If you're a hard-core Chevrolet small-block engine guy, the good news about all the attention the LS engines are getting is there's never been a better time to build a budget Gen I small-block. That even applies to the nearly extinct 400 small block. Vigorously hoarded at one time, a few have appeared at the swap meet, and we even saw one at the junkyard not long ago. This prompted us to consider the ultimate budget tire-smoker when we received a scum-encrusted 400 small block from Hot Rod's David Freiburger. He swore it was good but abandoned it when he realized its value was declining faster than President Obama's approval rating. Other than the fact that it was a standard-bore block with stock parts, there was little to value in this casting. In fact, our theory is he found the 400 small block at the bottom of a deserted mine shaft under 100 feet of boric-acid-laced water, explaining why our block looked hideous even after a hot tank dunk. The Chevrolet gods demanded an exorcism, but we ignored 'em. Even after an abbreviated séance in which the ghost of Zora Arkus-Duntov threatened to cancel our lifetime membership in the Bow Tie cult, we pressed on. Those were valid warning signs. We decided to build a motor in a way that all good car crafters would understand-by hacking the budget with a blunt instrument. Sure, we took a risk by not boring the block and adding new pistons. The old pistons were in decent shape even after we beat them out of the block with a hammer! We even chose to ignore the serious rust pitting in the cylinder walls. We were not deterred.

We should have been, though, because the mechanical gods got the last laugh.

Our power plan was as simple as it was cheap. We liked the idea of enhancing the 400's strength of torque with a pair of Vortec iron heads and a budget flat-tappet cam to see how much grunt we could make. Then we'd pump the power with a set of large-port Vortec Bow Tie heads. So now that you know the backstory, we'll fast-forward to the assembly effort, dyno testing, and subsequent bloodletting.

Assembling the 400 Small Block

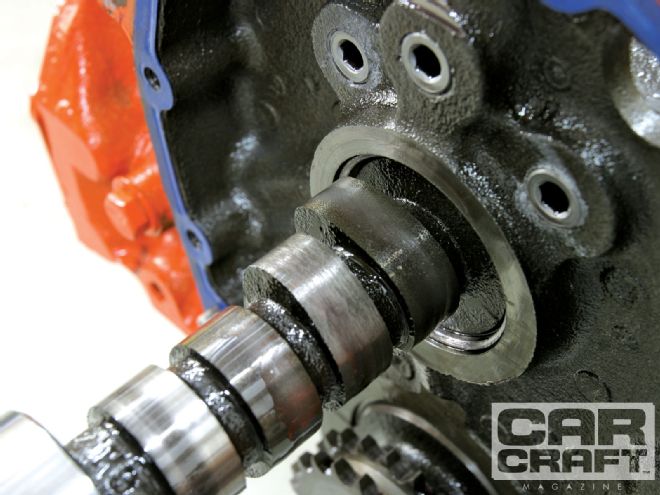

The smart move would have been to bore and torque-plate-hone the block. But since the push was to hit this short-block cheaply, we decided to stick with the game plan despite evidence of neglect. So this is our worst-case scenario. As you can see from the honing photo, there is power to be gained from doing the correct machine work by boring the block to eliminate the bore wear. We also kept to the bargain-basement plan with Summit's own cast-iron rings and basic bearings. We did have to grind the crank 0.010 inch undersize because there was metal transfer on the rod journals. Add in the cost of hot tanking, resizing the big ends of the rods, and installing cam bearings, and the machine shop cost alone came to roughly $400. Frankly, there's no way to really do this inexpensively. The days of the $1,000 V8 rebuild have gone the way of disco and Pac-Man.

Cam Specs

The cam we chose was the least expensive hydraulic flat-tappet cam and lifter set from Summit that also included a dual pattern to better support the Vortec's well-documented weak exhaust-port flow.

CAMSHAFT

DURATION AT 0.050

LIFT

LOBE SEPARATION

Summit hyd., intake

234

0.488

110

Exhaust

244

0.510

Vortec Heads

The pivotal reason for resurrecting this 400 was to create a budget short-block that could really enhance the 400's inherent torque capacity. Most everyone knows how good a bone-stock iron Vortec head flows. Did you know it's better than the old factory GM Bow Tie iron head? But there are some shortcomings as well. The stock Vortec head uses a very large-diameter valvespring guide that is also very tall, leaving barely enough room for 0.450-inch valve lift. Anything more crushes the retainer into the valveguide seal. Barrington machined our guides for 0.530-inch diameter valveguide seals, which leaves sufficient guide thickness. Unfortunately, this meant we had to purchase different valveguide seals because the Summit supplied seals are intended for 0.500-inch guides, which Barrington claims are too thin given the 0.344-inch valve stem diameter.

All this extra machine work can be avoided by merely ordering a set of modified Vortec heads from Scoggin-Dickey that will come with better springs and the machine work necessary to clear most street cams. While we were talking with Scoggin's Nicky Fowler, he suggested we also test a set of the GM Performance Products large port Bow Tie Vortec heads. These are 225cc-intake-port heads (the standard Vortecs are closer to 170, and the small Bow Tie Vortec is 185 cc), and we've seen flow numbers upwards of 250 to 260 cfm at 0.500-inch valve lift, which is excellent for these budget heads. The Bow Ties come with larger 2.00/1.55-inch valves and are machined with five angles on the seats. One Vortec issue is the specific eight-bolt intake pattern that is completely different from the traditional small-block bolt pattern, requiring its own intake. The Bow Tie heads are drilled with both bolt patterns, so if you choose to go the Bow Tie Vortec route, you can offset the $200 price increase if you already own a good aftermarket small-block intake such as an Edelbrock Performer RPM Air-Gap or a Weiand Speed Warrior. The Bow Tie Vortecs are drilled for both intake bolt patterns, which is convenient. But we discovered you need to seal the Vortec boltholes if you use a standard intake on the Bow Tie heads. The standard small-block intake manifold uncovers the Vortec bolt pattern in the head that will spew oil if the holes are not sealed. We learned this one the hard way too.

Our First Test Went Flat

Let's cut right to the chase. We screwed up. We installed the bigger, 130-pound seat pressure valvesprings on the stock Vortec heads expecting that a cocktail of moly cam lube, pressure-lubing the engine, and the prescribed quick run up to 2,400 rpm would be enough to ensure the Summit cam's survival through the break-in procedure. Unfortunately, the cam went flat. We asked a couple of engine building buddies, and the unanimous answer was that 130 pounds of seat pressure and 340 across the nose was way too much spring pressure for break-in. What we should have done, and did for the next effort, was to use the stock Vortec springs, which had enough clearance to avoid coil bind with the Summit cam. These springs measured 80 pounds on the seat and a mere 180 at 0.500-inch valve lift that is low enough to give the cam a chance to establish a wear pattern and to effectively improve the heat treatment of the lobes.

Here's what the dead cam looked like after a 25-minute break-in procedure. This was no fault of the Summit cam, as our engine buddies tell us we would have killed the best flat-tappet cam with that much spring.

Here's what the dead cam looked like after a 25-minute break-in procedure. This was no fault of the Summit cam, as our engine buddies tell us we would have killed the best flat-tappet cam with that much spring.

We decided to not take a chance on the second cam, so we ordered a Comp Pro-plasma nitrided Thumpr camshaft. The Pro-plasma heat treat hardens the lobes with a surface treatment that's roughly 0.010 inch in depth, giving each lobe an excellent chance to survive the break-in process. Of course, this also meant a new set of lifters as well as a new set of main bearings when we discovered they didn't survive the short run time due to the iron filings that were circulating through the engine.

Unfortunately, all this put us in a crunch to completely disassemble the engine to clean it (and another set of cam bearings), fix any other damage, and reassemble it so we could test again all within a rapidly closing deadline. There was no joy in Mudville.

Drilling for Steam

All 400 small-block Chevy engines use siamesed cylinder walls, creating pockets in the cooling jackets that require venting. These holes allow steam and air bubbles to vent vertically out of the block and into the heads. Unfortunately, neither the stock Vortec nor the Bow heads come with these steam holes. That means you need to perform this step. We used a stock 400 head gasket to mark the position of the holes, but note that holes closest to the intake side must be drilled at a 45-degree angle to contact the water jacket. The exhaust side holes can be drilled straight in. It's best to do this using a drill press, but since we didn't have one, we managed with a handheld drill motor.

Compression Lessons

When we began this project, it appeared that the static compression would be ideal at around 9.5:1 with the Vortec 64cc heads and a 22cc dish in the piston. This was assuming a roughly 0.020-inch deck height. So imagine our shock when we checked the deck height after reassembling the 400 to find the best cylinder was 0.062 inch down in the hole and No. Eight was buried a stupefying 0.074 inch below the deck. This created literally an 8.5:1 ratio in the "good" cylinder and a measly 8.39:1 in the worst. We also discovered that no one makes a thin steel shim head gasket for a 400, so we couldn't use a thin head gasket. We considered running a steel-shim 350 head gasket, but the gasket would protrude into the bore and cause serious detonation problems.

We masked off the chambers to prevent metal from contaminating our new heads and started with a small bit, finishing with a 1/8-inch bit for the six holes in each head.

We masked off the chambers to prevent metal from contaminating our new heads and started with a small bit, finishing with a 1/8-inch bit for the six holes in each head.

We did some further calcs, and with a 0.030-inch overbore, a zero deck height, and a smaller, 15cc dish custom piston and 0.040-inch gasket, we'd have a much stouter 10.46:1 compression, which is a full two points better than we have now. In all our years of assembling small-block Chevys, we've never seen a small-block with such miserable deck heights.

Power Day

After much chasing around to hot-tank the block again and install new cam bearings, we carefully reassembled the 400, this time with the new nitrided Comp Thumpr cam (actually, the Mutha' Thumpr) and the Comp break-in oil. We also reinstalled the lighter, 80-pound seat pressure Vortec springs, and the break-in, thankfully, went according to plan by using Comp Cams' new oil and break-in additive. This allowed us to get back to the original effort, which was to see how much power this beast could make. The power was not as impressive as it could have been because of the poor deck height and therefore the low compression, but the small Vortec heads still produced some decent torque. The power curve numbers reveal that this initial effort produced 448 lb-ft of torque at 3,800 rpm with a marginal 376 peak horsepower at 5,000 rpm. All this required 40 degrees of initial timing to achieve. While disappointed, we swapped directly to the Bow Tie Vortec iron heads to see how those larger, 225cc-intake-port heads would fare on our 400ci engine.

We were very careful with the installation of the new, nitrided Comp Thumpr cam, using the supplied lube on the lobes and the bottoms of all the lifters. While the nitriding helped, the big improvement was changing to the softer break-in spring pressure.

We were very careful with the installation of the new, nitrided Comp Thumpr cam, using the supplied lube on the lobes and the bottoms of all the lifters. While the nitriding helped, the big improvement was changing to the softer break-in spring pressure.

The results were less than spectacular, mainly because of our dramatic compression handicap. The bigger heads demanded even more timing, with 44 degrees to achieve best power. With timing and jetting maximized, the 400 managed to produce 458 lb-ft of torque at a still low 4,000 rpm, while kicking up the peak horsepower to just 401 at 5,400 rpm. As is typically the case with larger-port heads, we traded some low- and mid-rpm torque in exchange for much more horsepower farther up the rpm chart. Comparing power numbers, you can see that at 3,600 rpm is where the big-port heads began making more torque over the smaller Vortecs, carrying that power all the way up through 5,400 rpm at peak horsepower.

We also ensured the cam's survival by using Comp's new 10W-30 break-in engine oil designed for flat-tappet cams alone. If you don't have the Comp oil, then it's imperative that you use a high-zinc-content oil and the Comp break-in additive. Comp also offers a high-quality semisynthetic muscle car oil for hydraulic-flat-tappet-cammed engines.

We also ensured the cam's survival by using Comp's new 10W-30 break-in engine oil designed for flat-tappet cams alone. If you don't have the Comp oil, then it's imperative that you use a high-zinc-content oil and the Comp break-in additive. Comp also offers a high-quality semisynthetic muscle car oil for hydraulic-flat-tappet-cammed engines.

The low peak-rpm numbers are also indicative of the low static compression. The deck height's being more normal would have created roughly 9.5:1 compression, which would have kicked the power curve up in the rpm range, and all the power numbers (both torque and horsepower) would have been drastically greater. Because the pistons were sunk so far down in the hole, there was no way to machine the block to repair that problem. The correct way would be to add a 5.7-inch stroker rod and custom piston with a D-shaped reverse-deflector-style dish that would create somewhere around a 10.0 to 10.5:1 static compression ratio with a tight quench to the head using the zero deck approach. That would drastically improve the compression, the quench, and the power.

THUMPR CAM SPECS

CAMSHAFT

DURATION AT 0.050

LIFT

LOBE SEPARATION

Comp Thumpr hyd., intake

235

0.490

107

Exhaust

249

0.475

POWER CURVES

TEST 1

TEST 2

CHANGE

RPM

TQ1

HP1

TQ2

HP2

TQ

HP

2,600

401

198

402

199

- 1

- 1

2,800

395

210

392

209

- 3

- 1

3,000

391

224

389

222

- 2

- 2

3,200

407

248

410

249

- 3

- 1

3,400

428

277

433

280

- 5

- 3

3,600

441

303

447

307

+ 6

+ 4

3,800

448

324

457

331

+ 9

+ 7

4,000

447

341

458

349

+11

+ 8

4,200

443

354

452

361

+ 9

+ 7

4,400

434

363

444

372

+10

+ 9

4,600

423

370

438

383

+15

+13

4,800

410

375

430

393

+20

+18

5,000

394

376

418

398

+24

+22

5,200

375

372

404

400

+29

+28

5,400

356

367

390

401

+34

+33

5,600

375

399

5,800

355

393

6,000

333

380

Peak

448

376

458

401

Avg.

412.6

320.4

414.0

336.3

Column averages used the entire curve with data every 100 rpm, which does not appear on this chart.

PARTS LIST

DESCRIPTION

PN

SOURCE

PRICE

Used 400 short-block

used

junkyard

$120.00

Vortec iron heads, pair

12558060

Scoggin-Dickey

619.90

Vortec iron, SD-modified

SD8060A

Scoggin-Dickey

779.90*

Vortec Bow Tie, large-port

25534446

Scoggin-Dickey

985.70*

Summit piston rings, std.

133-661-00

Summit Racing

35.95

Summit oil pump, std. pressure

121155

Summit Racing

22.95

Federal-Mogul oil pump pickup

Z2241246

Summit Racing

11.95

Federal-Mogul main bearings

Z4926MA10

Summit Racing

51.95

Federal-Mogul rod bearings

Z82555CP10

Summit Racing

29.95

Federal-Mogul cam bearings

Z1235M

Summit Racing

17.95

Federal-Mogul oil pump drive

Z2246146

Summit Racing

8.95

Sealed Power gasket set

R2601016

Summit Racing

45.95

Fel-Pro Vortec intake gasket set

1255

Summit Racing

24.69

Summit Racing camshaft kit

K1107

Summit Racing

100.95

Summit Racing valvespring kit

174000

Summit Racing

71.95

Summit timing set

G6501

Summit Racing

13.95

Summit stock pushrods

G6400

Summit Racing

26.95

Sealed Power brass freeze plug kit

Z381

Summit Racing

18.95

VHT Chevy orange paint

DE1620

Summit Racing

6.95

GMPP self-align 3/8-inch rocker arms

12495490

Summit Racing

61.95

Edelbrock Vortec Perf. RPM intake

7116

Summit Racing

187.95

Weiand Speed Warrior dual-plane

8501

Summit Racing

209.95*

Holley 750 mech.-secondary carb

0-4779

swap meet

150.00

Oil pan, timing, and valve covers

used

swap meet

10.00

Used 15/8-inch headers

used

swap meet

50.00

HEI distributor

used

boneyard

25.00

Summit Racing plug wires

868836

Summit Racing

29.95

Bosch Super + spark plugs

7975

Auto Zone

15.92

Wix oil filter

51069

Summit Racing

5.95

Comp Cams break-in oil, 10W-30

1590

Summit Racing

26.25

PARTS SUBTOTAL

$1,792.86

Comp nitrided Thumpr hyd. cam

12-601-20

Summit Racing

274.95*

Comp Pro Magnum hydraulic lifters

858-16

Summit Racing

94.95*

Comp oil, semisynthetic, 10W-30, 5-qt

1594

Summit Racing

39.75*

Comp break-in lubricant

159

Summit Racing

10.95*

MACHINE WORK OPERATIONS

Cost

Hot-tank block

$60.00

Install cam bearings

50.00

Resize big ends of rods

100.00

Torque-plate-hone cylinders

190.00

Grind crankshaft

240.00

Machine valveguides and reassemble

80.00

MACHINE TOTAL:

$720.00

GRAND TOTAL

$2,512.86

*Not included in Grand Total

While this total may seem expensive, it is a true accounting of all the costs incurred including carb, ignition, and headers. Most "budget" magazine stories from our competitors rarely include these numbers. The critical point that should be emphasized is that investing a few more dollars for good oversize pistons would have created a very solid motor that would make a ton more power and could be counted on to survive for years. The durability of this "shortcut" engine is debatable, at best, and its lack of compression also will make it a fuel guzzler.