To me, there were always two driveline components whose internal workings I've steered clear of-differentials and transmissions, their rebuilding, setup, and assembly have always been something of a mystery. Sure, I've always had a basic understanding of how they operate but I've, up to this point, always left these particular chores in the capable hands of professionals and never bothered to actually investigate what's really involved. Recently I had the opportunity to witness the step-by-step rebuilding of a GM 12-bolt rearend by one of SoCal's premier differential shops, Diff Works in Riverside, California, and the experience was an eye-opening one-one I'd like to share.

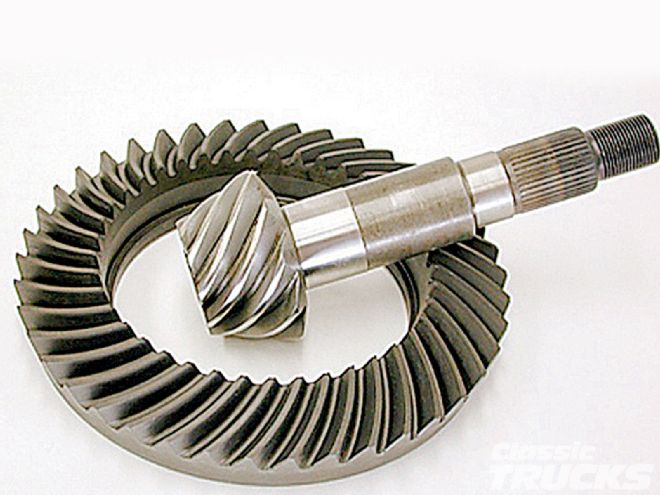

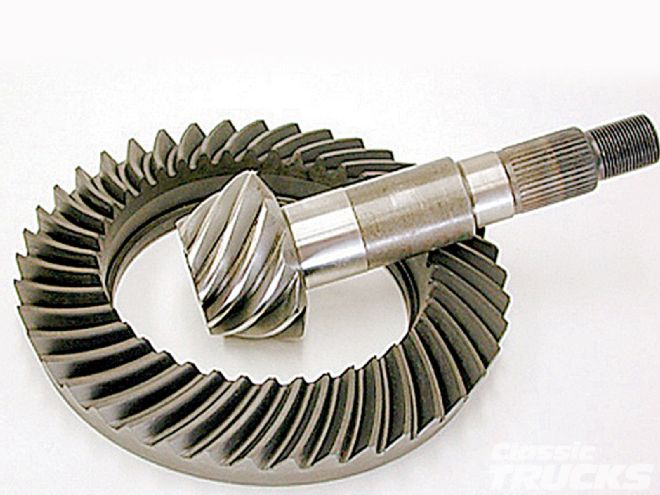

On the morning I stopped by the shop, Steve Post (Diff Work's resident expert and head cheese) was just getting ready to begin the assembly of a GM 12-bolt destined to be installed in a '55 Chevy pickup. He'd already prepped a suitable housing and was in the process of gathering the needed components for the first of many assemblies he'd complete that day. In this instance he'd be using customer-supplied components from Randy's Ring & Pinion, Yukon Gear, and Detroit Locker. I arrived just as he was beginning the assembly, and he kindly allowed me to watch over his shoulder (and took time to explain what he was doing) as he went about his business.

The following images and captions are the result of my visit, and I hope they serve to demystify the procedure as much for you as they did for me.