The day finally arrived when our 467 ci of pure Pontiac would be bolted to the Stuska dyno at RaceKrafters. Its machining and assembly, along with the parts sourced from Summit Racing and Butler Performance, would be on trial—the jury being the Depac data acquisition system, and the verdict read as horsepower and torque.

Our test Mule is a nice mill but it isn’t exotic. It’s a standard bearer of what most readers would build for a street/strip Pontiac: 9.1:1 compression, ported 6X cylinder heads, along with a stroker crankshaft. The most exotic (for lack of a better word) part of the engine is the hydraulic roller camshaft, and even it is being used more regularly in hobbyist buildups.

Since we needed to get a lot done in one day, both Bob and Craig tag-teamed the Mule engine to make changes. (No, they aren’t making two tuning changes at once—this was just set up for the photo.)

Since we needed to get a lot done in one day, both Bob and Craig tag-teamed the Mule engine to make changes. (No, they aren’t making two tuning changes at once—this was just set up for the photo.)

The Mule’s conservative DNA will be a starting point for our long-term objective of using this engine as a test bed. Thus, we set a realistic goal for power. Though it is not admitted, anyone who goes to a dyno with an unknown combination always has a number in mind. Anything below that and they will be disappointed. If it is higher, they are ecstatic. Our goal was just over 467 real horsepower, or one pony per cubic inch on pump gas.

The word real as a description of horsepower was chosen for a reason. One of the many motivations to work with Bob and Craig Wise was the accuracy of their dyno cell, along with their engine building and machining skills. Accurate and repeatable testing is the essence of this project as it moves forward. A dyno cell or operator that unintentionally introduces a number of variables into the testing would skew the data and, for the most part, make it worthless. If HPP is going to qualify and then quantify parts and modifications, we need an accurate test cell. RaceKrafters has one.

Since we covered the requirements and function of a dyno test and test cell in the primer that preceded this story, now we’ll discuss the power that our Pontiac produced, along with the tuning decisions.

The dyno controls are a combination of mechanical parts, human interaction, and computer function. Even though the computer controls the run, Craig stands ready as he watches the instruments to abort the pull if something goes wrong.

The dyno controls are a combination of mechanical parts, human interaction, and computer function. Even though the computer controls the run, Craig stands ready as he watches the instruments to abort the pull if something goes wrong.

Before HPP arrived at RaceKrafters, the Mule had been already bolted to the dyno, test run, and partially broken in. You always want to run a fresh engine with a varying amount of load (not full load) to get all of the parts seated. The crankcase was filled with Brad Penn 30W break-in oil.

The Holley mechanical secondary 750-cfm carburetor (PN 80528-2) came with No. 73 jets all around and a 6.5-inch of Hg power valve. An MSD Pro-Billet Ready-To-Run distributor also had an out-of-the-box advance curve setting with two heavy silver springs along with the blue bushing. The mechanical advance was to be all in by 4,000 rpm and the total timing was set by Craig to be 34 degrees BTDC.

Our Mule started immediately and ran beautifully with excellent oil pressure and built coolant temperature evenly. Prior to HPP arriving, Craig made some partial pulls and with everything looking good, shut it down, and waited for us to show up the next morning.

Craig adjusts the timing while discussing the tuning with the author. We began testing with a total of 34 degrees timing BTDC. We then tried 32 degrees and the power picked up slightly. That was the sweet spot for this engine. At 30 degrees, power dropped off.

Craig adjusts the timing while discussing the tuning with the author. We began testing with a total of 34 degrees timing BTDC. We then tried 32 degrees and the power picked up slightly. That was the sweet spot for this engine. At 30 degrees, power dropped off.

When we arrived at the shop, it was exciting to see the Mule attached to the dyno brake and ready to rumble. With it fired and idling around 1,000 rpm (to build heat quicker) we anxiously awaited for the oil and water temperature to rise. Once the water hit 151 degrees F and the oil 128 degrees F, the time of reckoning had come. The fuel cell was already filled with 92-octane gasoline from a local station. The Pontiac was going to have to show us its mettle against the stout Stuska water brake.

With the Depac system set to make a run from 3,000 rpm up to 5,550, Craig crowded the throttle control until it was fully open and pressed a button telling the control servo to begin the run. The Poncho sounded like a NASCAR engine as it challenged the hydraulics of the water brake. It sung one sweet song and never missed a beat. The entire run from beginning to end took only 8.4 seconds. With the throttle fully closed, the 467 quickly obtained an idle status of 850 rpm without a quiver. It went from peak power to idle like a loyal soldier following the commands of his officer.

The MSD Pro-Billet Ready To Run distributor was shipped with two heavy silver springs. We changed to two light silver springs to quicken the advance rate, but saw no difference in power at WOT. Keep in mind, however, the rate of advance is best tuned on a chassis dyno during transient part throttle operation. A proper ignition curve will produce better driveability and fuel economy.

The MSD Pro-Billet Ready To Run distributor was shipped with two heavy silver springs. We changed to two light silver springs to quicken the advance rate, but saw no difference in power at WOT. Keep in mind, however, the rate of advance is best tuned on a chassis dyno during transient part throttle operation. A proper ignition curve will produce better driveability and fuel economy.

Within a second, the data was out on the PC screen and HPP is pleased to report that we exceeded our goal on the first pull with hardly any break-in and the out-of-the-box settings for the carburetor jets, air bleeds, and distributor timing.

Peak hp was 484 at 5,000 rpm; maximum torque was 546.5 lb-ft at 3,600 rpm. More importantly, from 3,400 to 5,500 rpm the average horsepower and torque were 430.36 and 528.02, respectively. There was over 500 lb-ft of torque at nearly every test point. This engine in even the heaviest Pontiac would pull like a jet on take-off!

The Holley carburetor provided a good deal of adjustability, since all of the air bleeds and metering block orifice holes are threaded. It also boasted a four-corner idle circuit, which would not be of benefit on the dyno but an asset with the engine in a car. The BSFC numbers are used to help shape the fuel curve. Changes to the air bleed size will move the slope, while jet changes tend to move the entire fuel delivery up or down. The Holley’s as-delivered high-speed air bleed size is 0.034. We tried 0.036 and 0.038 with no improvement. We did not alter the low speed bleeds.

The Holley carburetor provided a good deal of adjustability, since all of the air bleeds and metering block orifice holes are threaded. It also boasted a four-corner idle circuit, which would not be of benefit on the dyno but an asset with the engine in a car. The BSFC numbers are used to help shape the fuel curve. Changes to the air bleed size will move the slope, while jet changes tend to move the entire fuel delivery up or down. The Holley’s as-delivered high-speed air bleed size is 0.034. We tried 0.036 and 0.038 with no improvement. We did not alter the low speed bleeds.

Each run we made was backed up by at least one other to confirm the data.

During the inaugural pull, the BSFC (brake specific fuel consumption) and fuel flow looked great. The Pontiac was very efficient given its compression ratio, with an average BSFC of 0.398 for the entire pull with a low value of 0.37. Fuel flow averaged 173.06 pounds with a low of 131.3 at 3,400 rpm and a peak of 214.8 at 5,500 rpm. At that speed, the engine was 500 rpm beyond peak power, and thus the fuel consumption and BSFC all went high. The BSFC jumped to 0.44 and the fuel rate to nearly 215 pounds. This is normal for an engine when it’s beyond its efficiency range, since it is working hard but cannot pump any more air. Think of it as a runner gasping for breath.

Craig tried both smaller and larger jets to get a feel for what the engine wanted even though all the numbers were good. We ended up back with the original #73 jets in all four corners.

Craig tried both smaller and larger jets to get a feel for what the engine wanted even though all the numbers were good. We ended up back with the original #73 jets in all four corners.

With the fuel readings looking so good, we went to look for extra power in the ignition timing. Craig ran a loop that varied from the starting point of 34 degrees and then went lower. If the engine power would have dropped off, he would have then went above 34 degrees. As it was, the Pontiac liked 32 degrees of timing best. Even though it only picked up a few horsepower, on the average, the less timing you can run the better it always is because it will be less prone to detonation.

Though we played with the jets and air bleeds on subsequent pulls, lack of improvement brought us back to the factory Holley settings. Bringing in the timing quicker using lighter springs had little effect on power as well (but they didn’t hurt, so we left them in). If you order the carburetor and distributor correctly, the tune should be pretty close right out of the box.

Stock float height as measured with the bowl inverted (not the normal position when on the engine) can vary from around 0.950 inch to 1.250 inch. Craig set the float at 1.100 inch using a caliper to be extremely accurate. This setting worked best on the dyno. This may not be the case with a drag car that launches hard though—the height might then have to be altered slightly.

Stock float height as measured with the bowl inverted (not the normal position when on the engine) can vary from around 0.950 inch to 1.250 inch. Craig set the float at 1.100 inch using a caliper to be extremely accurate. This setting worked best on the dyno. This may not be the case with a drag car that launches hard though—the height might then have to be altered slightly.

Best Pull Details

#73 jets (square), 32 degrees of total advance, two light silver springs and blue bushing, 92-octane, 1-inch-open carb spacer

The next and final step for the day was to install a one-inch open spacer and retest. This increased the power to a peak of 491.8 and the torque to 551 lb-ft. The average numbers went up to 533.73 for torque and 435.16 for power. Interestingly, the jetting and timing wanted to be exactly the same, but the average BSFC came down slightly to 0.384 and the total fuel dropped to 172.53 pounds. Our Pontiac was making more power and using less fuel, since it accomplished the task more efficiently. That’s what dyno testing and tuning are all about.

A carburetor spacer helps steer the charge by raising up the throttle plates from the floor of the plenum of the manifold. This is especially true with an application such as ours where the manifold sits very close to the height of the cylinder head.

A carburetor spacer helps steer the charge by raising up the throttle plates from the floor of the plenum of the manifold. This is especially true with an application such as ours where the manifold sits very close to the height of the cylinder head.

In all we made almost 70 dyno pulls since the engine went on the dyno stand for break-in. With an impressive baseline established, let the testing begin!

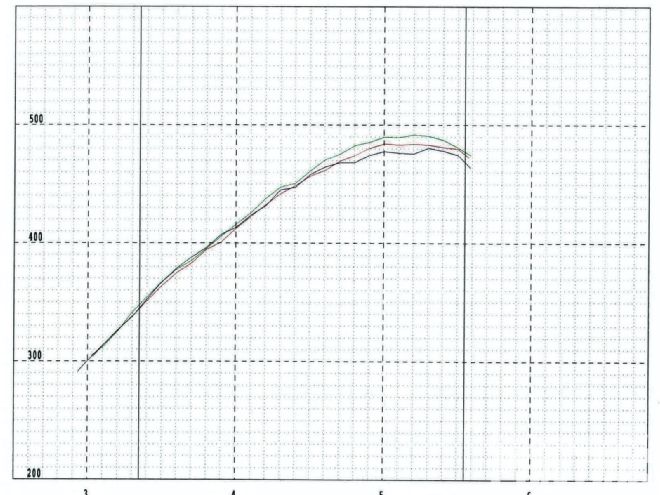

Three Pulls: Horsepower Only

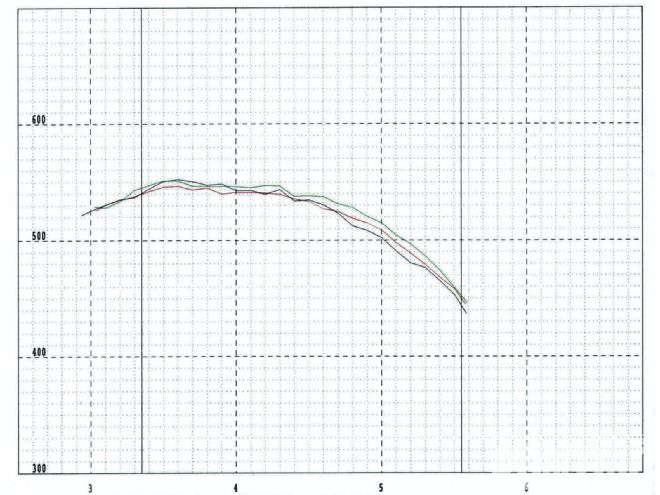

Three Pulls: Torque Only

Red

This was our initial pull of the Mule. Peak horsepower was 484 at 5,000 rpm and torque was 546.5 lb-ft at 3,600 rpm. The average for torque and horsepower were 528.02 and 430.36, respectively. The engine had 92 octane fuel, 34 degrees of total timing, and #73 jets.

Blue

Here we tried to make things better but the Mule did not like it. We kept the jets the same but since the engine responded to 32 degrees of timing instead of 34 we tried 30. It lost about 4 hp and a like amount of torque at peak. The average only fell to 527.99 lb-ft of torque and 429.93 hp.

Green

This was our best pull of the day and it was with the 1-inch spacer and 32 degrees of timing along with the No. 73 jets. With 551 ft-lb and 491.8 hp, it was about 8 hp better on power than the baseline, and 4.5 lb-ft better on torque—a nice gain for a carb spacer.

HPP Engine Buildup Worksheet

Engine displacement: 467 ci

Bore/stroke: 4.185 / 4.250-in

Bore/stroke ratio: 0.98:1

Rod/stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Preparation: Cooked, magged, line-bored, line-honed, decks squared with BHJ, bored and honed with torque plates

Deck height: 10.205-in

Crank: Butler/Eagle forged

Preparation: Balanced, polished

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Preparation: Pin end honed to proper size, balanced, big end checked for proper size

Bearings: Clevite, plain shell, tri-metal

Preparation: Clean, check for proper clearance in rods

Pistons: Butler/Ross forged flat-top with valve reliefs

Preparation: Pin fit, check size, clean

Piston-to-deck height: 0.010 below

Piston pins: Ross, 0.990 floating, 0.155-in wall

Method used to retain piston pins in pistons: Spiro Locks

Rings: Total Seal, moly top, ductile second, three-piece oil; 1⁄16-, 1⁄16-, 3⁄16-in

Preparation: File-fit, clean

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road RaceSeries 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2ccs

Maximum flow at 28 inches of pressure:

Lift

Intake Flow CFM

Exhaust Flow CFM

0.100

66

55

0.200

133

106

0.300

191

149

0.400

224

170

0.500

236

182

0.600

250

186

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job: Intake—45, 60, 75, and 82-deg, 82 is hand-blended into 75-deg., exhaust—45-deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valveguides: K-line bronze liner

Valve seals: Steel/Viton

Rocker studs: ARP 7⁄16-in

Rocker arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 3⁄8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration at 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe separation angle: 110-deg

Installed position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat pressure: 137 lb/in

Open pressure: 290 lb/in

Timing chain: Comp Cams double-roller

Induction

Carb: Holley 4150 HP 750-cfm, mechanical secondaries

Intake manifold: Edelbrock Torker II

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5mm

Exhaust

Headers: Hooker

Primary tube diameter: 1.75-in

Primary tube length: 32-in

Collector size: 3.00-in

Gaskets

Brand: Fel Pro