| Nissan 350Z VQ35DE Engine Build - NA Power Building

| Nissan 350Z VQ35DE Engine Build - NA Power Building

It’s been well over a year since we did a street cam test on the VQ35 to show you the kind of power that a set of extremely streetable cams can make with an uncorked engine. Now we’ve stepped into the race car realm and individually tested a bunch of wild parts, one at a time, to see what works, what doesn’t, and where the bottlenecks are.

| Jim Wolf’s GA cams bumped power output from 292 whp to 326 whp.

| Jim Wolf’s GA cams bumped power output from 292 whp to 326 whp.

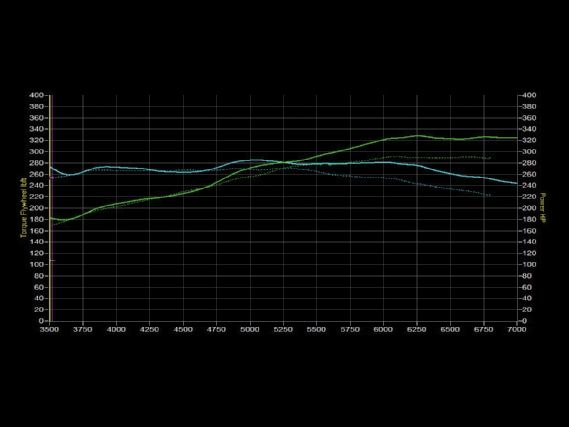

If you remember the last article we used my personal 350Z race car for testing, and with our custom, long-tube, stepped headers and large intake manifold, stock cams produced 272 whp. Our aftermarket Jim Wolf Technology cams got us up to right around 292 whp. A stock non-rev-up 350Z/G35 will usually put down 215 to 220 whp, so that gives you an idea of the gains we had already made. Would you believe me if I told you by the end of this article we will have gained another 100 whp?

The first step of this process was to install more aggressive cams with aftermarket valvesprings designed specifically for racing. The cams in question were Jim Wolf’s GA cams designed for Grand Am’s Koni Challenge series in 2003 or so. With 300 degrees of duration, these cams don’t idle all too well and won’t run very smoothly below 2,000 rpm, but they make power. From 292 whp, the power shot up to 326 whp with the larger race cams, and thanks to the VQ’s variable intake cam timing, they increased power everywhere from 3,500 rpm upward.

| Rev-up versus non-rev-up lower intake manifold comparison. Clearly the gains are only worth it if you are going to keep the rpm well above 6,500 rpm

| Rev-up versus non-rev-up lower intake manifold comparison. Clearly the gains are only worth it if you are going to keep the rpm well above 6,500 rpm

The next step was to build a bottom end that could handle higher rpm reliably, since we know that without rpm, we cannot make horsepower. We also want some more compression to work with high-duration, high-overlap cams. JE crafted a custom set of 12:1-compression pistons, and Eagle Rods supplied its tried-and-tested rods that are known to handle gobs of turbo power, so this NA application should be a breeze. Surprisingly, the higher compression on its own did not gain any power at all. In fact, the dyno graph looked exactly the same as the stock engine’s. I found this incredibly strange, and many engine builders I talked to explained that it didn’t make any sense.

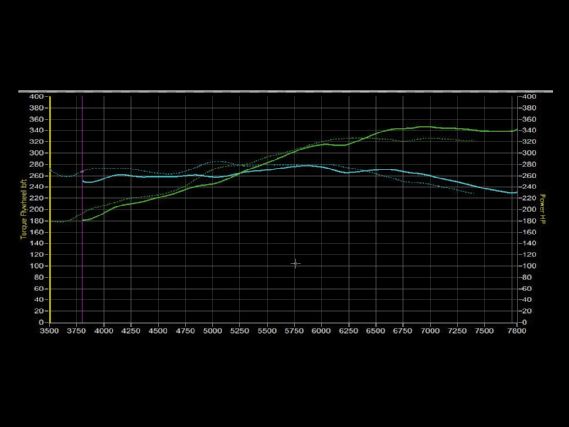

Determined to make at least 100 whp per liter, we pressed forward and tried the rev-up intake manifold from the ’06 350Z, which has slightly shorter runners. There were some power gains to be found (336 whp to be exact) at the loss of midrange torque. This was a setup for high-speed tracks only.

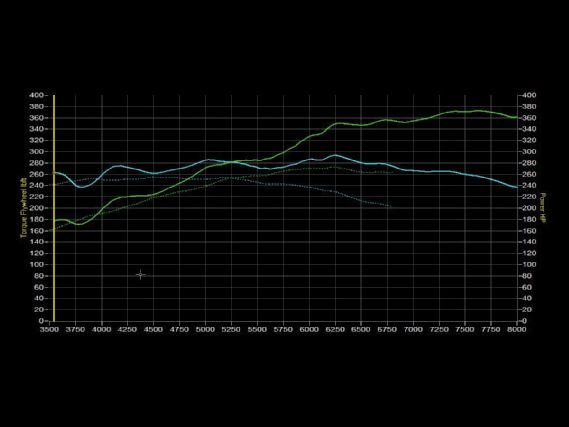

I got on the phone with Jim Wolf Technology who advised me of an even larger cam that would breathe better up top, as it has substantially more lift. JWT sent its C10 and C9 cams—the C10 is so big that the company doesn’t even advertise it for sale. The C10 has 300 degrees of duration, and the C9 has 287 degrees. But what sets these cams apart from the previous GA cams is that they have a ridiculous 13 mm of lift—almost 1.5 mm more than any other aftermarket cams. We installed the C10 on the intake and the C9 on the exhaust, as JWT suggested that the C10 on both intake and exhaust might cost us too much midrange power. Well, the combination of shorter intake and larger cams got us up to 346 whp, but it still wasn’t 100 whp per liter. We later tried the C10 on the exhaust and found that the engine didn’t lose any bottom-end power but lost some horsepower in the last 1,000 rpm. Clark at JWT suggested that the exhaust was likely outflowing the intake with the C10 exhaust cam. By putting the C9 back in, we brought the mass flow balance back into the engine’s sweet spot, and despite using a smaller cam, the engine makes more top-end power. I am never short of amazed at the kind of feedback and knowledge Jim Wolf has when it comes to cam development and engine building. The company has been a huge resource for us as we continue to try and build more and more power.

So what was next? Well, the heads were still stock, and while the VQ has a pretty efficient head design from the factory, there is always something to be gained from porting and multi-angle valve jobs. Gord Bush Performance performed a multi-angle valve job, deshrouded the valves to allow for more airflow at low valve lifts, and opened up the bowls of the ports, where the airflow is most critical.

Gord flow-tested the heads before and after the porting so we could quantify the flow gains. We saw roughly a 10 percent increase in flow, which should equate to a similar percentage of increased power, assuming no other bottlenecks (there are always other bottlenecks, don’t be fooled). After reassembling the engine and breaking it in, we went for the power pulls. What did we see? The exact same amount of power as before—just like when we built the block and gained nothing.

We realized that at this point the head wasn’t a restriction and that until we found the real bottleneck, wouldn’t see the gains from the head porting. So what did we do? We popped the top.

What is popping the top, you ask? Well, on a VQ35, the upper intake plenum is bolted to the lower intake plenum. When you pop the top, you remove the top plenum cover in the middle of a dyno pull to see how much power the intake runners would make if they were breathing in fresh air, without having to draw through the confines of the upper plenum cover, throttle-body, and piping. Now keep in mind that we already have a custom upper intake manifold with a 90mm throttle-body. The engine went full lean and we aborted the dyno pull. This was great news, as the engine is tuned by throttle position only. If it’s going lean, it must be flowing more air. So after adding a ton more fuel and popping the top again, the car put down 360 whp.

The next logical step was to figure out a new intake for the car. Now a single throttle-body with drive by wire is great, but ITBs are ridiculously awesome. They have a lot of advantages, too. First of all, with such a large, aggressive cam, the engine doesn’t create very much vacuum. And with a large plenum like the one we had previously, the airflow through the plenum is horrible—the engine is constantly surging and will not run below 1,500 rpm. The throttle response is very slow because any throttle change required first filling the plenum with air before that air went into the cylinders.

We contacted Jenvey, and its ITB kit is a relatively simple affair considering the complexity of the task at hand. Jenvey has taken care of the complete linkage, manifolding to the heads, and fuel rails. All that is required is a custom throttle cable, injectors, and air filtration. The fit and finish of the kit were pretty incredible: The holes for all the hardware were machined to tolerances tighter than anything I’ve ever seen, and surprisingly, everything fit together perfectly, which is amazing considering it had to be bolted to two separate heads that were also bolted to a block, all of which were originally machined with some level of tolerance at Nissan.

| Switching over to an ITB setup versus a plenum intake manifold netted a peak of 372 whp.

| Switching over to an ITB setup versus a plenum intake manifold netted a peak of 372 whp.

It worked out well that we had to change the injectors, as the factory injectors were maxed out anyhow (we had to raise the fuel pressure to 85 psi during the 360-whp run). Injector Dynamics are always my injectors of choice, and every car I’ve built with them has run like a dream, each and every time. The 725cc injectors were more than enough for an NA application, and with the PnP connectors, it was a breeze finishing the fuel system. A few custom lines later and we were ready to start the engine.

After some tuning on the dyno, I knew the engine was going to make real power when a pull to only 7,000 rpm showed in excess of 355 whp. At the end of the tuning session, I had multiple consistent 370-plus-wheel-horsepower pulls, the highest being 372 whp.

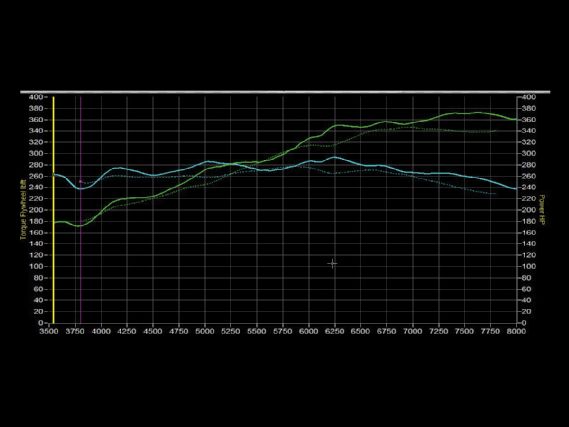

Likely the most amazing thing about this entire process is to take where we are now and compare it with an entirely stock non-rev-up dyno. You can observe that from as low as 3,500 rpm this engine makes more torque, despite being set up to run at high rpm.

| This is what a 100-whp gain looks like versus our stock VQ engine.

| This is what a 100-whp gain looks like versus our stock VQ engine.

This step-by-step process is what has allowed us to measure and quantify each part, to ensure that everything we install on the engine makes power, and that we’re going in the right direction. It has helped us realize where the bottlenecks are and has shown that when you play with areas that are not your largest bottleneck, chances are you will not see very substantial differences. However, that doesn’t mean those improvements won’t show themselves when you open up the actual bottleneck in question. We’ve also learned to appreciate the narrow window within which we work. Bigger isn’t always better, and matching pistons, cams, heads, header, and intake are becoming more and more crucial as we progress beyond 100 whp per liter on this size engine. The more power we make, the more important it is to very carefully analyze each change individually, because it’s so easy for it to all go wrong and for the engine to produce less power.

| Nissan 350Z VQ35DE Engine Build - NA Power Building

| Nissan 350Z VQ35DE Engine Build - NA Power Building

The next steps for this engine are shorter intake trumpets, adjusting the exhaust cam timing with Jim Wolf’s newly released adjustable exhaust cam sprockets, and possibly shortening the headers to see if the engine can continue to make more power as rpm increases, hopefully toward 9,000 rpm. It certainly won’t last very long, but it will be awesome. The VQ is known to have crank and oil pump issues at the rpm we’re at, so that’s an entirely separate challenge. Four hundred wheel horsepower isn’t all that unrealistic, as long as we can build a bottom end that will hold together.