We've covered many engine stories in these pages, a number of them with the respected Sacramento, California, engine shop, Smeding Performance. Since the number of actual "steps" involved in putting a precision engine together could fill most of a magazine, we take a plethora of photos, but for concerns of page usage, we only use selected ones in a story. If you're like Editor Brennan, you have read dozens of engine stories over the years and you're tired of all those "stock" photos. In this buildup, we've attempted to cover some unique aspects of this particular engine, and a few other tips you may have never seen.

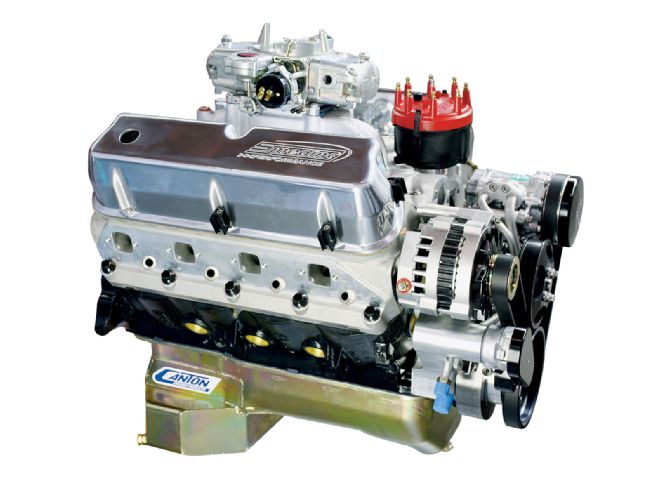

Here's a Blue Oval guy's dream: big-block 427 power in Windsor packaging! Although the beefy Dart SHP block weighs more than a stock thin-wall Windsor, we've made up for that with Smeding heads, an Edelbrock intake, and a compact Vintage Air Front Runner, all in aluminum.

Here's a Blue Oval guy's dream: big-block 427 power in Windsor packaging! Although the beefy Dart SHP block weighs more than a stock thin-wall Windsor, we've made up for that with Smeding heads, an Edelbrock intake, and a compact Vintage Air Front Runner, all in aluminum.

Our new Smeding powerplant, now at Cotati Speed Shop (the builders of the '10 Road Tour Shadow Rods XL27 highboy roadster pickup), is a 427ci "small-block" Ford based on an interesting block from Dart Machinery (Troy, Michigan) made for sportsman racers. One of a number of super high-performance (SHP) blocks they make for various Ford and Chevy engines, ours has the basic design of a 351-Windsor engine, but it accepts 351 C-journaled crankshafts and has a tall 9 1/2-inch deck height (same as a 351-W, but bigger than the 289-302s) well-suited to stroker applications like ours. While Ford was at the cutting edge of modern engine design when they came out with the lightweight, thinwall casting technique for their new small-block Ford V-8s in 1962, the rapid development of performance and racing applications in the intervening years have plumbed the weaknesses of the design for competition purposes. The Siamese-bore (no space between the bores makes the block much stronger) Dart cylinder walls are 1/4-inch thick, the main webs are beefed, billet four-bolt main caps are fitted for the center three main bearings, the deck is 0.675-inch thick, and in all respects it's bulletproof for usage up to 600 hp.

Why the Cleveland main journal size? Of the millions of 260-289-302-Windsor engines out there, the crankshaft mains are 2.2486-inch diameter, while the 351-W mains were 3.00-inch. The 351-C mains are 2.749-inch, beefier than the smaller Windsor cranks, but with less bearing speed than the 351-W. A variety of aftermarket performance crankshafts are available in the Cleveland format, and racers and engine builders like the reduced drag of the smaller bearing size. Reducing friction in an engine adds horsepower, and that's something our new Smeding engine has in spades. Like the sound of 462 hp? Well, that's cool, but this 427 also exhibits a very broad torque curve (the torque peak was 529 lb-ft), but the average torque over the range of all dyno speeds from 2,500-5,500 rpm was a tick over 500 lb-ft. Better buy stock in a tire company!

Unless you have Ben Smeding's experience of many years of building engines, you can't just flip through a performance catalog and select your valvetrain, heads, pistons, and other critical components and throw them all together expecting optimal results. There's a science to performance engines; all the components must work together. Smeding takes the intended use of the customer into consideration and matches all the right parts with an eye to that specific application. Smeding Performance engines are built not just from new premium blocks, but Smeding has picked the cream of the aftermarket for the internal and external pieces. In some cases, when he couldn't find the exact part he wanted, he has companies make heads, crankshafts, rods, and pistons to his specs. Having a dyno on hand to test each engine ensures that everything in the combination is simpatico.

It should be understood that a racing block such as the Dart we're using isn't ready to use as shipped, but rather is in the ready state for a professional engine builder to bore and hone for his preferences. There are gallery plugs to be installed, threaded holes to be cleaned for precise torque readings, and other minor details to be addressed. The central piece in the Dart block for our 427 is a 4340 forged-steel crankshaft with radiused journals and a 4-inch stroke. You may have seen in other stroker-engine stories how a stock Ford or Chevy block often has to be ground for rod-to-block-skirt clearance, but starting with a professional racing block makes the procedure minimal. One other aspect of our crankshaft is that it is internally balanced, rather that the external balance of most production engines. With the latter design, flywheels, driveplates, and crankshaft dampers must have offset weights to balance the dynamics of the rotating assembly, and this is fine for stock or mildly modified engines. All the small-block Fords were balanced this way because Ford's weight-trimming goal precluded allowing enough space for the larger counterweights of an internal-balance crankshaft. Most racing engines use the internal balancing system, due to the higher power levels and running at higher rpm.

Complementing our stout crankshaft are 6.2-inch-long, I-beam aftermarket rods of 4130 forged steel. The forged pistons are made to Smeding's specifications with an interesting dome profile. There are reliefs for the valves, of course, but the dome is "reversed," with a "squish" area inboard of the valves that is designed for a quicker chamber burn, which translates into more efficiency with less ignition timing for a cooler running engine. In our application, the compression ratio is 9.8:1, high enough to take advantage of the camshaft profile but useable with pump gasoline in our hot rod.

Choosing the right camshaft could be the toughest call for the rodder building his own engine at home. All the sexy names and purple prose for marketing cams can make you believe that every one of them is the right grind for your application. As with carburetion, most rodders tend to go too far on camshaft timing, and wind up killing their low-end power and corrupting the idle quality. We all know it's a bear to finish a car completely, then have to work around painted and detailed parts to r'n'r a camshaft. It's a situation that prompts some rodders to leave the impractical bumpstick in place and just live with the drawbacks. Despite the power parts in our 427, it's not a racing engine. Smeding Performance has its own profiles; in this case the hydraulic roller cam's specs are: 0.508-inch intake lift, 0.532-inch exhaust lift, and duration (at 0.050-inch lift) of 222 degrees on the intake and 232 degrees on the exhaust. "Most engines like a little more timing on the exhausts", says Smeding, "and that helps the STREET RODDER 427 achieve such a flat torque curve."

Our Dart Machinery sportsman racing block has a number of performance features, including a main-bearing priority in the redesigned oiling system, thick walls and deck, plus compatibility with a number of available aftermarket stroker crankshafts.

Our Dart Machinery sportsman racing block has a number of performance features, including a main-bearing priority in the redesigned oiling system, thick walls and deck, plus compatibility with a number of available aftermarket stroker crankshafts.

Atop our mighty Smeding Performance short-block ride a pair of heavy-breathing Smeding aluminum heads, the first ones made (and now available for sale) fitted with stainless steel 2.02-inch intake valves and 1.60-inch exhaust. The chamber volume is 60 cc, and the healthy intake ports have a 180cc volume. The heads were installed with multi-layer Cometic head gaskets; they're not cheap, but well worth it for a good seal on a high-performance motor like ours that will pile on the miles to all the events next summer. Windsor engines generally have 7/16-inch headbolts, except for the 351-Ws, which had stronger 1/2-inch bolts. Smeding uses ARP head bolts. Dart's SHP blocks have blind holes for the bolts (they do not go into the water jacket).

The SHP blocks do not have a provision for an oil dipstick, so if you plan on a common front sump-style Ford oil pan, you can use a Ford 351-W front cover that has the provision for the dipstick in it. If you want a rear sump pan, it should be one with the dipstick provision in it, as was the case with our 7-quart Canton pan. Vintage Air has an optional item for applications using their Front Runner accessory mounting system, a stainless-steel dipstick tube and dipstick that fits the right side of their forged aluminum front cover for front sump pans.

The finishing touches that completed our 427 were the installation of the Vintage Air Front Runner aluminum front cover that mounts the water pump and puts the alternator and A/C compressor down low and tucked in, all driven by one serpentine accessory belt. After the neutral-balance (no counterweight) crank damper was installed, the topside was closed up with Edelbrock's Performer RPM AirGap intake manifold and a 750-cfm Barry Grant Demon four-barrel with vacuum secondaries and electric choke.

At this point we had what looked like a runner, but as most of us know, "it's the little details" that delay that exciting initial startup-like adjusting the lifters before mounting the valve covers, timing the distributor and routing the new plug wires, adding oil and an oil filter (filled with oil), making electrical and water connections, coolant temperature sender, power to the choke and ignition, dyno header hookup, and installing plugs in the block drain holes.

At Smeding Performance they build, dyno, and ship engines every day, so they have these items down to a routine, like a pilot's checklist. They don't ship engines with oil in them, but you'd be shocked to know how many customers, in the days before Smeding had his own dyno, have started a brand-new expensive engine without putting oil in it, even with the engine clearly marked "NO OIL"! The dyno time is a controlled environment for engine break-in and tuning, plus counterchecks that everything is working to Smeding's satisfaction, and when they drain the dyno oil and attach the oil warning sticker, they know the customer can't blame a faulty oil pump or some other mechanical problem if it doesn't work at his house. The lesson for amateur engine guys is keep your head clear, don't rush, use a checklist, and read the instructions that accompany each Smeding engine.

When Zane Cullen finishes the '10 AMSOIL/STREET RODDER Road Tour XL27 roadster pickup, and veteran pilot Jerry Dixey once more has the dream job of commanding the wheel of yet another outstanding example of street rodding showcasing the products of our industry, we'll be envying his first turn of the key and the drive around the block. There will be no surprises except good ones, like the sound and power of a 427 Ford that easily fits a hot rod and delivers plenty of "romp when you stomp"!