit Spring custom-built us a stronger set (an extra leaf on each side for less spring wrap) of the 440/426 Hemi-type leaf springs. QA1 sent us a set of their ultra-high-quality adjustable shocks (PN TC1539P). After cleanup of all the suspension parts (except the new shocks) we used Eastwood's paint products.

We'll gladly trade a stock, cushy ride for better hook at the track and firm handling. Time and money is well spent in preparing the rear suspension to exceed stock-type performance limitations. Eaton Detroit Spring custom-built us a stronger set (an extra leaf on each side for less spring wrap) of the 440/426 Hemi-type leaf springs. QA1 sent us a set of their ultra-high-quality adjustable shocks (PN TC1539P). After cleanup of all the suspension parts (except the new shocks) we used Eastwood's paint products.

Shocking Facts

Further suspension tuning consisted of a trackside install of QA1's 12-way adjustable shocks. These shocks allowed the driver to switch between a softer "street" feel, and a help-plant-you-in-the-seat "strip" feel. We'll let you know what settings worked for us.

The antiquated shock setup on our Dodge was typical of the dual-purpose car built between the 60s and the 80s. Up front, weak standard-duty shocks were used for fast front-end rise to aid weight transfer to the rear tires. These wimpy front shocks were scary on the highway, with excessive dive and rise tendencies from the dips on the road. In other words, the R/T suffered with poor road-holding ability.

Out back, air shocks supported an even stance, with 40 psi in each shock when driven on the street. For the track, 10 psi in the left shock and 20 psi in the right shock provided a good launch-that is, until they faced the torque monster. The compression (bump) and extension rates (damping force) of the outdated air shocks hurt both the e.t.'s and the handling.

With 12 adjustment settings, the QA1s offer a wide range of bump and rebound control. These adjustable wonders lower e.t.'s, aid in high-speed stability, and reduce body lean by leaps and bounds.

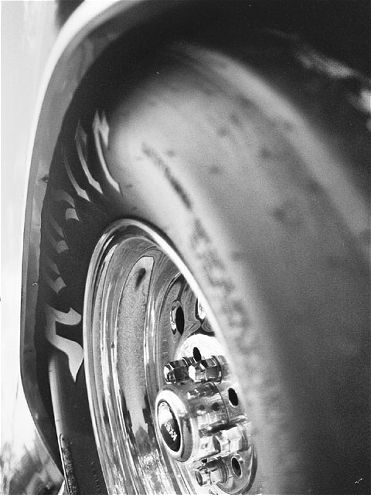

Once we trial fitted the 30x9R-15 Hoosier slicks on the 15x8 1/2-inch rims, the sidewalls rubbed the inner and outer section of the wheelhouse. A little creative modifying to stretch the wheelhouse to within 1/4 inch of the quarter-panel was all that was required. Before the stretch-job began, the wheelhouse was 1 1/2 inches from the quarter-panel. Instead of rolling the wheel lip and molding, it was cut back 1/2 inch for tire clearance.

Once we trial fitted the 30x9R-15 Hoosier slicks on the 15x8 1/2-inch rims, the sidewalls rubbed the inner and outer section of the wheelhouse. A little creative modifying to stretch the wheelhouse to within 1/4 inch of the quarter-panel was all that was required. Before the stretch-job began, the wheelhouse was 1 1/2 inches from the quarter-panel. Instead of rolling the wheel lip and molding, it was cut back 1/2 inch for tire clearance.

Hook And Roll

Most of us Moparites realize that various wheel and tire weights can make a difference in street or strip performance. The sprung and unsprung weight of different wheel and tire combos (heavy to light, light to heavy) change how a suspension reacts. That's a good reason to have shocks that can be adjusted to meet the changes in suspension reaction.

Lighter wheels and tires have been providing lower e.t.'s and more mph for many years. We've been running heavy, stock wheels for too long. To perform this test of springs, shocks, wheels, and tires, we needed to gather up the appropriate parts. We had a set 15x8 1/2-inch Weld Draglites left over from a previous car, as well as a swap-meet set of 15x7-inch Centerline Auto Drags, and a couple15x7 cop-car wheels that would handle an old-versus-new 28x9 Hoosier slick test. To further combat our traction woes, Hoosier's new 30x9R-15 radial slicks (28s are not available yet) will be put to the test. These radial-design tires offer less rolling resistance, along with the advantage of a larger footprint. The radial slicks were mounted on the 15x8 1/2 Weld Draglites (the wider rim spreads the tread more evenly for better tire-contact patch).

From this view, it's obvious how tight the fit is for the 30-inch slick. Notice the cutting work done to the wheel lip and molding for clearance. The '66-'67 B-Body has the smallest wheelwells of all the B-Bodies, with the exception of the '65 Coronet. This type of backyard butchery could help some A-Body gearheads fit a 28x9 tire on a 7-inch rim with the proper backspacing.

From this view, it's obvious how tight the fit is for the 30-inch slick. Notice the cutting work done to the wheel lip and molding for clearance. The '66-'67 B-Body has the smallest wheelwells of all the B-Bodies, with the exception of the '65 Coronet. This type of backyard butchery could help some A-Body gearheads fit a 28x9 tire on a 7-inch rim with the proper backspacing.

Out on the street and at the shows, the factory chrome Road Wheels and Coker Classic Redline radials maintained that '60s look. The redline radials also provide a better ride and handling over bias-ply tires. For years, we have wanted to strip test a set of front skinnies (lightweight front wheels and tires), so we scored a set of 3 1/2x15-inch Weld Draglites at the Englishtown fall swap meet. Hoosier provided us with a set of their lightweight, low rolling resistant front runners (26x4.5-15, PN 18105). Now we were fully armed, ready, and waiting for our test day at E-Town.

It was October and the track would be closing soon for the winter. [Oh, I miss those days. -Ed.]

Traction Reaction

Our goal was to show how easy it is to improve the hook at the track, through simple bolt-ons and adjustments. Our test day was a windy fall day at the famous E-Town facility. For a baseline, the well-used 28x9 Hoosier slicks mounted on the cop-car wheels were placed on the R/T. Air-shock pressure was set, the pinion snubber was adjusted, and the front sway bar was disconnected. On our first pass, the R/T made its quickest 60-foot time ever with a 1.61. Thanks to the new leaf springs, a quick stomp on the gas pedal was now possible. A backup run produced an identical 60-foot with an 11.21 e.t. Now, consistent bite was established.

Here the combatants wait for their strip brawl. At the weigh-in, the 15x7 cop wheel with the 28x9 slick was the heaviest at 42 pounds. The 15x8 1/2 Weld with the 30x9 radial registered 40 pounds, while the 15x7 Centerline with the 28x9 slick was the lightest at 34 pounds. The 30x9 radials are normally worth a tenth over the same size bias-ply slick, but they would have to run against the 28s in this fight. We baseline tested the R/T with the new leaf springs and the old cop wheels and worn-down 28-inch slicks. The new springs were good for additional bite, along with consistent and reduced 60-foot e.t.'s. The Centerlines with fresh 28-inch slicks were up next, and were equal in performance of the shredded slicks with identical 1.61 60-foot times-proof that the Hoosier tires work to the last race. We suspected the old air shocks were not firm enough to help plant the lighter wheel/tire combination (less unsprung weight) to the track.

Here the combatants wait for their strip brawl. At the weigh-in, the 15x7 cop wheel with the 28x9 slick was the heaviest at 42 pounds. The 15x8 1/2 Weld with the 30x9 radial registered 40 pounds, while the 15x7 Centerline with the 28x9 slick was the lightest at 34 pounds. The 30x9 radials are normally worth a tenth over the same size bias-ply slick, but they would have to run against the 28s in this fight. We baseline tested the R/T with the new leaf springs and the old cop wheels and worn-down 28-inch slicks. The new springs were good for additional bite, along with consistent and reduced 60-foot e.t.'s. The Centerlines with fresh 28-inch slicks were up next, and were equal in performance of the shredded slicks with identical 1.61 60-foot times-proof that the Hoosier tires work to the last race. We suspected the old air shocks were not firm enough to help plant the lighter wheel/tire combination (less unsprung weight) to the track.

Next, the five-year-old 28x9 Hoosiers were swapped for a set of the same size meats on the lighter Centerline rims. After the swap, we were still spinning slightly (hazing) and thought the new rubber would have added grip. After four passes-two back to back and two with a half-hour cooldown-the ol' Dodge ran four 1.61 60-foots, with a pair of 11.20s and 11.21s. We definitely needed new sneakers-the tread wear indicators were hardly visible on the old slicks!

We didn't realize the added traction from the new slicks and lighter wheels reduced sprung weight. Lighter wheels make it easier for a tire to unload and lose surface contact. We were sure a quick change to the QA1 rear shocks would help plant the tires. The air shocks were tossed, and we set our initial shock setting on the QA1s knob three clicks clockwise. Right out of the hole, the scoreboard read a 1.58 60-foot. We were on a good pass and turned an 11.18 e.t. A hot-lap backup pass produced an identical 1.58 60-foot, but at a slower 11.19 e.t.

After the usual half-hour cooldown, the adjustment knobs were turned three more clicks for additional shock stiffness. It worked-we hooked up with a 1.56 60-foot and an 11.16 quarter-mile e.t. A half-hour-later a backup run showed us dead-nuts-consistent traction with another 1.56 60-foot. We wanted to try a few more clicks, but were running out of track time.

We moved to the front shocks and set them at zero to retain the worn-out, old-school feature (easy to extend, hard to compress). Unfortunately, we didn't realize any gains in e.t. The old front shocks were trick units (easy to compress and extend), but they were dangerous on the road (excessive dive, rise, and body lean). For the ride home, we set the adjustment at six clicks (compression firmness doesn't change; extension stiffens with each increase in the adjustment) and the Coronet never held the road better in its 25 years of ownership.

Up front, we were anxious to try out the new set of front skinnies. The lightweight wheel and tire combo weighed 58 pounds less than the Road Wheels with redlines. We added 8 gallons of pump gas in an attempt to keep the test weight fair. The reduced rotational weight and rolling resistance scored us a similar 60-foot time, but a much quicker 11.06 at 122.08 mph. Trap speed increased by 1.25 mph from the previous best of the day. High-speed stability improved thanks to the Hoosier front-runners and QA1 shocks.

We've been hearing from the stock eliminator and bracket racers about the new radial slicks lowering e.t.'s and increasing mph. On the first run with the radial slicks, we saw an improvement with a 1.55 60-foot and an 11.01 e.t. at 122.57 mph. That's an impressive gain considering we lost the effective gear ratio going to the taller tires. The engine speed through the traps was 300 rpm lower at 6,000. A hot lap returned an 11.02 at 122.39 mph. Man, that's cooking with a pump-gas 440.

Slick Tips

oosier recommends running 4-5 psi more inflation pressure in the radials than for the setting on bias-ply slicks. Since there was 14 psi in the bias plys, 18 psi was put in the radials. All the slicks tested received an 8-second burnout before launch (it was in the low 50s all day). On days with warmer ambient air and track temps, a 4-6 second burnout is sufficient to warm the tires.

To extend the life of your slicks, proper storage includes an environment without ultraviolet light, electric motors, and a temperature change of no more than 30 degrees. The 5-year-old Hoosiers have lasted more than 150 runs of strip testing. Try to do the shortest burnout required that will allow the tire to hook, and you'll be surprised at how much longer the slicks last.

Conclusion

In nearly 10 years of strip testing and bracket racing, Hoosier slicks have provided us with consistent bite. The radial slicks and front-runners proved less rolling resistance will reduce friction, parasitic drag, and e.t's. Many racing Mopar owners enjoy the big difference that the right shocks make in the performance of their cars. QA1's easy-to-reach adjustment dial gives you the opportunity to have the best of both worlds. They assisted the R/T in becoming a better road and track machine.

Dragstrip Results