What would fuel injection be without a computer controlling all its functions? Less powerful? Sure. Less efficient? Certainly. A heck of a lot more popular? We think so. We'd venture to say that most gearheads, ourselves included, are naturally wary of trusting a mysterious "black box" to control fuel and spark inside a several thousand dollar engine. Carburetors and distributors at least look the part. A computer controller doesn't have the familiar dichromate finish of a Holley 4150. You can't blip the throttle and check the pump shot. There are no jets or metering rods to play with. Heck, most ECUs aren't even mounted in the engine compartment.

But we have a theory about modern technology. It's almost always developed to simplify your life, if you're open-minded enough to embrace it. Thinking about all the different scenarios your engine sees--idling in traffic, wide-open at six-grand through the traps, cruising at 75 in the fast lane--it's an engineering marvel that a carb works at all. Most out-of-the-box carbs will usually work well enough to putt around town before any tuning, but if you're chasing down every last 1/100 second of e.t., you'll have a pretty big chunk of time and frustration invested in perfecting every last passageway in that carb. Makes you wish you could just tell that carb how much fuel you wanted, when you wanted it. And while you're at it, just tell the weights and springs in that distributor to take out a few degrees when the boost comes on.

Common sense suggests that driving your car on the street requires a more versatile fuel system than you'd need to run a quarter-mile down the track. Besides continuously metering air and fuel, a street induction system must provide decent idle quality and fuel enrichment on demand, and be able to fire and run the engine on a cold winter morning. Most street carburetors can meet these basic needs using separate subsystems--internal enrichment and idle circuits, and a choke. It's hard to believe, but EFI systems are less complex and don't need these extra additions to provide the same (or better) level of driveability. Even better, most EFI kits control ignition timing electronically, so you can add or subtract a few degrees of advance to run safely on the edge of detonation. The reasons stem from the most basic principles of their operation.

How a Carb Works

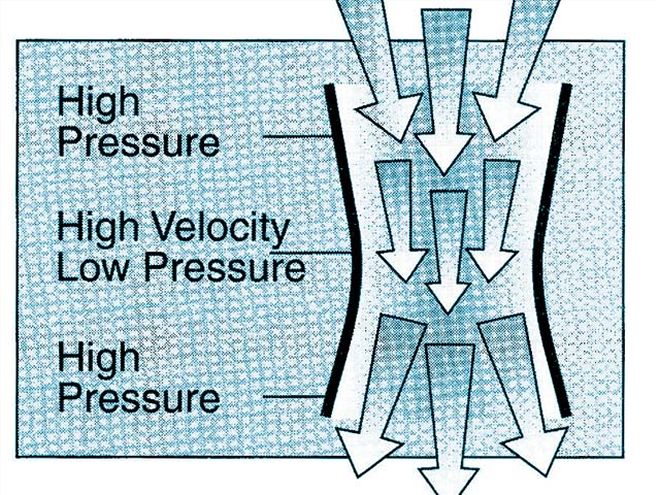

A carburetor takes advantage of the venturi effect to meter a certain fixed ratio of fuel and air into the engine. A sharp "step" in each throttle bore accelerates the incoming air stream, increasing its velocity and creating a region of lower pressure under the fuel booster. Often an additional low-pressure area is created in a venturi-shaped booster. These combined pressure drops draw small droplets of emulsified fuel from small orifices (discharge nozzles) inside the boosters and into the air stream. The size of the main jets controls the amount of fuel that's drawn out of the discharge nozzles. Dip into the throttle a bit more, and a bit more fuel gets drawn from the discharge nozzles, into the air stream, and down the intake runners, where the mixture tumbles and mixes together until, ideally, everything is well mixed, or atomized. Then it's drawn into the cylinders, compressed, and fired.

Now we've got the most bare-bones of carburetors that mixes a certain amount of fuel for a certain amount of air we allow to pass through the Venturis, giving us a constant air/fuel ratio. If we change the main jets, the mixture will become richer or leaner--but it'll stay richer or leaner across the entire rpm range. If you need to vary the air/fuel ratio for economical cruising (leaner) or richen it for maximum power at wide-open throttle, this system won't do anything for you. In fact, the main metering system won't even allow the motor to idle because the pressure drop (or "signal") isn't strong enough to pull fuel from the boosters at low rpm. This is why a modern carb has a separate idle circuit, one or more enrichment circuits, and a choke to keep the mixture artificially rich on cold days before the motor's hot enough to atomize the mixture nicely.

How EFI Works

A modern multiport EFI system works differently than a carburetor, but it"s still bolted to the same motor and installed in the same car, so it must provide at least the same level of functionality. No venturis here--fuel isn"t introduced into the engine until the injectors spray it into the base of the intake runners, so the only thing that"s mechanically metered is the air that"s sucked through the throttle body. Since the mixture of air and fuel can"t tumble around inside the intake runners, the injectors spray a fine mist of fuel at high pressure, which "forces" it to mix almost instantly with the metered air. Changing the air/fuel ratio is simply accomplished by varying the amount of time that the injectors are spraying fuel (usually measured in pulsewidth, the number of milliseconds each injector is turned on). You can probably imagine how a choke, idle, or enrichment circuit can be designed into this system. It"s easily done by increasing (or decreasing) the pulsewidth to richen (or lean out) the mixture whenever it"s needed. It sounds simple because it is! So let"s break down some of the basic functions of a carburetor and see how an EFI system accomplishes the same tasks with the aid of a computer.

Main Metering Circuit

A carburetor"s main metering circuit operates solely on the venturi principle, which by itself would fit our needs perfectly if a car ran only at a constant load and rpm, such as up a slight hill in First gear. But in the real world, engine load changes, and selecting the proper main jet size is only the first step in creating a well-tuned street machine. Carbs keep the engine properly fueled over a range of conditions by sensing vacuum (engine load) and kicking in additional fuel via its enrichment circuits, but that"s a topic we will address a little later. Modern EFI systems use "maps"--a table of numbers corresponding to certain parameters (i.e., rpm) saved in the onboard computer to tell the injectors how much fuel is needed at any conceivable operating point. The base fuel map tells the injectors how much fuel to spray at a certain rpm for a given engine load. This isn"t a direct analogy to a carburetor"s main metering circuit because it recognizes that an engine under heavy load needs more fuel (enrichment) than a lightly loaded engine, so it"s already a little smarter than our "bare-bones" carb. The idea is to match the perfect injector pulsewidth across a full range of steady-state rpm and load (manifold pressure or vacuum) to keep the motor at a happy air/fuel ratio across the board. Steady-state simply means that the engine is allowed to settle out and remain at that operating point. Other maps take care of adding or subtracting fuel depending on throttle position and rate of opening, so it"s important that the base map be tuned only after the engine has reached steady-state. After the main fuel map is dialed in, it serves as the "fingerprint" of the motor and shouldn"t be altered unless major changes are made to the combination.

Some EFI systems use volumetric efficiency (VE) as the main variable in the base fuel map. The VE is defined as the maximum amount of air that the engine can theoretically suck into the cylinders, divided by the actual amount of air that the engine ingests. One hundred percent VE means the engine is "perfectly" efficient; forced-induction powerplants often have greater than 100 percent VE as the intake air is pressurized, and would fill a greater volume if allowed to expand at atmospheric pressure. Knowing the VE at various load and rpm points, as well as the injector flow rate, engine displacement, and number of cylinders, the computer calculates the injector pulsewidth needed to supply the right amount of fuel. Using VE instead of pulsewidth can save time if you do an injector swap--you simply type in the new injector flow rate instead of having to change every pulsewidth value across the base fuel map.

Now that the engine is fingerprinted, the EFI computer still needs to know what air/fuel ratio to supply. Most EFI systems enable you to type in the air/fuel required across the usable rpm and load range of the engine. Simply set the WOT area of the map (high load) to around 12.8:1, cruising (low load, moderate rpm) to around 14.5:1 for efficiency, and set the idle around 13.5:1 to keep your eyes from watering at stoplights. More sophisticated EFI systems use feedback from a wide-band oxygen sensor (WBO2), installed at the header collector, to monitor and display the actual air/fuel ratio. The actual versus mapped air/fuel ratio is displayed as a percent correction. Tuning the VE table with a WBO2 is pretty straightforward--change your VE values until the computer correction nears zero. If a standard narrow-band oxygen sensor is used, the computer can only display air/fuel ratios in a narrow range around 14.7:1, so tuning is slightly more difficult. Either way, the benefit of any O2 feedback signal (closed loop) is a huge advantage in tuning and performance.

Choke

Often shed for performance reasons, the choke is still an important part of a street car that"s driven in cold conditions. A simple device, the choke butterfly closes off most of the air from the primaries, creating a rich condition to compensate for poor atomization of the fuel when the engine is still cold to the touch. Choke pull-off is controlled by a manually operated cable, electric resistance, or the heat of the intake manifold, depending on the design.

As you might have guessed, there"s no choke butterfly attached to a multiport EFI throttle body--it"s all done with electronics, and common sense will guide you through. Tweaking the "Cranking Fuel" graph changes how long the injectors stay open, and consequently, how much fuel the engine is fed when you blip the key (pumping the pedal won"t do a damn thing). After the engine fires, you"d like to use up some of that excess cranking fuel before the injectors kick on, so you enter how many revs the engine must turn before the Afterstart enrichment is added. Afterstart enrichment gives the richening effect of the choke, so you open another map and make sure that extra fuel completely dies out by the time the engine warms up.

Conclusion

The bottom line is that EFI systems and carbs all need to do the same things to make an engine run, and once you get past the fear of that little black box, it"s apparent that EFI provides a level of versatility and ease of tuning that even the best carbs can"t touch.

The initial cost is greater, and the learning curve is a bit steeper, but in the end, knowing how EFI works will actually make you a better carb tuner.

Common Misconceptions

We're amazed at the amount of EFI-related misinformation and BS we overhear at car shows, races, and straight from the mouths of "experts." So we told some real experts from FAST, ACCEL, and Holley what we heard and had them set the record straight.

What we hear: "EFI gives way better fuel economy than a carb."

Reality: It depends on how the car is driven. EFI allows more efficient part-throttle cruising, but if you have a street/strip car that's driven hard, don't expect 20 mpg.

What we hear: "Your injectors and throttle body can never be too big."

Reality: If the injectors are too small or too large, the computer will not be able to control them accurately, resulting in poor performance. A big-bore throttle body isn't necessarily a bad thing, but as the butterflies get bigger, that same throttle angle will cause more air to flow, so it may become more difficult to modulate the engine power (especially off-idle).

What we hear: "You need huge fuel lines to support a high-horsepower EFI motor."

Reality: It's usually OK to have an oversized fuel system, but since most modern multiport EFI systems operate at 40-plus psi of fuel pressure, an identically sized line flows a heck of a lot more fuel than in a 6-psi carbureted system. We've seen 1,000-plus-horsepower EFI'd engines happily fed by AN-8 (1⁄2-inch) lines.

What we hear: "You will never be able to tune your EFI without a professional tuner and a dyno."

Reality: Hey, we pulled it off with our Pontiac 455. We're not tuners, and the car's never seen a chassis dyno.

What we hear: "EFI makes more power."

Reality: Remember, EFI is almost infinitely tunable, so you might see more total power across the RPM range of the engine. But don't expect peak power to change much if you decide to shelve that Holley HP carb for a Commander 950 EFI setup.

Enrichment Circuit

When an engine is under heavy load, the carb's main metering system may not be able to supply it with enough fuel. Carb manufacturers have come up with different styles of enrichment circuits, each designed to trim the air/fuel ratio to meet the engine's needs. Each of these enrichment circuits "sees" the engine load as manifold vacuum. Quadrajets and Carter AFB-style carbs use metering rods to restrict the flow of fuel through the main jets. The rods are supported on small springs that hold them away from the orifices in the jets. Under light loads (cruising), engine vacuum pulls the rods into the jet orifices, restricting fuel flow. Under a heavy load, engine vacuum drops, allowing the springs to force the rods away from the jets and allow more fuel to flow through the jets. Swapping in metering rods with different sized tips alters the amount of fuel enrichment. Modular-style Holley and Demon carbs use a power valve to supply more fuel under load. Vacuum holds the valve closed against an internal spring, and when the engine vacuum drops below a certain level, the spring forces the valve open and allows additional fuel to flow. Think of it as a vacuum-controlled jet.

EFI is already a step ahead of the game. The main fuel map accounts for engine load, so the additional fuel that a carb feeds via its load-sensing enrichment circuit is already accounted for. Easy, huh?

Idle Circuit

The venturi effect is nice and predictable, but it won't draw fuel out of the boosters if the pressure drop isn't sufficient. At near-idle speeds, as we'd expect, the main metering circuit is useless. Carburetors use a separate idle circuit that bleeds a small amount of air and fuel, mixed in a specific ratio, below the throttle blades where it's drawn into the engine. Idle screws restrict the amount of mixture that is drawn into the engine (although they have some impact on the idle air/fuel ratio, the range is determined by the size of the idle air bleeds and idle fuel feed restrictions). As the throttle blades are opened, the idle transition slot is "uncovered" and exposed to engine vacuum, drawing more air and fuel until the main metering circuit takes over. Under heavy-right-foot conditions, the accelerator pump shoots a large volume of fuel into the venturis to bridge the time delay until the main metering system takes over.

Whew, that's pretty complicated! Here's the take-home message: the idle air/fuel mixture is fixed unless you modify the idle air bleeds or feed restrictions. The transition circuit is also a done deal for us non-gurus. About all you can easily change is the accelerator pump shot to smooth the off-idle hesitation.

EFI Sensors Explained

A powerful EFI setup needs a mix of sensors to monitor engine conditions and deliver the right amount of fuel and optimal ignition timing. Engine rpm can be read from a factory-style distributor or some type of crank trigger. Other sensors are required to keep tabs on the engine, so we compiled a list of those you're most likely to encounter.

ATS: Air Temperature Sensor. The ATS is calibrated to deliver the temperature of the air entering the engine. It's usually plumbed as close to the throttle body as possible (i.e., at the base of the air cleaner) to give the most accurate temperature reading.

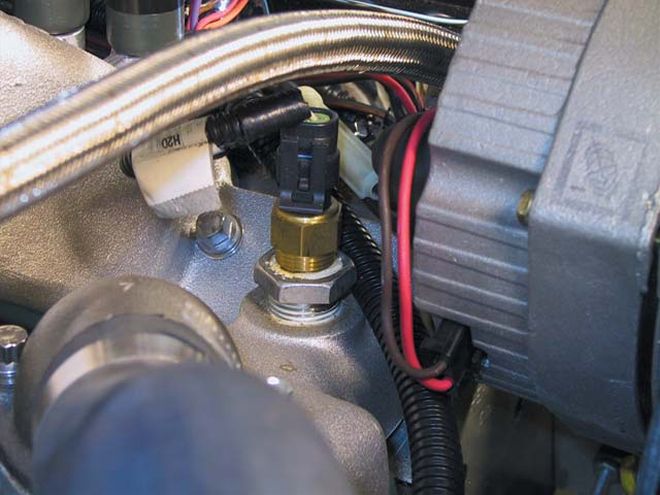

CTS: Coolant Temperature Sensor. The computer has to know the coolant temperature to trim the cold-start and warmup circuits to maintain all-around driveability. The CTS is plumbed into a coolant passage (usually somewhere on the intake manifold in OEM applications).

Knock Sensor: Often mounted directly to the engine block, the knock sensor senses detonation in OEM engines and adjusts ignition timing to stop it. Radical, noisy cam profiles and loud exhaust can "sound" like detonation to a knock sensor, so for that reason, it's usually not present on highly modified engines.

MAF: Mass Air Flow sensor. Plumbed into the intake tract, the MAF sensor tells the computer how much air is entering the engine so it can supply the right amount of fuel. However, most aftermarket EFI systems are speed-density, which means there's no MAF sensor to directly measure the volume of air entering the engine. Instead, the computer uses signals from the TPS and MAP sensor, and knowing the engine rpm, calculates how much air is fed into the motor and supplies it with the right amount of fuel.

MAP: Manifold Absolute Pressure sensor. This sensor is plumbed to a manifold vacuum port and measures the difference between the ambient air pressure and the pressure (or vacuum) inside the intake manifold. A one-bar MAP sensor is designed for normally aspirated engines, while forced-induction motors require either a two-bar (1 to 20-psi max boost) or three-bar (21 to 30-psi max boost) sensor.

O2 Sensor: Oxygen Sensor. Simply put, the O2 sensor compares the amount of oxygen in the exhaust stream with the air outside the engine. It outputs a voltage to the computer--a feedback signal--that the computer uses to trim the amount of fuel depending upon whether the exhaust indicates it's too lean or too rich. A narrow-band oxygen sensor outputs any voltage from 0 to 1 V--a high voltage if the air/fuel ratio is richer than 14.7:1, and a low voltage if it's leaner. It just doesn't do so very accurately or in a linear fashion. A wide-band O2 sensor (WBO2) can sense a range of air/fuel ratios, from a rich 10:1 to a lean 20:1, with reasonable accuracy. Knowing the exact air/fuel ratio makes the WBO2 an immensely useful tuning aid.

<br><br><br><br><br><br>

<br><br><br><br><br><br>

TPS: Throttle Position Sensor. Mechanically coupled to the throttle shaft, the TPS signal is critical to proper idle function and acceleration enrichment.