When contemplating an engine project, there are many reasons to consider starting with a brand-new block. Sometimes the move is predicated on a power threshold that demands new metal in beefy aftermarket form, though other build goals can play just as vital a role in this choice. In the case of our slant-six-equipped project '68 Valiant, we decided from the onset to take the path less traveled, and opt out of the typical small-block swap in favor of big-block power. Taking things a step further, the basis of the build would be Indy's aluminum Maxx block. While this might seem like the realm of the exotic, as Indy's Ken Lazari tells us: "Believe it or not, it is not much over about a $2,000 upgrade to any engine, so it's not out of this world as far as extra cost, and that's why we build a lot of them. These things are nose-heavy to begin with and it takes the weight off the car, it improves cooling, and, of course, you won't end up splitting it five years from now-it's going to be in there for a long time. If you want a car that's going to handle and want to take the weight off the nose and beat on it hard, the Indy Maxx block is a good option."

Block Basics

The Maxx block is cast in the United States in the state of Ohio and is fully water jacketed, with siamesed cylinders. Since the machining to the bare casting is all done at Indy Cylinder Head, the block is available in a wide range of configurations, including both tall- and short-deck Wedge or Hemi versions. OEM Mopar big-blocks came in two distinct flavors, the low-deck "B" engine with a factory deck height of 9.98 inches, or the "RB" with a deck height of 10.725 inches. In the tight confines of an A-Body engine compartment such as our '68 Valiant's, the compact low-deck B-engine is definitely an easier fit.

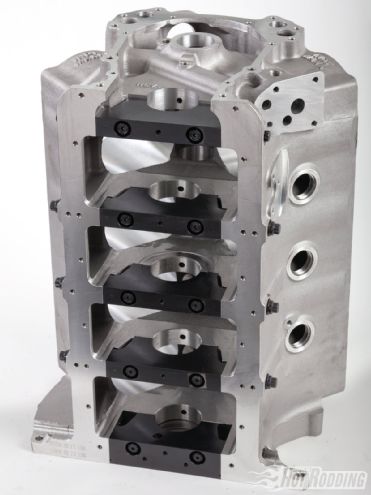

Want big Mopar power in a lightweight package? The Indy Maxx low-deck Wedge block that forms the backbone of our Mopar build weighs in at just 133 pounds, well under half the weight of an aftermarket iron block. Our combination at 500 ci is well under the block’s maximum displacement capacity.

Want big Mopar power in a lightweight package? The Indy Maxx low-deck Wedge block that forms the backbone of our Mopar build weighs in at just 133 pounds, well under half the weight of an aftermarket iron block. Our combination at 500 ci is well under the block’s maximum displacement capacity.

For our engine project we selected the low-deck Wedge Maxx engine, which, unlike the factory low-deck engines, features the 440-sized 2.750-inch mains, rather than the OEM 2.625-inch dimension, for a broader range of crankshaft choices. Speaking of mains, the reinforced bulkheads of the Maxx block's bottom end feature Indy's billet caps with cross-bolting at all five mains, rather than just the center three as in factory Hemi blocks. As Lazari details: "When the block was designed, we strived to make that thing lightweight, strong, and stable; it's got to be stable. That block is 133 pounds ready to go." Major revisions of the lubrication system are also incorporated into the block, with priority main oiling and a unique oil pump pickup arrangement routing oil from an external line to feed a standard big-block Mopar-style oil pump from a passage at the front of the block. This clever setup provides much needed internal clearance for large stroker cranks, a problem area with the production internal pickup. The block also has provisions in the valley to supply oil feed lines to bosses providing top end oiling in the OEM deck location, rather than requiring external lines.

By The NumbersIndy 500 Mopar Wedge Short-Block Block: Indy Maxx aluminum Bore: 4.375 Stroke: 4.125 Displacement: 500 ci Deck height: 9.98 inches Main caps: Indy billet Main bearings: Mahle Clevite 1795V Rod bearings: Mahle Clevite 537HN Main clearance: .0035 inch Rod clearance: .003 inch Connecting rods: Eagle 6.76-inch H-beam Pistons: Diamond forged dish Rings: Total Seal 1/16, 1/16, 3/16 inch Cam: COMP solid flat tappet Duration: 245/251 degrees at .050 Lobe lift: .372-/.372-inch Lobe separation: 108 degrees Installed centerline: 106 degrees Crank damper: ATI Oil pump: Melling Oil pan: Moroso Windage tray: Mopar Performance

A look at the Maxx block from below reveals the massive bottom-end structure of the Maxx. Five cross-bolted billet mains in a deeply skirted structure make for a nearly indestructible setup. Indy reports power handling capacity in excess of 2,500 hp in power-adder applications.

A look at the Maxx block from below reveals the massive bottom-end structure of the Maxx. Five cross-bolted billet mains in a deeply skirted structure make for a nearly indestructible setup. Indy reports power handling capacity in excess of 2,500 hp in power-adder applications.

Fillin' The Bottom

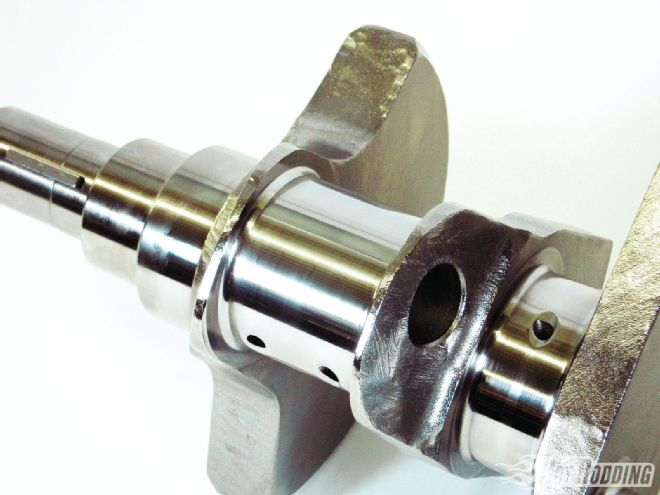

Although the Maxx block can easily swallow bore sizes of over 4.500 inches, the plan for the short-block was to build to a displacement of 500 ci via 4.375-inch bores and the popular 4.125-inch stroke. The arm is an Eagle forged stroker crank, a common off-the-shelf piece, treated to Eagle's ESP Armor process. Lazari spoke highly of the Armor treatment: "It is slick, I can tell you that. It mic'ed out really good. The extra treatment makes the surface really good." The crankshaft rides on Mahle Clevite 1795V main bearings and the assembly is secured with top quality ARP hardware. Working in concert with the Eagle crank are a set of 6.760-inch Eagle H-beam rods using a standard Mopar-style big end and a big-block Chevy spec .990-inch wristpin bore. This configuration is an off-the-shelf item from Eagle. Rod bearings are also Mahle Clevite, PN 527HN, run at .003-inch clearance.

Mahle Clevite bearings were used throughout the assembly of the bottom end, with the main clearance set to .0035 inch and .003 inch at the rod bearings.

Mahle Clevite bearings were used throughout the assembly of the bottom end, with the main clearance set to .0035 inch and .003 inch at the rod bearings.

Speaking of clearances, Lazari explains: "We set it up like a race engine; we run about .0035 inch or even as much as .0004 inch on the mains, requiring a 20-50 weight oil." The pistons are custom from Diamond, with a substantial dish to get the compression down with the large displacement and the Mopar's relatively compact chambers." Lazari continued, "We went with Teflon coating on the piston skirts to reduce friction, and used a .200-inch wall pin. The rings are a 1/16-, 1/16-, 3/16-inch conventional moly set from Total Seal; it's all heavy-duty stuff. The only thing about the combination is that you are running a short piston. It took a little while, but it sealed up pretty good, and it's not noisy either; that's what I always worry about with something like that, but it's pretty quiet."

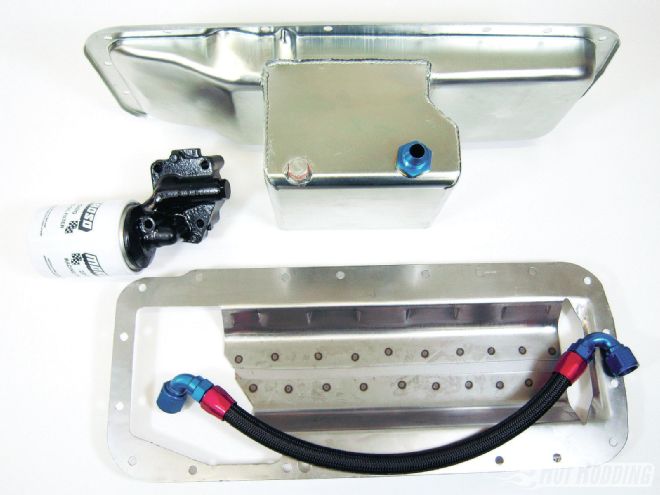

The bottom end is closed with a Moroso oil pan sporting a Mopar Performance stroker-spec windage tray sandwiched between the pan and the block. The pan was modified for the external pickup by Indy, using their rear-mounted static pickup kit, routing the oil through a -12 AN fitting. Lazari remarked: "That line might look like it has goofy angles, but believe me, having put enough of these into cars, it clears the K-member and any type of Mopar suspension; it clears everything."

With the reciprocating assembly handled, the camshaft represented the next key element of the parts selection process. Weighing the alternatives, Lazari decided that a solid flat-tappet would offer the best balance of longevity and performance. The COMP Cams grind specs to 245/251 degrees duration at .050-inch tappet rise, with .371/.382-inch lobe lift, and was ground on a lobe separation angle of 108 degrees. Lazari detailed: "We put a solid flat-tappet in with the plasma nitride hardening, so there's no worrying about it wearing out. The specs are pretty modest. With a motor like this you can put 280 degrees duration [at .050] in it, and it will love it. But for a street application, you don't really want to drive it around like that. It will load up, it won't be responsive, and it will want a lot of converter in the trans. I kept shrinking the cam timing down until the point where any smaller would lose a lot of power. I took it down to the bare minimum; that's what it boils down to. With 5 degrees less duration it might have lost 50 hp."

Keeping the vital fluids in check are a Moroso oil pan and a Mopar Performance windage tray. The Maxx block relies on an external pickup routed to a conventional Melling pump through a provision at the front of the block. Indy modified the Moroso pan to accept their rear-mounted static pickup and external feed line.

Keeping the vital fluids in check are a Moroso oil pan and a Mopar Performance windage tray. The Maxx block relies on an external pickup routed to a conventional Melling pump through a provision at the front of the block. Indy modified the Moroso pan to accept their rear-mounted static pickup and external feed line.

With the trick aluminum Indy block, the entire engine package will tip the scales considerably less than an iron small-block, yet the power and torque of a 500-inch big-block will not go unnoticed. The block alone represents over a 100-pound savings compared to a production block, and nearly double that compared to some aftermarket iron block variants. Indy relates they have had these blocks in supercharged and turbocharged applications up to 2,500 hp. Lazari tells us that at a street power level, the bottom end will maintain its dimensions and last just about forever. Reliability and performance at substantially fewer pounds per horsepower are convincing reasons to consider an aluminum block as a basis for your build.

Next month, we'll take a look at the cylinder heads and induction, and put the 500ci Indy Maxx Wedge on the dyno. Stay with us!

Eagle's ESP Armor

Looking at an Eagle crankshaft with their ESP Armor finish, what becomes immediately evident is that the surface is as smooth and shiny as chrome. ESP Armor is not a coating, however, nor is it an electroplating process, but is rather an exclusive surface finishing process that imparts the signature mirror-like surface. The process does not actually change the part's dimensions, but it does provide quantifiable performance advantages. According to Eagle, the ultraslick journal surfaces make more effective use of the thin film of oil between the bearing and crank, for added protection against failure at this critical area. Since the treatment covers the entire surface of the crank, oil shedding is reduced for potential power gains from reduced windage. Add in greatly improved corrosion and crack resistance, and you have a winning combination. Dyno testing from Eagle and testimonials from their customers cite significant power gains. For the details, visit www.eagle-rods.com.