Hardcore rotary fans are passionate to say the least and some may say cultist in their obsession with all things Wankel, but comparing them to zombies may be a bit harsh. Rotorheads are a lively bunch with an appreciation of outside-the-box thinking and leading edge technology; what’s not to like?

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

The Mazda rotary engine is the ultimate underdog, belting out big league power numbers from a scant 80 inches of displacement. At 350 cubic inches, a small-block Chevy is more than four times bigger than a 13B. To put things in perspective, the 1993 Mazda RX-7’s 1.3-liter 13B pumps out 255 horsepower or 196 horsepower per liter. Conversely, the ’93 C4 Corvette flagship, the ZR-1, produced 405 horses from its 5.7-liter LT5 V8 or only 71 horsepower per liter.

It should also be noted that Mazda is celebrating the 20th anniversary of its overall victory at the legendary 24 Hours of Le Mans in 1991. Mazda is the only Japanese manufacturer to ever take overall victory at Circuit De La Sarthe, its weapon of choice was the Mazda 787B powered by a special four-rotor R26B rotary powerplant.

Rotors vs. Pistons A rotary engine generates its power in a decidedly unique fashion. Engines are all about compressing air and burning fuel. Pistons in a conventional reciprocating internal combustion engine are moved up and down in a cylinder via connecting rods and a crankshaft. They operate in four cycles: intake, compression, ignition and exhaust with the piston’s movement creating the compression/combustion in the cylinder head at or near TDC.

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

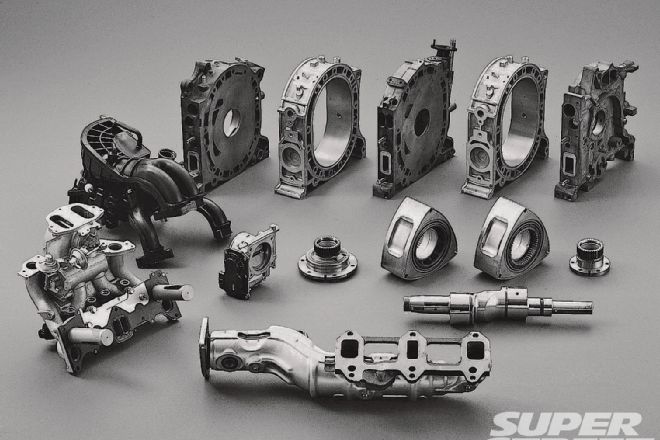

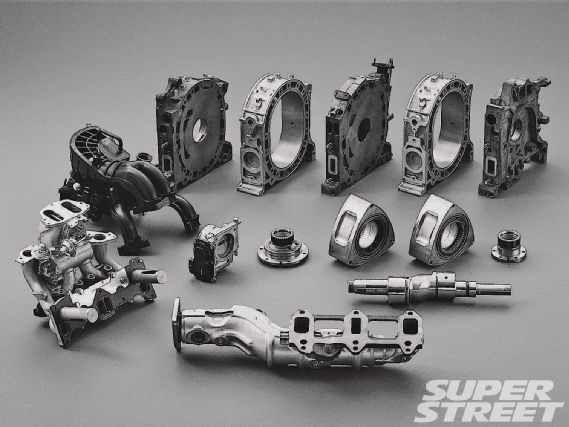

Sometimes called a Wankel rotary in reference to its inventor, Dr. Felix Wankel, the rotary engine consists of two rotors, two rotor housings, three support housings (front, intermediate and rear side), stationary gears, an output shaft and bearings. Where a piston engine’s combustion chamber is fixed, the combustion chamber in a rotary powerplant spins around inside the engine.

Understanding The Beast

The rotors consist of convex triangular components (familiar to most enthusiasts) with gear teeth at their center. Pockets that serve as combustion areas are carved on the outside edges of the rotor. The edges where the convex faces meet are fitted with apex seals that seal in the combustion chamber in much the same way a head gasket works in a piston engine.

|

“Rotary combustion chamber”

|

“Rotary combustion chamber”

Each rotor spins in a housing that has spark plug, intake and exhaust accommodations machined into it. The inside surface of the housing is an epitrochoid shape, an oval shape with a slight hourglass effect in the mid-section.

This unique shape allows the apex seals to maintain constant contact with the surface as the rotor spins on the output shaft ensuring uncompromised combustion.

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

As the rotor turns in the engine, the combustion pocket experiences the four cycles of combustion. The output shaft is the equivalent of a crankshaft in a piston design and its off-center (eccentric) lobes provide the leverage needed to spin the shaft, which generates torque that is sent to the drivetrain via a flywheel. The front, intermediate and rear side housings contain the gears and bearings to support and lubricate the output shaft.

Porting Gateway To Rotary Power

Porting the housing on a rotary engine is akin to cylinder head work on a piston engine. It addresses the amount of air moving through the engine, which ultimately provides the potential to burn more fuel and make more power. But there are compromises at work, as more aggressive porting can have unwanted effects on drivability and fuel efficiency among other things. Rotary builders use four different types of porting.

Street Port

A street or “mild” port cleans up the port but only slightly alters its shape. This porting job also adds a lip at the top of the port for enhanced flow. This method bumps top-end power without changing the engine’s operating characteristics.

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

Mild/Extended Port

As the name indicates this method takes a mild porting job and extends the port at the bottom edge. This enlarges the port substantially, resulting in dramatic increases in flow and should be used on engines with intake and exhaust mods designed to handle increased flow. This is a good method for street cars because overall drivability is retained with little chance of the engine exhibiting that signature lumpy rotary idle.

Peripheral Port

This is no holds barred, anything for power warfare. Shaping the existing port is not even a consideration as a peripheral port job ditches the die grinder; instead the ports are filled and new, round ports are added. Peripheral port engines are really loud, incredibly fuel thirsty, idle at 2,000 rpm and make their power way up in the rev range in a very narrow powerband window, making them race-only propositions illogical to even consider running on the street. The peripheral port engine also has a much shorter life cycle than more moderately ported powerplants.

Bridge Port

Things get extreme here, as a new, separate eyebrow groove is cut into the housing adjacent to the original port. The material between the openings (the bridge) serves to ensure proper sealing. This mod pumps up the power on the top end and allows a much higher redline. This path takes all the smoothness of normal rotary power delivery out of the equation and tosses it to the curb, turning the engine into a raspy sounding brute both under duress at WOT and at idle.

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

Port Power Expectation

Racing Beat is a name synonymous with rotary power and we contacted the Anaheim, California shop’s owner, Jim Mederer, to get his input on the intricacies of the rotary engine. Jim says intake porting selection is usually determined either by racing rules or by the owner’s perception of the best port style for his application. “If power is the only object, go peripheral, even for boosted applications,” says Jim. “Use bridge porting only if your rules require it because bridge ports make less power than peripheral and has no compensating benefits. However, never use restrictive muffling on either of these ports as the backpressure will force the exhaust gasses to back-up into the intake charge and kill engine power. Street porting and stock porting are okay for muffled applications.”

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

“For those considering the RX-8 Renesis engine, which has side exhaust ports instead of the peripheral exhaust ports in previous iterations, there is no question that the stock engine makes good power, about 215 horsepower. That stock power can be raised to 245-plus with careful street porting and a number of other improvements, but that is about the limit. This engine has restrictive exhaust porting (effectively like a muffler on a peripheral exhaust engine), so don’t try bridge or peripheral porting on it.”

We asked Jim what the reasonable maximum power expectations for each type of intake porting would be and he fired back—peripheral intake port 300-plus horsepower, bridge intake port 270-plus horsepower, street intake port 220-plus horsepower. These are naturally-aspirated numbers.

“The rotary experience is quite attainable. There are plenty of healthy wankels out there for the taking.”

Basic Bolt-ons/ Troubleshooting

What about quick and easy power mods? The RX-8 is a tough nut to crack with intake and exhaust system mods producing only modest 7-to 10-whp gains. A full, cat-back exhaust accounts for only 3-4 horsepower, which is a testament to how restrictive the Renesis exhaust ports are.

Thanks to its factory twin turbo engine, the FD RX-7 is a much more willing power partner. The same basic intake and exhaust components net a 14- to 16-whp bump in output. These mods also improve much needed torque to the tune of 30 lb-ft.

The RX-7 is notoriously hot-headed. Its cooling system is the root of many of its problems. “We never promoted large power increases in the FD at Racing Beat because, in our opinion, it was marginal in cooling and other areas in stock trim and we didn’t want to answer the phone calls when things went bad,” says Jim. “The FD (and RX-8) changed from mechanically driven fans to electric (for many reasons) and in doing so, weakened the cooling system. On top of that, the RX-7 didn’t pass enough air through the radiator and then to top it all off it wasn’t able to move air out of the engine compartment—a classic case of trying to put “two pounds in a one pound box.”

One of the classic maladies from this lack of cooling beyond overheating and mild boost-up engine meltdowns is vacuum line failure. If your RX-7 feels sluggish on the road cracks in the vacuum lines, especially those located under the intake manifold, may be robbing you of power and drivability. Replace the lot with more heat resistant silicone, not OE rubber hoses.

Strengths/Weaknesses/Quirks

The rotary is perceived as being over-sensitive, especially when boost is applied. The center of this sensitivity has been the apex seal and the original wide carbon apex seals are particularly at risk. But design improvements in rotor, housing and apex seals (both OE and aftermarket) have dramatically enhanced reliability so later engines are better. While many scenarios can cause an apex seal to fail, Jim relates that detonation and high temperatures in either the rotor housing (water cooling) or in the rotor (oil cooling) are usually to blame. Competent tuning is also a critical variable. Those still in doubt about the rotaries durability need only look to motorsports. Rotaries have been battle tested on the track in endurance racing and at the Bonneville Salt Flats where durability is the key to success.

|

Rotor Apocalypse - Tech

|

Rotor Apocalypse - Tech

“Perhaps the greatest strength of the rotary is that you can spend quite a bit of time on the dyno searching for power and as long as you hold temperatures, pressures and ignition timing where they belong, the engine remains stable and power does not fall with age,” says Jim. “This is at the heart of why rotaries do so well in long distance races. However, the corollary weakness is that, if temperatures, pressures and ignition timing are NOT correct disaster will ensue shortly.”

“As for quirks, perhaps the most notable is that you cannot use an oxygen sensor as the primary method of tuning the mixture—if you want peak power. The reason is that, unlike reciprocating engines, if you map a rotary at, say, 12.5:1 air/fuel ratio (or any other guideline number) the engine will be lean in some places and rich in others. For peak power, the engine may need anywhere from 10.8:1 to 13.4:1, depending on porting, tuned intake lengths, rpm range and a host of other factors.”

Another quirkish tendency is how the rotary reacts to timing. “From a timing standpoint it is important to do all mixture and tuned intake length adjustments with the ignition timing slightly retarded,” says Jim. “This means about 22 degrees BTDC maximum for stock and street port engines, 19 degrees BTDC maximum for Bridge and Peripheral intake port engines, and 10 degrees BTDC maximum for highly boosted engines. This assumes you are firing leading and trailing ignitions at the same time, which I recommend, and no vacuum advance. After all other tuning efforts are completed; start advancing the timing, preferably in steps of 1/2 degree. At the first sign that additional timing isn’t giving more power, STOP and back up! Further advance can be harmful to the engine.”

The rotary experience is quite attainable. Be it an old-school RX-2 or a rotary swapped Datsun 510, a first-gen RX-7 (1979 to ‘85) or FC or FD vintage RX-7s there are plenty of healthy Wankels out there for the taking with prices running the gamut from a few hundred bucks to $10,000 to $15,000. Damn the zombies; dare to be different because the pay-off can be huge. Become a rotor-head…TODAY!

Source:

Racing Beat, racingbeat.com, 714.779.8677