Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

“Is it worth buying a Rubicon edition?” We hear that question routinely. Out of the box, it’s hard to beat the Wrangler Rubicon. While the first-edition Rubicon (’03-’06) was jam-packed with off-road features, Jeep took things up a notch with the ’07 model year. In addition to front and rear selectable differential lockers, mud-terrain tires, and a 4:1 transfer case ratio, the JK Rubicon platforms now came standard with an electric push-button sway-bar disconnect and Next Generation Dana 44 axles.

Gone was the weaker low-pinion Dana 44 front axle from the TJ Rubicon, and in its place a far better high-pinion Next Gen (NG) Dana 44. The reason the high-pinion differential is significant has to do not only with raising the front driveline out of harm’s way, but more importantly, it allows the pinion to power on the stronger drive-side of the ring gear when going forward. An improved unit bearing design, 1350-equipped axleshaft U-joints, and a vastly improved steering configuration also set the NG Dana 44 axle apart.

Out back, the Rubicon NG Dana 44 remained a low-pinion design but received a bump in ring gear size to 8.8 inches. The axle spline count also moved up from 30 to 32 (Rubicons only). Sure, there are still some things not-so-great about the Next Gen 44s, but for the most part, they are a tremendous upgrade over the TJ Rubicon 44s of old.

RCV Performance is known mostly for its custom CV-joints, but the company also offers direct-replacement 300M rear ’shafts. For those unfamiliar, 300M is 4340 chromoly with an extra helping of vanadium, silicon, carbon, and manganese. After being thoroughly hardened, 300M gains around 2.33 times the tensile strength over a standard (stock) 1040 carbon-steel axleshaft.

RCV Performance is known mostly for its custom CV-joints, but the company also offers direct-replacement 300M rear ’shafts. For those unfamiliar, 300M is 4340 chromoly with an extra helping of vanadium, silicon, carbon, and manganese. After being thoroughly hardened, 300M gains around 2.33 times the tensile strength over a standard (stock) 1040 carbon-steel axleshaft.

When we picked up our ’07 Wrangler Unlimited Rubicon, we had no doubts how we wanted to build it. This isn’t our first rodeo with a JK (or a Rubicon for that matter). With 37-inch tall tires on the horizon, we knew exactly where the weak points of the NG 44 axles would be. While we have other upgrades in store for the axles, for now, we’ll show you by far the easiest and most significant way you can increase the strength of the JK Rubicon 44 axles.

These bolt-in upgrades are designed to place your JK’s NG Dana 44 axles into the Dana 60 strength realm. This is thanks to a very unique and high-strength set of axleshafts made by RCV Performance. Well known for its heavy-duty CV axleshafts, RCV Performance also offers bolt-in 300M rear axleshafts for the Jeep Wrangler JK.

We’ve shown you the highlights of the made-in-the-USA RCV CV axleshafts in the past, and with years of trouble-free use from our previous joints, it’s no wonder why we are going with the limited-lifetime-warranty axles again. For those unfamiliar with the advantages of the RCV CV joints, the concept and execution is very simple and effective: When a traditional axleshaft U-joint is set at an angle (wheels turned), it not only loses strength but changes velocity as it rotates. Both of these are factors in why front axleshafts fail and can ultimately wipe out your entire frontend on the trail.

The RCV CV joint retains strength throughout the entire steering range. Using the heavy-duty six-ball configuration means that the joint will always turn at the same speed (hence the constant velocity, or CV, namesake). This isn’t your neighbor’s run-of-the-mill CV axle. In fact, RCV has tested the bolt-in 44 ’shafts and found they easily rival (and out-last at a 40-degree angle) a U-jointed 35-spline Dana 60 axleshaft.

Essentially, for less than a quarter of what it would cost to swap in a Dana 60 to your JK, you are getting Dana 60 axleshaft strength. Outside of a 35mm socket and slide hammer, no specialty tools are needed to install the front or rear ’shafts. The JK’s Rubicon lockers have proved over the years that, in most cases, they do an adequate job of handling 37-inch-tall tires under the even more portly Unlimited platforms. With RCV ’shafts, we are simply ensuring that the rest of the axle’s hard parts are up to the task.

RCV offers Rubicon (32-spline) and non-Rubicon (30-spline) rear axleshafts. The ’shafts are dual-drilled with the JK’s 5-on-5 bolt pattern, in addition to a 5-on-51⁄2 bolt pattern.

RCV offers Rubicon (32-spline) and non-Rubicon (30-spline) rear axleshafts. The ’shafts are dual-drilled with the JK’s 5-on-5 bolt pattern, in addition to a 5-on-51⁄2 bolt pattern.

New bearings, backing plates, and tone rings mean the rear ’shafts are a simple bolt-in upgrade. For Rubicon models, the ’shafts are unequal lengths, with the shorter one installing on the driver side.

New bearings, backing plates, and tone rings mean the rear ’shafts are a simple bolt-in upgrade. For Rubicon models, the ’shafts are unequal lengths, with the shorter one installing on the driver side.

You’ll need to remove the brake calipers, rotors, and caliper brackets to access the axleshaft hardware. Four nuts connected to studs on the backing plate are what secure the ’shaft to the axlehousing. It’s best to use a slide hammer to remove the assembly from the housing.

You’ll need to remove the brake calipers, rotors, and caliper brackets to access the axleshaft hardware. Four nuts connected to studs on the backing plate are what secure the ’shaft to the axlehousing. It’s best to use a slide hammer to remove the assembly from the housing.

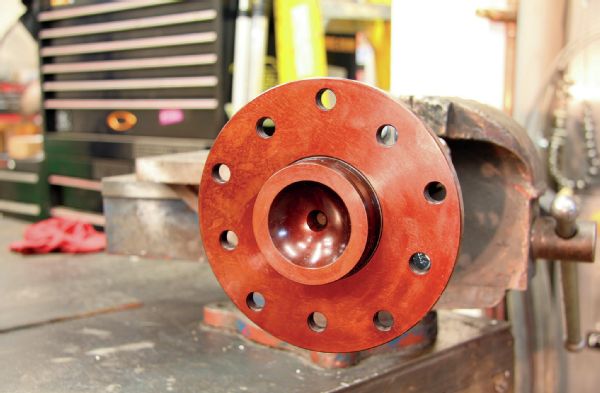

A massive billet steel bell, hardened metal inner race, and a six-ball bearing cage are the core internals of the RCV CV-joint. While it may look like other CV-joints, it’s not. To compare the company’s CV ’shaft to a stock ’shaft, RCV used an axle testing jig and tested both at a 40-degree angle. At 3,872 lb-ft, the U-jointed ’shaft failed. By comparison, the axleshaft itself, not the CV, snapped on the RCV at 7,604 lb-ft. Did we mention RCV has a “you break it, we replace it warranty”?

A massive billet steel bell, hardened metal inner race, and a six-ball bearing cage are the core internals of the RCV CV-joint. While it may look like other CV-joints, it’s not. To compare the company’s CV ’shaft to a stock ’shaft, RCV used an axle testing jig and tested both at a 40-degree angle. At 3,872 lb-ft, the U-jointed ’shaft failed. By comparison, the axleshaft itself, not the CV, snapped on the RCV at 7,604 lb-ft. Did we mention RCV has a “you break it, we replace it warranty”?

You’ll install the boot between the steering knuckle before you slide the ’shaft through. The company provides a special seating tool that allows you to properly set the boot on the bell. Be sure to grease the end of the ’shafts splines and make sure it’s lined up properly. Never force the ’shaft in. The JK front axle seals are not the best, and it doesn’t take much to rip one and end up with a gear oil leak.

You’ll install the boot between the steering knuckle before you slide the ’shaft through. The company provides a special seating tool that allows you to properly set the boot on the bell. Be sure to grease the end of the ’shafts splines and make sure it’s lined up properly. Never force the ’shaft in. The JK front axle seals are not the best, and it doesn’t take much to rip one and end up with a gear oil leak.

We had a feeling the previous owner of our Rubicon didn’t perform much maintenance on the Jeep. We had ordered some new rotors and pads from Omix-ADA ahead of time, as a quick inspection revealed the original components were heavily worn. We knew our rear pads were pretty low but were surprised to see just how gone they were.

We had a feeling the previous owner of our Rubicon didn’t perform much maintenance on the Jeep. We had ordered some new rotors and pads from Omix-ADA ahead of time, as a quick inspection revealed the original components were heavily worn. We knew our rear pads were pretty low but were surprised to see just how gone they were.

To seal the joint, RCV created a patented cast polyurethane cap. The cap uses what RCV describes as Spherical Sealing Technology. Unlike a traditional rubber boot that is more susceptible to damage, the SST boot is more durable. While the RCV CV-joints are known to sling a little grease, they do an excellent job of keeping debris out of the expensive internals.

To seal the joint, RCV created a patented cast polyurethane cap. The cap uses what RCV describes as Spherical Sealing Technology. Unlike a traditional rubber boot that is more susceptible to damage, the SST boot is more durable. While the RCV CV-joints are known to sling a little grease, they do an excellent job of keeping debris out of the expensive internals.

Depending on the total miles and condition of the JK’s unit bearings, this is a great time to install a new set. We picked up these from Omix-ADA when we ordered our brakes. The fairly inexpensive unit bearings came fit with new studs and tone rings, making for a quick swap.

Depending on the total miles and condition of the JK’s unit bearings, this is a great time to install a new set. We picked up these from Omix-ADA when we ordered our brakes. The fairly inexpensive unit bearings came fit with new studs and tone rings, making for a quick swap.

The RCV Performance front axleshaft upgrade uses a CV-joint over a traditional U-joint. Virtually everything you see here is comprised of aircraft-quality high-alloy steel. Since the proprietary CV retains strength through its range-of-motion (up to 45 degrees), it never changes speed or loses strength as a traditional U-jointed ’shaft would. The black coating comes standard, and a nickel-plating is also offered for those looking for increased corrosion resistance.

The RCV Performance front axleshaft upgrade uses a CV-joint over a traditional U-joint. Virtually everything you see here is comprised of aircraft-quality high-alloy steel. Since the proprietary CV retains strength through its range-of-motion (up to 45 degrees), it never changes speed or loses strength as a traditional U-jointed ’shaft would. The black coating comes standard, and a nickel-plating is also offered for those looking for increased corrosion resistance.

To install the front ’shafts, you’ll need to breakdown most of your outer front end components, minus the steering knuckles. This will require a 12-point 13mm (unit bearing bolts), 21mm (brake caliper brackets), and a 35mm for the axle nut.

To install the front ’shafts, you’ll need to breakdown most of your outer front end components, minus the steering knuckles. This will require a 12-point 13mm (unit bearing bolts), 21mm (brake caliper brackets), and a 35mm for the axle nut.

RCV makes it pretty easy to take care of your investment. Included with the front ’shafts was a bottle of RCV’s synthetic moly grease, which you’ll use about twice a year to keep the joints packed. Our ’shafts were fit with a needle grease fitting but standard zerk fittings are now available.

RCV makes it pretty easy to take care of your investment. Included with the front ’shafts was a bottle of RCV’s synthetic moly grease, which you’ll use about twice a year to keep the joints packed. Our ’shafts were fit with a needle grease fitting but standard zerk fittings are now available.