Pete Trasborg

Brand Manager, Jp

Photographers:

Tony Rojo

Pete Trasborg

Brand Manager, Jp

Photographers:

Tony Rojo

It seems like part of being a Jeeper is that no matter what we've got, we want something different or better. If we have all-terrain tires, we wish we had mud tires. If we have a soft top, we're jealous of our friends with the milk-mobiles and grocery-getters, who wheel in shade and A/C. If we're in a Cherokee, we envy the open-top, doorless experience our Wrangler friends take for granted.

Well, we have found a way the tin-can guys can enjoy the best of both worlds: a roof overhead when it rains, and sunshine on the shoulder when it's nice out. We cut a 3x6-foot hole in the top of our friend Tony's Jeep, and he not only thanked us afterward, but he still talks to us today (a month or two later).

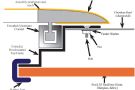

The reason he still speaks to us is because we installed a Street Beat Customs canvas ragtop to seal up the hole. At the end of the installation, we took the Jeep for a drive and some mild wheeling. Top closed or open, the wind noise wasn't bad at all, and Tony thinks it might be quieter with the ragtop than it was without.

Street Beat Customs is a mini-truck and street-oriented company, but don't hold that against it. It offers an array of ragtops in various colors and sizes. Power units are also available, although we went with the manual one here. And for guys in cold climates, you can get a liner for the top that will help keep the heat in the Jeep in the winter. Just call and talk to Rick, and ask for the Cherokee top like Jp installed. Smaller sizes are available, but we went with just about the biggest hole we could cut and the canvas still opens correctly on the Jeep.

Now, picture a big cardboard box. When the flaps are taped closed, it's pretty rigid. When you open the top, though, the box becomes flexible and can be easily crushed. The Cherokee isn't much different from that box. We cut a huge hole in the top (the same as opening the flaps) and therefore needed to find a way to prevent our box from crushing. A full cage tied into the pillars would be by far the best way, but we were trying to maximize that open-air feeling.

Follow along as we cut the top of a nice Cherokee that isn't even ours, and you can decide whether this is something you might want to do with your own Jeep wagon.