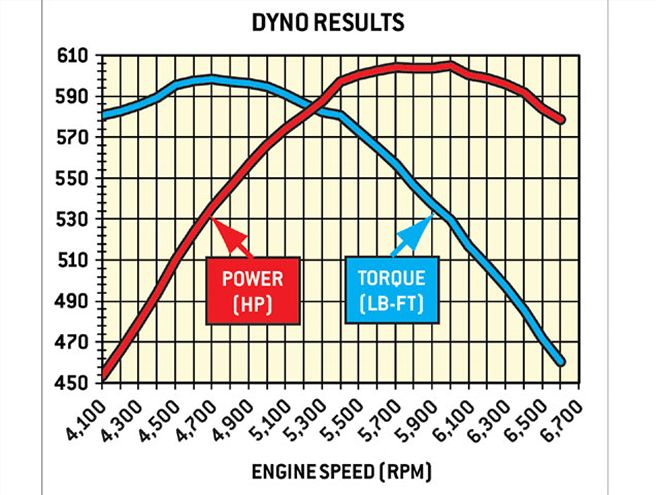

Breeding a bigger Cobra: Actually displacing 463.2 ci, Joe Sherman's 465 was assembled from a 428 block, a Scat rotating assembly, a Comp Cams solid roller cam and valvetrain, and Edelbrock aluminum heads. Running on 91-octane unleaded, the FE motor made 605 hp at 6,000 rpm and 598 lb-ft at 4,700.

Breeding a bigger Cobra: Actually displacing 463.2 ci, Joe Sherman's 465 was assembled from a 428 block, a Scat rotating assembly, a Comp Cams solid roller cam and valvetrain, and Edelbrock aluminum heads. Running on 91-octane unleaded, the FE motor made 605 hp at 6,000 rpm and 598 lb-ft at 4,700.

Joe Sherman is primarily known as a builder of stout stroker small-block Chevy and Ford engines that make big power at a reasonable price. Recently, a longtime Sherman customer asked him to apply some of his magic to the venerable Ford 428 Cobra Jet, a member of Ford's long-out-of-production FE big-block family. Thanks to widely available Edelbrock aluminum FE cylinder heads and affordable Scat stroker rotating assembly kits, Sherman reports things are looking up for the old FE, which is still coveted by enthusiasts restoring old '60s-era muscle cars or building Cobra kit cars. Although affordable production blocks are becoming hard to find, the end result is, Sherman reports, an engine that's "competitive to a 440 Chrysler. It's no 454 Chevy, but it's definitely not a slug, either." Applying modern tech to Ford's old warhorse, Sherman came up with a 465ci engine that has a torque curve broader than the Mississippi River and more power than a speeding locomotive. Even with its 11:1 compression ratio, the mechanical roller-cammed engine is happy on 91-octane gas. As Sherman puts it, "This engine is high-performance fun, the ultimate street/strip engine in a lightweight car like my customer's Cobra."

The undersquare torquer made more than 500 lb-ft from 4,100 to 6,200 rpm, more than 500 hp starting at 4,500 rpm, and more than 600 hp from 5,500 to 6,100. Still, Sherman feels there's even more potential left in the old dinosaur. At the cost of streetability, a 20-degree-bigger cam (about 270 to 275 degrees at 0.050) would raise the power peak past 6,500 rpm.

The undersquare torquer made more than 500 lb-ft from 4,100 to 6,200 rpm, more than 500 hp starting at 4,500 rpm, and more than 600 hp from 5,500 to 6,100. Still, Sherman feels there's even more potential left in the old dinosaur. At the cost of streetability, a 20-degree-bigger cam (about 270 to 275 degrees at 0.050) would raise the power peak past 6,500 rpm.

Rotating AssemblyIn a perfect world, you'd want to start with a big 4.23-inch-bore 427 side-oiler block, but they're impossible to find these days. Even 428 blocks (4.13-inch bore size) are becoming scarce; figure on paying upwards of $1,100 for a good used core. This build uses a thin-wall 428 block bored 0.035 inch oversize to 4.165 inches so it can use readily available piston rings. If you can't find a 428, most 390s can be bored out to the 428 bore size.

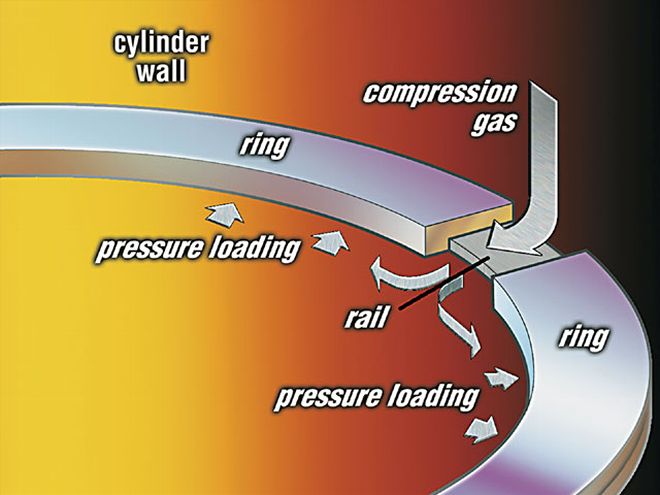

Total Seal's gapless top ring comprises an L-shaped pressure ring that's supported by a thin support rail. Compression gas is deflected by the gapless rail into the piston groove, pressure-loading the ring during the four-stroke cycle. The rail closes off the combustion leak path created by the ring's normal gap, virtually eliminating blow-by.Illustration: Total Seal

Total Seal's gapless top ring comprises an L-shaped pressure ring that's supported by a thin support rail. Compression gas is deflected by the gapless rail into the piston groove, pressure-loading the ring during the four-stroke cycle. The rail closes off the combustion leak path created by the ring's normal gap, virtually eliminating blow-by.Illustration: Total Seal

With Scat's 4.250-inch lightweight stroker cast crank, this brings the engine out to 463.2 ci, although it's advertised as a 465. Scat supplied the crank as part of a complete rotating assembly kit that included 6.70-inch center-to-center rods, forged flat-top pistons, piston rings, and main and rod bearings. Sherman substituted a Total Seal gapless ring set for the rings normally supplied in Scat's kit. The trick set includes a 1/16-inch multipiece gapless top ring, a 1/16-inch Napier second ring that combines very low friction with superior oil-scraping capability, and a 3/16-inch standard-tension oil ring. Lately, Sherman has been using Napier rings on just about all his builds. "It's worth 10 to 20 hp," he says.

Gapless rings require an extremely smooth bore hone for proper seating (about a 400-grit stone on the Sunnen hone), plus special Total Seal break-in powdered lubricant . . . but the added effort is well worth it: "The motor spins with less than 20 lb-ft effort," Sherman says. "Normally, it takes around 40 lb-ft."

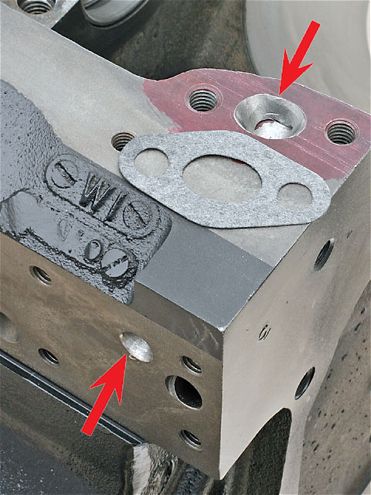

Enlarge the 3/8-inch oil-pump-to-filter passage (arrows) to 7/16 inch, then chamfer the opening to match the gasket hole.

Enlarge the 3/8-inch oil-pump-to-filter passage (arrows) to 7/16 inch, then chamfer the opening to match the gasket hole.

The overbore, final hone, decking, align-honing, and engine balancing were all performed by Ultra Performance Machine, Sherman's preferred machinists. Interestingly, the final hone was accomplished without a torque plate: With only four head bolts per cylinder, on an FE, the bolt spacing is sufficiently far from the cylinder bores that Sherman feels there is little, if any, induced bore distortion from tightening the head bolts.

ARP supplied the head bolts and other critical fasteners, while Fel-Pro forked over all the gaskets except for the Milodon oil pan (which came with its own gasket) and the Cometic 0.051-inch compressed-thickness MLS head gaskets. Thicker than Fel-Pro's offering, Cometic's design is needed to achieve the proper piston-to-head clearance with this build's deck height.

OilingOne area that needs help on the FE is the oiling system. Ford corrected the deficiencies in the side-oiler 427 blocks, but most of us aren't fortunate enough to have one of these rarities. All sorts of mods have been promulgated to try and fix the FE's oiling, but Sherman's are relatively straightforward and effective, as shown in the photos. He also installed a Ford oil filter adapter with larger internal passages originally used on side-oiler engines and later offered as a standard service replacement part for all FE engines (Ford PN COAZ-6881-A, discontinued; Dove Performance Parts offers an equivalent repro part). Sherman installed a high-volume oil pump, but the standard unit works OK, too. Milodon's 5/8-inch pickup (PN 18515) works with its Cobra road race pan, as does its beefy 7/16-inch heavy-duty driveshaft (PN 22550).

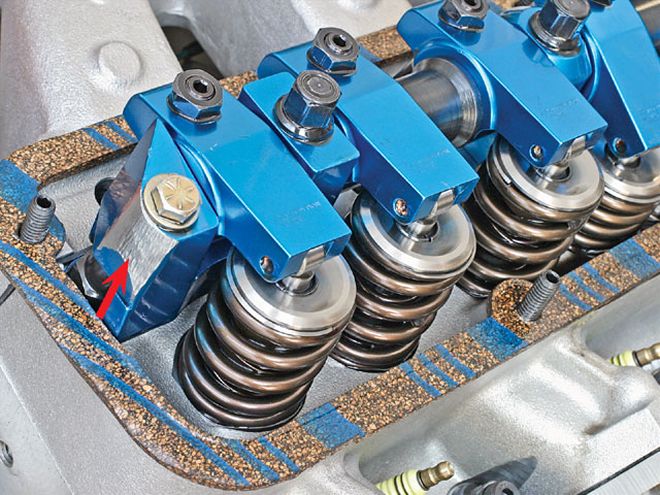

Cam And ValvetrainComp Cams supplied the solid roller cam and major valvetrain parts with an eye toward durability and a broad power range. This includes the fairly pricey shaft rocker arm kit. FE heads-both stockers as well as aftermarket versions like Edelbrock's-are machined for a shaft-mounted valvetrain, but even the rare OE adjustable version isn't up to a mechanical roller's rigors. Although Comp claims a 1.73:1 rocker arm ratio for its setup, during trial assembly Sherman discovered the effective ratio is a whopping 1.93:1. This required a valvespring swap to prevent coil-bind, custom-length pushrods, and elongating the intake manifold's pushrod slots for clearance with the altered valvetrain geometry. (On an FE, the pushrods run through the intake.) FE engines oil through the heads, so be sure any replacement pushrods have solid tips.

Cylinder HeadsThis engine uses Edelbrock's popular Performer RPM FE cylinder heads. Clearly superior to any original production FE low-riser head, they're available bare or fully assembled at a reasonable price. Good as they are, Sherman tuned them up even more.

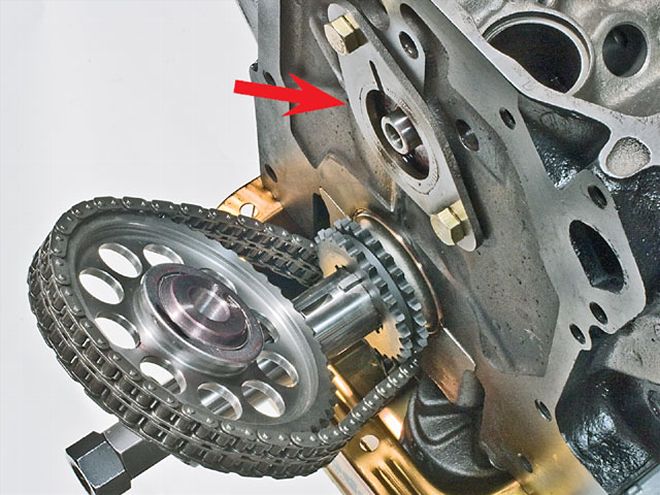

The Comp nine-way-adjustable billet double-roller timing set (PN 7108) includes a roller thrust bearing for reduced friction. The crank sprocket is adjustable in 2-degree increments and offers an 8-degree maximum advance/retard. Note the stock Ford thrust bearing (arrow)-no cam walk problems or spark scatter here.

The Comp nine-way-adjustable billet double-roller timing set (PN 7108) includes a roller thrust bearing for reduced friction. The crank sprocket is adjustable in 2-degree increments and offers an 8-degree maximum advance/retard. Note the stock Ford thrust bearing (arrow)-no cam walk problems or spark scatter here.

Induction, Ignition, ExhaustFeeding the Edelbrock heads is an 850-cfm Demon and Edelbrock Victor intake (PN 2936). The ignition is all MSD, while exhaust is handled by a trick set of custom-stepped Jardine headers pushing the gas through a set of MagnaFlow mufflers. Theoretically, the stepped headers broaden the overall torque curve.

Critical SpecsExcept as noted, all dimensions are in linear inches. For a complete list of part numbers, surf to hotrod.com.Engine type: Ford FE big-block V-8Engine builder: Joe Sherman RacingMachinist: Ultra Performance MachineEstimated build cost: $14,000Max torque: 598.4 lb-ft at 4,700 rpmMax power: 604.8 hp at 6,000 rpmFuel: Chevron 91-octane unleadedTotal timing: 40 degreesJetting: 82 primary/90 secondarySpark plugs: NGK R5672-7, 0.055 gap

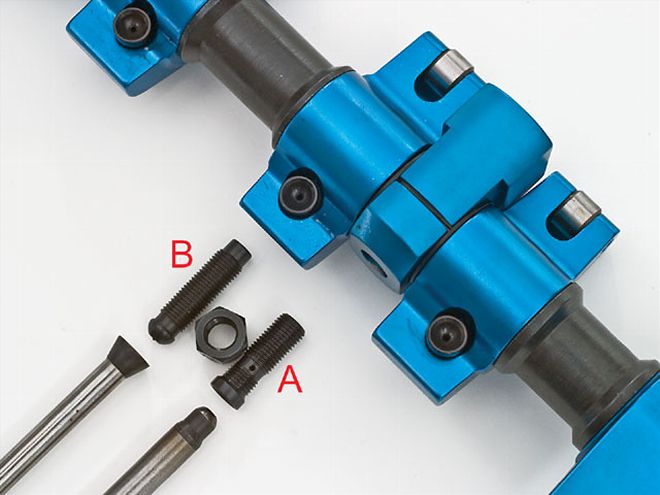

Comp 7000-series aluminum shaft rockers have 1.200-inch-wide rocker bodies. The shaft has special end stands for high-rpm valvetrain stability, plus top and bottom oil holes for better rocker lubrication. T&D adjusting screws (A, compared with standard Comp screw, B) allow using conventionally tipped pushrods.

Comp 7000-series aluminum shaft rockers have 1.200-inch-wide rocker bodies. The shaft has special end stands for high-rpm valvetrain stability, plus top and bottom oil holes for better rocker lubrication. T&D adjusting screws (A, compared with standard Comp screw, B) allow using conventionally tipped pushrods.

Short-BlockAdvertised displacement: 465 ciActual displacement: 463.2 ciBore x stroke: 4.165 x 4.25Compression ratio: 11.12:1Main bearing clearance: 0.0025Crankshaft thrust clearance: 0.007Rod bearing clearance: 0.0028Rod side clearance: 0.020Rod center-to-center: 6.700 Rod/stroke ratio: 1.58:1Crank centerline-to-deck: 10.170Piston-to-bore clearance: 0.0045Piston compression distance: 1.350Piston deck height: -0.005 (above)Piston dish volume: -6 ccHead gasket compressed volume: 11.9 ccPiston ring gap, first groove: 0.027 (step-gap)Piston ring gap, second groove: 0.028Piston ring gap, oil groove support rail: 0.025Piston-to-head: 0.046Piston-to-valve (intake/exhaust): 0.090/0.120

CamshaftType: Mechanical rollerPart No.: Comp Cams PN 33-999-3Grind No.: FB 4830B/2518B SR 110.00.020 duration (intake/exhaust): 283 degrees/292 degrees0.050 duration (intake/exhaust): 255 degrees/262 degreesLobe centerline (intake/exhaust): 106 degrees/114 degreesLobe separation: 110 degreesLobe lift (intake/exhaust): 0.389/0.381Effective rocker ratio: 1.93:1Valve lift (intake/exhaust): 0.751/0.735 (0 lash)Valve adjustment (intake/exhaust): 0.014/0.014

Sherman had to grind the rocker arm stands (arrow) and corresponding area on Edelbrock's cast-aluminum valve covers for clearance. Comp Cams dual (with damper) springs are installed over locators with plus-0.050-inch offset keys and titanium retainers.

Sherman had to grind the rocker arm stands (arrow) and corresponding area on Edelbrock's cast-aluminum valve covers for clearance. Comp Cams dual (with damper) springs are installed over locators with plus-0.050-inch offset keys and titanium retainers.

ValvespringsPart No.: Comp PN 26099Type: Dual with damperID x OD: 0.769 x 1.625Rate: 561 lb/inSeat pressure: 273 lbs at 2.000Open pressure: 693 lbs at 1.250Coil-bind: 1.184

Cylinder HeadsPart No.: Edelbrock PN 60059 (modified)Valve sizes (intake/exhaust): 2.15/1.65Port volume (intake/exhaust): 170/125 ccCombustion chamber volume: 77 ccIntake flow (28in H2O): 302 cfm at 0.700Exhaust flow (28in H2O): 217 cfm at 0.700

Critical Tightening ValuesWith ARP assembly lube:ARP capscrews in Scat rods: 70 ft-lbARP head and main bolts: 105 ft-lbRocker shaft retention bolts: 45 ft-lb

Sherman-installed Ferrea 6000-series stainless 2.15/1.655-inch valves are used in place of Edelbrock's standard 2.09/1.66 valves. Ultra Performance Machine also reworked Edelbrock's 30-degree intake seats to 45 degrees. "On low-lift cams up to 0.300 lift, a 30-degree seat may be better," Sherman says. "But above that, 45 degrees is superior."

HEAD FLOW: STOCK VS. EDELBROCK CFM at 28 inches of water on Joe Sherman's SuperFlow bench. HEAD→ OE IRON 428 {{{CJ}}} EDELBROCK EDELBROCK MODS→ MILDLY PORTED AS-DELIVERED MILDLY PORTED VALVE→ 2.09'' 1.66'' 2.09'' 1.66'' 2.15'' 1.66'' LIFT ↓ INT. EXH. INT. EXH. INT. EXH. 0.{{{100}}}'' 78 54 75 55 75 60 0.{{{200}}}'' 136 96 146 108 142 120 0.{{{300}}}'' 185 128 182 138 201 158 0.400'' 224 163 217 159 251 177 0.500'' 230 180 243 168 280 188 0.{{{600}}}'' 239 188 258 191 293 206 0.700'' 266 197 302 217

Sherman-installed Ferrea 6000-series stainless 2.15/1.655-inch valves are used in place of Edelbrock's standard 2.09/1.66 valves. Ultra Performance Machine also reworked Edelbrock's 30-degree intake seats to 45 degrees. "On low-lift cams up to 0.300 lift, a 30-degree seat may be better," Sherman says. "But above that, 45 degrees is superior."

HEAD FLOW: STOCK VS. EDELBROCK CFM at 28 inches of water on Joe Sherman's SuperFlow bench. HEAD→ OE IRON 428 {{{CJ}}} EDELBROCK EDELBROCK MODS→ MILDLY PORTED AS-DELIVERED MILDLY PORTED VALVE→ 2.09'' 1.66'' 2.09'' 1.66'' 2.15'' 1.66'' LIFT ↓ INT. EXH. INT. EXH. INT. EXH. 0.{{{100}}}'' 78 54 75 55 75 60 0.{{{200}}}'' 136 96 146 108 142 120 0.{{{300}}}'' 185 128 182 138 201 158 0.400'' 224 163 217 159 251 177 0.500'' 230 180 243 168 280 188 0.{{{600}}}'' 239 188 258 191 293 206 0.700'' 266 197 302 217