Pete Trasborg

Brand Manager, Jp

Pete Trasborg

Brand Manager, Jp

It isn’t easy, but there comes a time with everything when you just need to stop throwing good money after bad. The trick is to realize that pivotal point and admit it to yourself. In this case, we are talking about the Dana 35 in our 1997 Jeep Wrangler. When the TJ came out in 1997, it broke all kinds of molds and was an awesome out-of-the-box performer. However, one thing that didn’t change was the craptastic Dana 35 rear. Sure, a Dana 44 was rumored to be available soon (it didn’t actually show up until almost halfway into the 1998 production), but if you wanted a better riding, better handling, more civilized, and better wheeling Jeep ASAP, you got it with basically the same rear axle the YJ had.

While this Jeep has been whipped, dragged, and beaten, we’ve never had bigger than a 31-inch tire on it, so the Dana 35 was bravely soldering on. The automatic transmission helped things, too. But after 17 years of use, the slop between the ring and pinion was epic, there was some kind of crunchy noise coming from the pumpkin, there was a lot of end play in the axleshafts, and chunks of metal were found in the gear oil. It was time for a full rebuild. Or was it?

We were on the cusp of lifting the Jeep for the first time in its life. Truth be told, we were lifting it as much because all the factory stuff was completely hammered as anything else. The control arms were bent, the bushings were shot, the springs were comically sagged-out, we couldn’t remember the last time the shocks worked well, and a decent lift would replace all those parts cheaper than we could replace them with factory-spec parts. Even if we weren’t lifting it, we have been in a lot of spots where we wished we had a rear locker, so that was added to the rebuild parts list. Also, the Dana 35 had a slight bend in it, and while it was serviceable, well, it was still a bent Dana 35. While it takes us some time, we can setup our own gears. If you can’t, add about $500 to our total below. Here’s how the prices break down for what we were planning.

Full Rebuild/Regear Dana 35

G2 gears $187.99

G2 master rebuild kit $122.99

Axleshaft bearing kit ($55.99 each side) $111.98

ARB air locker $1,040.99

Drum brake kit $224.99

Local cost of labor to put new bearings on axleshafts $150.00

Total $1,838.94

So, we’d have almost $2,000 into our slightly bent Dana 35 rear axle, still have the tiny 27-spline axleshafts with C-clips, the small ring-and-pinion, and that’s not counting paint or any parts that might be missing from the full rebuild kit and our time, which would likely come in at around two full days. Since we don’t setup gears every day, it can sometimes take a while. This Jeep is a daily-driver, so we’d be cutting it close to get the whole thing done in a weekend.

We decided, just for kicks, to take a look at bolt-in, pre-assembled rear-axle assemblies. Not only would it be faster for us to put in the Jeep, but most of them come with warranties, which we wouldn’t have if we built it ourselves. After running through the biggest names in the game we found even a run of the mill Dana 44s would be more than double our rebuild number. Then we found G2 axle assemblies. With the gears we were looking at and the ARB Air Locker already in there, we found a Dana 44 with 35-spline chromoly shafts ready to bolt in for $2,667.99. That’s just over $800 more than our at-home rebuild for a huge increase in strength, and the assembly would bolt into our TJ. So, we ordered one up and had it delivered to our local 4 Wheel Parts store to save a bit on shipping. Here’s how it came together.

Pay attention or you might find yourself taking it back apart

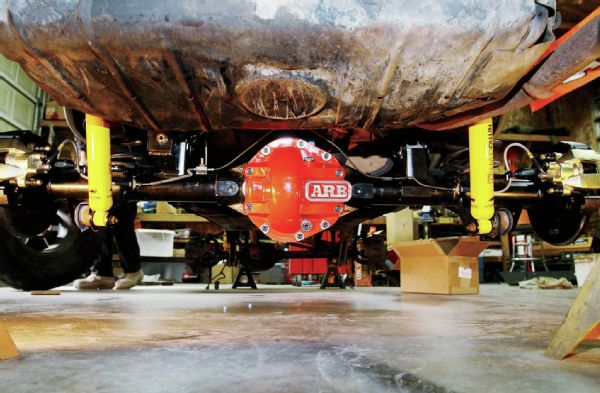

Here is our $2,667.99 gem as delivered. Note that the price includes a heavy-duty aluminum G2 differential cover, but we opted for no brakes, thinking we’d be able to reuse our existing brakes. The gears are setup, the ARB Air Locker is already in there with a fitting poking through the housing, and in general this axle is ready to rock-and-roll. But, we decided to poke around inside it first.

The first thing we did was pull the cover. These axle assemblies ship with no gear oil, so make sure and fill ’er up before you run off driving down the road. We were able to see the setup pattern on the gears, and it looked dead-on on both the drive and coast side of the gears. Right there we would have blown at least a day trying to get a pattern like that.

Here’s a comparison of the new 35-spline chromoly Dana 44 shaft (left) and the pathetic factory 27-spline C-clip Dana 35 shaft (right). In one fell swoop we got rid of the C-clips and the small-diameter shafts while upgrading to chromoly. The biggest tire this Jeep is likely to see is a 35-inch-diameter mud tire, so these shafts should be the last set we ever need.

Out at the wheel end of the shaft, you can see it is dual-drilled. We are still using the factory 5 on 4.5-inch bolt pattern, but the shafts are also drilled for the larger 5-on-5.5-inch bolt pattern as well. That is useful if we ever go to front locking hubs or swap the front axle down the road. Also note that the axleshafts make use of the better screw-in style of stud.

We thought we were going to be able to reuse our existing drum brakes. We were wrong. The stuff on the Jeep was so hammered we wondered if it was actually doing any stopping anymore. Fortunately, G2 offers brakes as well. We took the opportunity to upgrade to rear discs. This kit is $499.99, includes everything but parking brake cables, and can be retrofitted to any TJ Dana 35 or Dana 44 rear axle.

While we were planning on replacing control arms and whatnot, that wasn’t in the budget for today, so we removed and reused all the factory control arms, even the trackbar. We had some issues getting that Torx bolt to let loose, so we threw the old axle up on the bench for better access.

To prove just how easy the G2 axle made our life, a pair of chicks installed the axle. On the left is Chloe Bowen and she actually owns the Jeep. On the right is Abby Whitney who has owned a few Jeeps of her own. While both have done oil changes and brakes, this was their first axle swap but it came off without a hitch. So don’t be afraid of the project if you’ve never swapped axles before. It is doable.

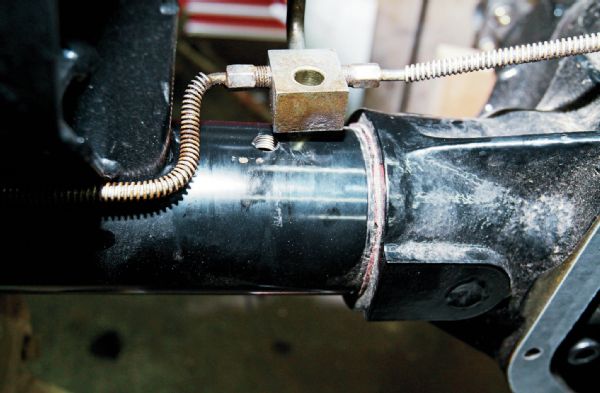

We also reused the factory hard brake lines but had a small issue with the distribution block. Because the G2 control arm and trackbar mounts are so much bigger and beefier, where the flex line drops to the axle, we had problems bolting the distribution block back into the axle. We were finally able to get it with some creative line bending, but we would have liked to see this hole about 1⁄2-inch to the right.

At the other end, because we were upgrading to disc brakes, we cut and flared the hard lines. The G2 axle comes with the retaining tabs for the flexible disc brake line welded to the axle regardless of what brake option you choose so we knew exactly where we needed to cut the hard lines.

The G2 axle assembly tubes come pre-drilled and tapped so that we were able to reuse all our factory bolts. That included the bolt to hold the distribution block we mentioned earlier, but it even included the bolts for the long-side brake line retaining bracket. We had to trim the bracket to clear the bigger housing of the Dana 44, but once we did, we were able to bolt it back down using the bolts off the factory Dana 35.

The G2 housing has 3⁄16-inch-thick brackets which make the factory brackets look flimsy. Somehow we only slightly bent a few of the factory brackets, but with hard use and bigger tires, we’ve seen plenty of them rip right off the axle. The factory Jeep welds can leave a little to be desired, but the welds on this axle all look great. We are confident these will stay where they were put. The laser-cut G2 emblem was a nice finishing touch as well.

Do yourselves a favor -- take the time to inspect your brakes before ordering your new axle assembly. The installation of the brake kit wasn’t that hard, but we added a ton of work for ourselves over had we ordered the axle with the brakes installed. With these newer Dana 44s, we like to put some silicone on the flange to help prevent leaks. Compared to the thin-walled factory Dana 35, this Dana 44 features 0.250-inch-thick axle tubes.

We also like to apply silicone to the outside diameter of the wheel seal. In addition to helping to prevent leaks, if the housing is worn, it will keep the seal from spinning in the housing. To the right of the seal you can see a spacer. The spacer is needed for the disc brakes because the disc brake backing plate is so much thicker than the drum brake backing plate. We had to have a local shop cut the bearings off the shaft to install the spacer and then put new bearings back on.

Sliding the axleshaft home is easy. Getting the spacer through the center hole of the backing plate and in place and keeping it there is a bit trickier. We had to use a couple of right angle picks to get around the axleshaft flange to get the spacer where it needed to be while we were tightening the axle retaining bolts. Again, don’t do as we did -- check your brakes before ordering.

The snout of the Dana 44 is over 1-inch longer than that of a Dana 35. We are planning on lifting this Jeep soon so our existing driveshaft should work. However, if you aren’t lifting the Jeep, you will need to have your driveshaft modified to work. We also opted for the U-bolt style pinion yoke which gets rid of the problematic strap-style retainers.

When swapping from drums to discs, it is also necessary to swap the parking brake cables. We were able to reuse the front cable and adjuster up near the body, but the cables out to the axle needed to be swapped. We ordered replacement cables from G2 (top). Shown below are the factory 2001-and-up Jeep disc brake parking brake cables.

We ended up replacing the aluminum G2 cover with ARB’s cast steel cover because the G2 cover was too close to our gas tank skid. Plus, the ARB cover has a gnarly magnetic drain plug, and a fill hole with a dip stick attached to the fill hole plug for easy level checks and adjustments. The axle can be ordered this way if desired.

Here is the finished assembly ready to go. Make sure to spray the rotors with brake cleaner before installing. Even if our hands were clean, the slotted rotors ship with some kind of protective coating that might gum up the brake pads. Be careful when assembling the components as the rotors, backing plates, and calipers are all side-specific. While they do only go together one way, pay attention or you might find yourself taking it back apart to the axlehousing flange to do it right the second time.

Even with the added work of having to install the brakes ourselves, we were able to go from one axle to the other in under a full day’s worth of work. Here is the finished and installed upgrade that should easily last us for another 20 years (if the Jeep itself lasts us that long).