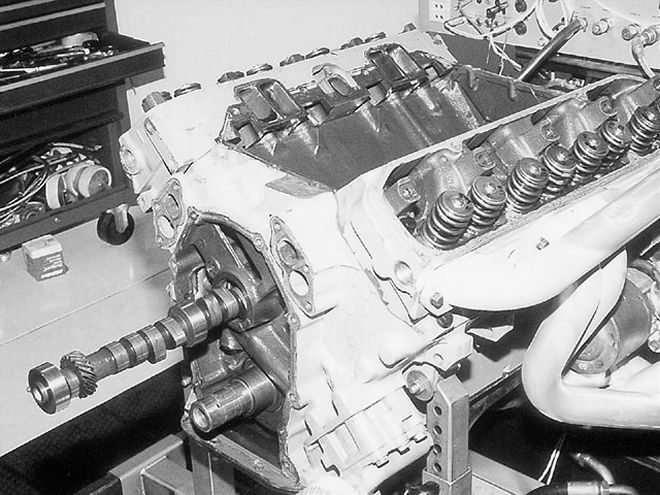

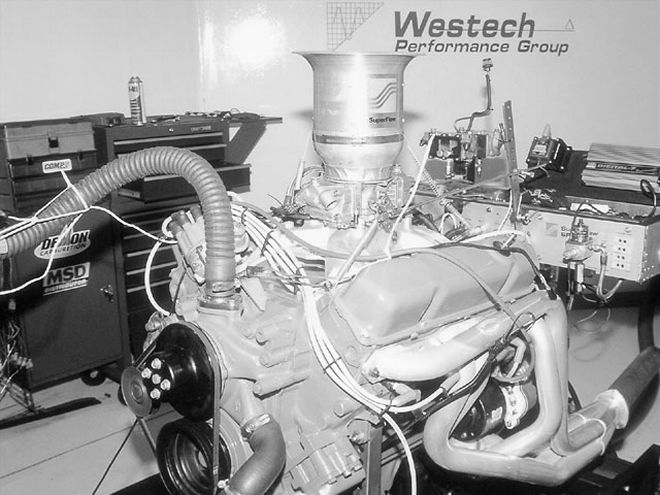

For the baseline run, the engine was mounted to the high-tech Superflow dyno at Westech Performance Group. The engine was built to authentic '69 440 Magnum specs, including valve-jobbed #906 heads and replacement TRW forged pistons.

For the baseline run, the engine was mounted to the high-tech Superflow dyno at Westech Performance Group. The engine was built to authentic '69 440 Magnum specs, including valve-jobbed #906 heads and replacement TRW forged pistons.

Sometimes if you want the facts, you have to go out and get them for yourself. What does it take to get big power from Chrysler's big 440? Rather than just go around and ask, or worse yet, plug some numbers into a computer, getting the real story means burning some gasoline on the dyno and generating the hard info firsthand.

Getting this done requires a suitable test engine and a plan. The most appropriate starting point seemed to be a bone-stock 440 Magnum. After all, it's the legendary performance of the factory package that captivates our interest some thirty years later. In the last issue of Mopar Muscle, the test engine's buildup was detailed. Nothing fancy, just a quality rebuild back to factory '69 440 Magnum specs; right down to an original spec Mopar Performance resto cam and factory iron manifolds. What would it put out?

Though the factory rated the HiPo 440 at 375 hp, this rating, like many of the day, was generally regarded as optimistic. Searching the factory info in some of the old racing bulletins, we find that even Chrysler considered the 375 horsepower rating as excessive. When considering the NHRA factoring in Stock class racing, factory performance engineers made a strong case against the NHRA's Stock horsepower factor at the rated 375; "The original factory rating of 375 was too high...." Further in the Chrysler performance literature, the "Bracket Racer Science" bulletin lists the estimated power production of the stock 440 four barrels at a more conservative 330 hp.

Whatever the stock output, we wanted to know how this basic factory performance package responded to a carefully selected assortment of bolt-on aftermarket performance parts. Rather than just throw random go-fast parts at the stock engine and see what sticks, the approach was to go with proven performance enhancements. All of the modifications planned for the 440 would consist of straight bolt-ons to the basic factory package, just like any enthusiast can perform in their own garage. We ruled out mods that seriously detract from the drivability and usefulness of the engine in a street application. To make the results as representative as possible, none of the components would receive one-off massaging of any kind, as would be typical in an all-out performance build. In other words, the cutters and grinders were left in the toolbox, with the parts just bolted on as-delivered. The specific parts used were selected because they have all been proven to work exceptionally well in the big-block Mopar application.

Phase I: The Baseline

With all the questions surrounding the factory rated output, the stock 440 was taken to Westech Performance Group's Superflow Dyno Facility to put this issue to bed. The test-engine combo as featured last month consisted of a rebuild to stock '69 HiPo specs. The rebuilt engine was dressed out for baseline testing with the factory #178 cast-iron four-barrel intake, an original 440 Magnum application Carter AVS carb, and a set of factory HiPo exhaust manifolds. Attached to the factory exhaust manifolds were a set of reproduction exhaust-head pipes from Year One, which were run full length. The heads were a valve-jobbed set of original 906s, running an original set of valves. Though it's not stock for '69, a factory electronic ignition distributor provided the spark, a concession made for reliability and consistency on the dyno.

Having tested numerous, more radical 440 engine combos over the past year, it was striking just how well behaved the stock 440 Magnum was upon fire-up. After the customary 20 minute cam run-in, we idled down the engine. The stock mill ticked over smoothly, and though there were no mufflers at the ends of the factory headpipes, in the dyno control room the sound was smooth and remarkably quiet. The short overlap of the stock cam had much to do with the docile nature of our stock big-block. We confirmed that the AVS provided an acceptable air/fuel ratio and optimized the ignition timing (37 degrees total) with a few partial pulls. A full pull was run and the baseline numbers were in: 357.8 hp at 4900 rpm, and 463.5 lbs/ft at 3300 rpm. (Tables 1 & 2; Test 1).

Though the output was some 18hp shy of the factory rating, the stock power production was in line with, and even exceeded the realistic consensus. The job from here was to add horsepower to the bottom line. To accomplish this, we took the well-traveled road of improving the induction, exhaust, and finally the camshaft.

Phase II: Carb Capacity

The first step in hot rodding any engine is getting it to breathe. The AVS carb as fitted to the 440 Magnum was a larger unit than used in other Mopar performance-engine applications, but with 440 cubes to feed, would more carb mean more power? The dyno sheet showed 1.4-inches Hg of vacuum being developed at WOT in the manifold by 5400 rpm, suggesting that the carb was becoming a restriction. To see if more carb would benefit even this stock combo, we bolted up a Holley (list #80531) 850-cfm vacuum secondary carb. For purely dyno or drag strip use, a mechanical secondary double-pumper carb is preferred, but for dual-purpose applications the vacuum-secondary unit is often favored. In fact, for years, Chrysler's Direct Connection Program, and later Mopar Performance, recommended an 850 vacuum secondary carb as the best choice on a hot 440.

To fit a Holley carb on the stock iron manifold, a spacer was required to allow the carb linkage to clear. We used a 3/4-inch four-hole spacer matching the four holes in the earlier 440 Magnum intake. Later factory 440 intakes used an open divided carb flange instead of the four-hole type, better suiting an open spacer to gain the required clearance. Getting top power from a vacuum secondary carb requires fine-tuning the secondary opening rate. On the dyno, bogging the engine isn't an issue, since the throttle is pulled wide open, and the engine is allowed to stabilize against the load before the pull is begun. To ensure that the secondary flow was utilized, we fit the secondary opening diaphragm with a light opening spring. On the street or strip, this approach could lead to a bog, meaning that a more progressive opening rate is optimal.

We jetted the big Holley carb using the data from the dyno instrumentation. We let the 440 run, and it produced 366.2 hp at 5100 rpm, and 474.7 lb/ft at 3300 rpm (Tables 1&2; Test III). Swapping to the bigger carb was worth almost 10 hp, and more than 10 lb/ft. Peak horsepower came in 200 rpm higher, confirming that the stock carb's capacity was costing power as the rpm climbed. WOT manifold vacuum dropped to near zero at the base of the carb throughout the test rpm range, showing that the carb no longer restricted airflow. Though the big Holley already showed a significant performance gain, its value will be even more significant as the performance level of the engine is raised with other mods.

Phase III: Exhaustive Research

With the carb adding to the breathing capabilities on the induction side, the next step was to look for breathing improvements on the exhaust side. The 440 HiPo exhaust manifolds on the test 440 were a respectable design as exhaust manifolds go. The factory manifolds have a definite advantage in a street application-not in brute power output, but in quiet, leak-free operation. Move into a set of tube headers, and usually there are some compromises. All headers come with noisier operation and restrict access to engine and chassis components, while some poorly designed types will interfere with items in the engine bay, create rattles, cost ground clearance, and often leak.

That said, many enthusiasts are determined to stick with the factory manifolds, both to avoid the above problems and for the factory looks. Although this engine had original 440 HiPo manifolds, these are getting scarcer by the year. Year One has accurate reproductions of the stock 383/440 high-performance manifolds available, with the bonus of a high-temperature gray cast-iron-colored metallic ceramic coating, which should banish the problem of unsightly, rusty, manifold surfaces. As part of this dyno evaluation, we finished the test manifolds with the coating system to be used on the Year One repops. The durability was excellent under the severe high-heat dyno test environment.

The first exhaust-system upgrade was to swap the stock exhaust manifolds for a set that were Extrude Honed.The Extrude Hone system forces a thick slurry of abrasive paste through a passage under high pressure, which removes material, enlarging the passage and leaving a smooth surface. With the Extrude Honed manifolds in place, the 440 made 367.1 hp at 5100 rpm, and 481.7 lb/ft, a gain at peak of 0.9 hp, and 7 lb/ft (Tables 1&2; Test III). Interestingly, the biggest gains were in torque lower in the rpm range, predominately below the torque peak, with less power added by peak horsepower and beyond. In this application, the Extrude Honed manifolds offered some performance benefit and will hold their clean, detailed appearance over the originals, but are no substitute for a set of tube headers.

Even a cheapo set of headers provides a big increase in power, if the non-stock appearance and other potential compromises are not an issue. To minimize the drawbacks in a tube header, it pays to shop quality. For this test, we used a set of Hooker Competition series 1 7/8-inch street headers #5903, that feature heavier gauge construction than Hooker's race Super Competition series. For street/strip applications, larger tube headers are of questionable benefit, but magnify the fit and access problems. For street and strip use, 1 7/8-inch headers are more than adequate on 440s with 500 or more horsepower and they fit in B- and E-Body chassis (we've run a 440 with 670 hp with the very same pair of 1 7/8-inch headers used in this dyno test). The Hooker headers were bolted to the otherwise unchanged test engine, which promptly responded with 391 hp at 4900 rpm, and 501 lb/ft at 3300 (Tables 1&2; Test IV). The entire torque curve was up handsomely, right from the bottom of our pull to the top. This sweet-idling 440 street engine, with the stock heads, intake, and camshaft, was pulling down some power to be reckoned with! No two ways about it, real headers work.

Phase IV: Intake Invigoration

Though the big Holley 850 carb was one of the first mods made to the 440, up to this point the factory two-plane iron intake had been retained. The factory iron intake is actually a decent piece, especially in terms of low-end torque production. For improved higher rpm breathing and horsepower, a manifold change is always near the top of the list for performance mods. There are a wide range of aftermarket manifolds available for the big-block Mopar, with the Holley Street Dominator being one of the best. The Street Dominator is an older single-plane design, which, unlike some more recent aftermarket intakes, is low enough to fit under most stock hoods. The Street Dominator is a proven power producer, able to support the requirements of engine outputs in the neighborhood of 600 hp.

We pulled the stock 440 Magnum HP cam and swapped in a Comp Xtreme Energy 274 cam.

We pulled the stock 440 Magnum HP cam and swapped in a Comp Xtreme Energy 274 cam.

Swapping intakes on a big-block Mopar is simply a matter of eight bolts, but for maximum output with an aluminum manifold, the heat crossover should also be blocked at this time. Blocking the crossover is easily accomplished by swapping the stock-style bathtub intake gasket for the special Felpro #1215 replacement, which comes with the crossover hole blanked. A word of caution: some intakes with poor fuel distribution will not run properly with the crossover blocked. The crossover heat and subsequent vaporization of the fuel in the intake mask a world of distribution ills found in some manifold designs, though there is a price to be paid in output. The Holley intake works well without heat.

We swapped to the Holley intake, bolting it on without any modifications or port matching. The carburetor was rejetted based on information from the dyno's computer, and the numbers were in: 420.1 hp at 5000 rpm, and 502 lb/ft at 3700 rpm (Tables 1&2; Test V). Peak torque remained nearly identical to the factory intake, but moved to a higher rpm. The real story was in the horsepower gains higher up, bagging a solid 30hp increase on the intake change alone. Once again, the Holley Street Dominator proves its value.

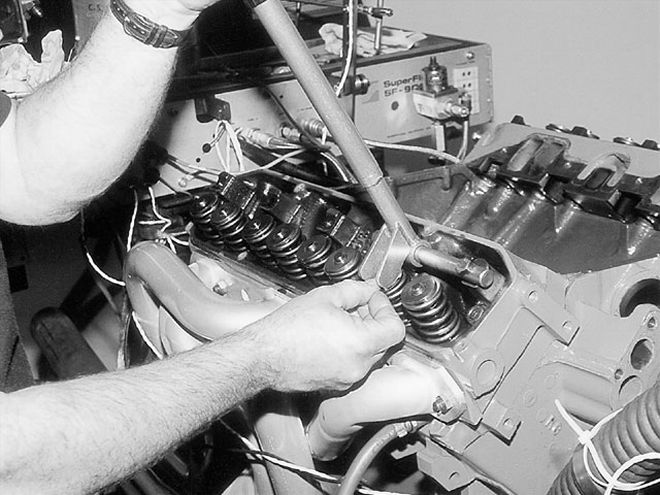

With the cam, a matched set of Comp valve springs replaced the stock factory HiPo units. The Comp valve spring tool makes spring swaps easy.

With the cam, a matched set of Comp valve springs replaced the stock factory HiPo units. The Comp valve spring tool makes spring swaps easy.

Since the Street Dominator is fairly low when compared to some of the more race-oriented single-plane intakes, it sometimes responds to the addition of an open spacer, which increases the plenum volume. We've seen spacers gain as much as 20 hp with the Street Dominator on a roller cammed 440 engine of 600hp or more output. But, would a spacer be beneficial at these more modest street power levels? We changed to an open spacer followed by a dyno pull: no (Tables 1&2; Test VI). At this power level the Holley manifold just didn't need the added volume of a spacer.

Phase V: Cam It

So far, what started out as a stock 440 Magnum saw a bump in power output of about 18 percent with the simplest of bolt-ons: headers, intake, and carb. With the stock heads and cam, the engine was now producing a respectable 420 hp and over 500 lb/ft of torque while retaining the idle quality and smoothness of the stock engine. The next level would have to be a cam change. Since this was ultimately a street combo, there was no use in being too radical. The cam would have to be sufficiently more aggressive to boost output, but not so wild that driveability was compromised.

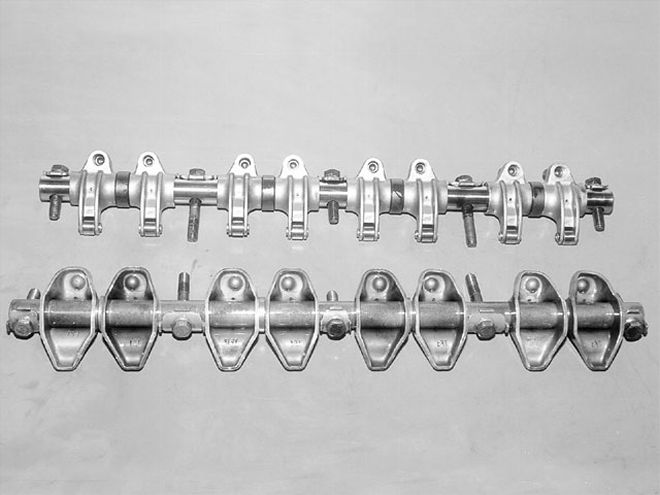

Although the stock hydraulic valvetrain (foreground) could have been retained with this cam, for the ultimate in strength and street reliability, and to allow adjustment for use with anti-pump-up lifters, we went with Comp's #1321 roller rocker kit (background).

Although the stock hydraulic valvetrain (foreground) could have been retained with this cam, for the ultimate in strength and street reliability, and to allow adjustment for use with anti-pump-up lifters, we went with Comp's #1321 roller rocker kit (background).

Competition Cams' line of Xtreme Energy hydraulics have a fairly fast rate of lift for a given duration. The result is better streetability and low-end output for a given top-end performance level. We picked the Comp XE274 cam from the lineup, a good compromise between street friendliness and power output. With specs of 230/236 degrees at 0.050 inches on the intake and exhaust lobes respectively, this Comp stick has the numbers to make some power-but the comparatively short-rated duration of 274/286 (measured at .006-inch tappet rise) helps keep it from being too choppy on the street. We took advantage of the progress made in cam-lobe profiles since the days when the old 440 cam was designed. Lift with the Comp cam was .488 int./.491exh., compared to .450/.458 for the stock cam.

In order to use the new cam, we had to consider the rest of the valvetrain. Comp recommends using premium valvetrain components with their fast-acting Xtreme Energy cams. We ordered the cam and the recommended Comp #911-16 valvesprings as well as a set of 867-16 hydraulic lifters. The #867 lifters are Comp's anti-pump-up offering, designed to run at a minimal (near zero) preload. To take advantage of these lifters, an adjustable valvetrain is required so we ordered Comp's adjustable steel Pro Magnum roller rockers to replace the stock valvetrain. These rockers, which come as a complete kit (with shafts, spacers, and hold-downs) under part #1321-16, are virtually indestructible.

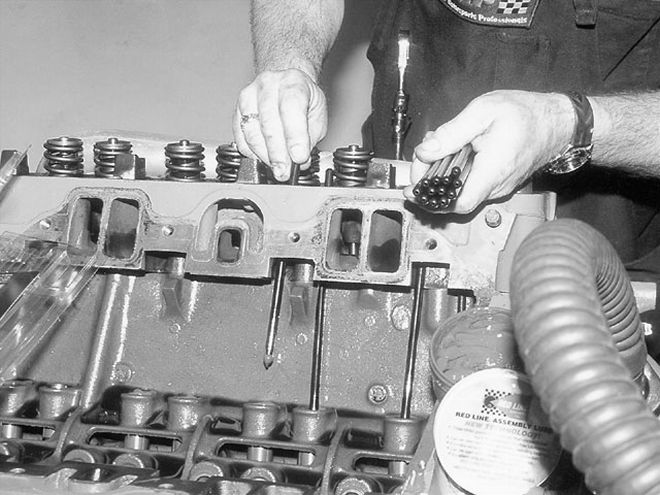

The Comp rockers need a pushrod that places the adjuster at the optimal position for proper oiling. For this engine, the pushrod length required was directly measured, and the appropriate pushrods ordered.

The Comp rockers need a pushrod that places the adjuster at the optimal position for proper oiling. For this engine, the pushrod length required was directly measured, and the appropriate pushrods ordered.

To round out the valvetrain, we ordered a set of Comp's 5/16-inch diameter Hi-Tech pushrods. With the Comp 1321 rockers, the pushrod length is critical, so once the valve adjustment was set, the oil band in the rocker's adjusting screw was centered in the rocker's body. The exact length required for this engine was directly measured, and the pushrods ordered to match. Although for this test we used the premium valvetrain components, this same cam can be run with Comp's standard hydraulic lifter, #822-16, and the stock valvetrain can be retained.

The test 440 was torn down on the dyno, the new cam installed at the recommended 106-degree intake centerline, followed by the new Comp valvetrain. The rockers were adjusted in sequence to provide minimal preload of the lifter's plunger (1/8 turn in from zero, or about .005-.007 inches), and it was ready to run. After the required cam break-in period, the engine settled into an idle. As expected with a hotter cam, the idle was noticeably more lopey than the stock Magnum cam, although the idle quality was acceptable by most standards for a street-performance cam.

Back in action, the 440 pumped out 464 hp and 523 lb/ft. The cam change brought output to another league, but wasn't too radical to make an enjoyable street engine.

Back in action, the 440 pumped out 464 hp and 523 lb/ft. The cam change brought output to another league, but wasn't too radical to make an enjoyable street engine.

The engine was opened up to full throttle against the dyno, and the numbers on this new combo came in strong, with 464.6 hp at 5400 rpm, and a peak torque number of 523 lb/ft at 3800 rpm (Tables 1&2; Test VII). The 440 was up more than 44 hp with nothing more than a change in camshaft and valvetrain. This kind of output from a street combo running through the stock heads, with the stock valves, was phenomenal. The 440 made over 500 lb/ft of torque from 3300-4700 rpm, enough to put the hurt to the stickiest of street meats.

All told, the straightforward bolt-on upgrades to the basic 440 Magnum added nearly 110 hp to the stout factory performance package. That's a 30-percent power boost with an intake, carb, headers, cam, and valvetrain. By using a correctly matched set of aftermarket pieces, the 440 can respond to bolt-ons with a tremendous increase in power.

Dyno HorsepowerRPMTest 1Test 2Test 3Test 4Test 5Test 6Test 72600218.9219.8225.2232.8225.6221.7219.62800239.8{{{240}}}.8246.6253.3246.9242243.13000260.9263.9269.7279.1270.7264.5270.43200282.3287.8292.7303.9296.6292.1301.63400298.5307311.8324.1321.1317.4327.23600313{{{323}}}.4326.4340.8343.8341.4354.63800323.3334337.5355.1362.7360.9378.4{{{4000}}}330.5342.5343.8364.1379.2376.5397.34200337.6348.5350.6369.2392.4389.7414.44400345.9353.7357.376.9402.1398.8426.84600352.2360.3361383.6410.9407.9440.94800354.3363.6365.9391.4419414.4453.54900357.8364.9366.2391.4419.9415.7456.7{{{5000}}}357.6365366.7390.9420.1414.44595100356.2366.2367.1388.7419.4413.1459.65200355364.1366.1386414.3409.3461.95400346.7356.5357.5377.3402.4397.8464.65600338346.3353371.3394.6390.3454.9 Dyno TorqueSuperflow DynorpmTest 1Test 2Test 3Test 4Test 5Test 6Test 72600442.2444.1454.8470.2455.7447.9443.62800449.7451.7462.5475.2463.2454.0456.03000456.8462.0472.2488.5474.0463.1473.43200463.3472.3480.3498.8486.8479.5495.03300463.5474.4481.6501.0492.7486.0501.63400461.0474.3481.7500.6496.0490.4{{{505}}}.53600456.6471.9476.2497.2501.6491.1517.33700452.0467.3472.1493.7502.8499.2519.63800446.9461.7466.4490.7501.3498.8523.04000434.0449.7451.4478.1497.9494.3521.74200422.1435.7438.5461.7490.7487.3518.24400412.9422.2426.1449.9480.0476.0509.54600402.1411.3412.2438.0469.2465.7503.44800387.7397.8400.4428.3458.5453.4496.25000375.7383.4385.2410.6441.3435.3482.25200358.5367.8369.7389.9418.4413.4466.55400337.2346.8347.7367.0391.4386.9451.95600317.0324.8331.0348.2370.1366.1426.6 Test DescriptionsTest 1:Stock 440 {{{Magnum}}}Test 2:Swap to Holley {{{850}}} CFM vacuum secondary carbTest 3:Swap to Extrude Honed exhaust manifoldsTest 4:Swap to Hooker 171/48-inch exhaust headersTest 5:Swap stock intake to Holley Street DominatorTest 6:Add 1-inch open plastic spacer under carbTest 7:Swap factory HP cam for Competition Cams' Xtreme Energy 274H;