The single most important characteristic of a cylinder head is to move a large mass of air. The most important features of cylinder head design, which determine the mass of airflow delivered, are the shape and size of the runners, and the most effective shape is a straight shot down with a big valve opening. It comes as no surprise then that the almighty Chrysler Hemi is one of the most effective cylinder head designs when it comes to moving a boatload of air and fuel into an engine.

Crossbolted main caps are the quickest way to spot that this is no ordinary RB block, as only Hemi blocks used them. The aftermarket World Products cast block features actual Mopar insignia and a Mopar part number. Strengthening ribs on the sides of the block help keep these castings in one piece well north of the 1,000hp range. An aluminum block is offered for those wanting a “light” 600-plus cube engine.

Crossbolted main caps are the quickest way to spot that this is no ordinary RB block, as only Hemi blocks used them. The aftermarket World Products cast block features actual Mopar insignia and a Mopar part number. Strengthening ribs on the sides of the block help keep these castings in one piece well north of the 1,000hp range. An aluminum block is offered for those wanting a “light” 600-plus cube engine.

Corey Short has been a Mopar enthusiast since his pop, Bill, infected him with Hemi fever as a child. Now finally able to afford it, Corey continues to feed his illness by building Hemis for street and race cars alike. “I’ve been a die-hard Chrysler fan my whole life and growing up and reading these magazines, the Hemi was always the prize jewel for me.” Recently Corey, brother Troy, his pop Bill, and his mother Margie polished off this 514-cube Elephant blasting out over 800 horses for the 2011 AMSOIL Engine Masters Challenge under the team name “Triple S,” to represent the Short family. This was definitely not their first shot at the Engine Masters Challenge though. “We’ve been involved in the Engine Masters since 2004 and we’ve been kind of hooked ever since.”

Corey acted as team leader, but as mentioned above, his father has been a Pentastar patriot since the days of the early, baby Hemis. The first-generation Hemi burst on the automotive scene in late 1950 under the 1951 Fire Power name for Chrysler. Among Chrysler’s Fire Power, DeSoto’s Fire Dome, and Dodge’s Red Ram, the early Hemi blocks shared a deep-skirted Y-block design with their later cousins, but there were a number of subtle differences that kept parts interchangeability to a minimum.

A common modification for big-block Mopar racers is to use a reverse-cooling scheme. The water pump plate from Indy Cylinder Heads features internal passages that swap the flow around and cool the heads before the block. This lowers the combustion chamber temperatures in the head and reduces the chances of detonation. Plus, it allows the use of a cheap small-block Chevy water pump.

A common modification for big-block Mopar racers is to use a reverse-cooling scheme. The water pump plate from Indy Cylinder Heads features internal passages that swap the flow around and cool the heads before the block. This lowers the combustion chamber temperatures in the head and reduces the chances of detonation. Plus, it allows the use of a cheap small-block Chevy water pump.

The first major difference among the Hemi cousins was their different bore center distances, that is, the distance from one cylinder to the next. Though it may not sound overly important, it is the number-one most important factor in parts interchangeability. With different bore centers, head and cranks were automatically removed from any chance of swapping from one family to another. The Red Ram had the shortest bore-center distance of 4.1875 inches. Considering that there needs to be an absolute minimum distance between the cylinders of .200 inch for a head gasket of any type to seal, and typically about .400 inch for a regular composite gasket to seal with a safety factor acceptable to manufacturers, the bore size limitations of Dodge’s early Hemi become readily apparent. As a result, 241-, 270-, 315- and 325-cube entries were the limit for this baby engine.

DeSoto’s Fire Dome Hemi sported a slightly longer bore center dimension of 4.3125 inches. Displacement was a modest 276, 291, and 330 ci from 1952 to 1955, but the additional bore distance allowed a jump to 341 and 345 cubes in 1956 and 1957. Those last two years of the Fire Dome also saw the power output climb to the magical 1hp-per-cube range.

An MSD Blaster II coil provided ample spark for the Pro Billet distributor to fire. FireCore provided the spark plug wires that are unique to the Hemi. Unlike some cheapos, their sealed boots are about impossible to pull off. This is critical with Hemis as the plug wires need to come off every time the valve covers are pulled for valve adjustment.

An MSD Blaster II coil provided ample spark for the Pro Billet distributor to fire. FireCore provided the spark plug wires that are unique to the Hemi. Unlike some cheapos, their sealed boots are about impossible to pull off. This is critical with Hemis as the plug wires need to come off every time the valve covers are pulled for valve adjustment.

Chrysler opened the floodgates to bigger inch and bigger power potential with their 4.5625-inch bore center distance Fire Power Hemi. Compared to the old small-block Chevy’s 4.400 inches, the Fire Power Hemi had some room to grow. The first version emerged at 331 ci, but quickly grew to 354 inches by 1956, and in 1957 a raised-deck version bumped the size to an impressive 392 ci.

In 1958, the early Hemis fell by the wayside for nearly a decade until Chrysler committed to building an engine capable of winning in the growing NASCAR ranks. They pulled out all the stops and created the second-generation Hemi in late 1964, and it was available in street trim by 1966. The Gen II Hemi was a supersized version of its predecessors and was the basis of Corey’s engine. The Gen II shared a deep-skirted Y-block design of the early versions but added cross-bolted main caps and spread the bore centerlines to a healthy 4.800 inches.

The Shorts bypassed the use of a rare original block in favor of a new cast-iron block from World Products. The World Products aftermarket block uses the same big bore centerline of stock blocks but allows a maximum bore size of 4.600 inches, and a potential 632 ci with a possible 4.750-inch max stroke. Corey says, “The World Products block seems to have some advantages as far as oiling choices, and their finished product seems to be really clean right out of the crate.”

Old faithful. MSD celebrated its 40th year of ignition performance in 2010, and the 6AL has been installed in thousands upon thousands of cars proving its reliability. Building on that reliability, MSD recently unveiled their new Atomic EFI system, which has full self-leaning capabilities in a simple bolt-on system.

Old faithful. MSD celebrated its 40th year of ignition performance in 2010, and the 6AL has been installed in thousands upon thousands of cars proving its reliability. Building on that reliability, MSD recently unveiled their new Atomic EFI system, which has full self-leaning capabilities in a simple bolt-on system.

Typical Hemi block oiling systems use a screw-in ¾-inch tube to draw oil from the pan into a series of sharp right angles, to the oil pump and filter, then back to the block. World’s block has the option of either using the in-pan pickup like the factory, or at the front of the block near the pump is an extra inlet that can be used to draw oil from an external pickup line from the pan. “They put that in there so you have a little more options to get around K-members like on the B-Body and E-Body Chryslers. On that side you typically have a motor mount clearance issue among the pump and the mount and the header. It’s pretty tight. They made a setup where you can actually route an external pickup line coming in from the front. It helps out a lot of guys with cars like that.” This also comes in handy when using big stroke cranks that can’t clear a regular pickup. Another bonus to the Hemi is that the oil pressure can be externally regulated by just cranking in or out an adjusting screw on the back side of the external Melling M-Select oil pump.

Buried in the belly of the block is a 4340 forged steel crankshaft from Eagle Specialty products. Corey says he’s used the Eagle cranks in a number of combinations in the 800-plus horsepower range with nary a problem. Matching the big 4.15-inch arm is a set of Eagle’s H-beam connecting rods. Their lightweight but strong shape ensures that they won’t buckle under load or rip in half at the top end of a run. “The Eagle rods have got the 2000-series bolts in them, and they’re pretty much bulletproof for what we do in the naturally aspirated stuff. I don’t think you can hurt them.” To reduce bearing speed and friction, the rods and crank come straight from Eagle set up to run the smaller big-block Chevy-sized rod journals and bearings. That also helps with cost a bit as the more popular Chevy bearings run more than a few pesos cheaper than the true Mopar stuff. Another similarity with the Chevy is the .990-inch diameter wristpin. Factory Dodge pins come in at 1.094 inches and are typically quite a bit heavier. That’s great for blown alky engines, but just way overkill for anything under 1,000 hp.

The Pentastar Patriarch, Bill Short, readies the Triple S Hemi for dyno duty. Once the fluids are installed and WOT is verified, the timing is set. Most Hemis, like the Shorts’, require around 34-36 degrees of total timing for best performance.

The Pentastar Patriarch, Bill Short, readies the Triple S Hemi for dyno duty. Once the fluids are installed and WOT is verified, the timing is set. Most Hemis, like the Shorts’, require around 34-36 degrees of total timing for best performance.

The rod and main bearings that Corey chose to use were the same Speed-Pro parts anyone can buy from their catalog. Of course, choosing the right bearing for the application may not always be cut and dry. Speed-Pro offers four main categories of bearing material with four different material and shape combinations. Their aluminum bearings, designated the “AP” series, are a good choice for normal street applications due to their excellent fatigue resistance, conformability, corrosion resistance, and low cost. The Copper-Lead “CP” series uses a material referred to as H-24, and combines that copper and lead overlay on top of a steel backing to provide good fatigue resistance and strength in street and mild performance applications. The Super-Duty Alloy “CH” is Speed-Pro’s designated high-performance bearing material. The CH bearings have H-14 bearing material that is overlaid on top of a high-strength AK1020 steel backing for durability in high-load conditions. By high load, they mean big cylinder pressures and forces, such as those created in the Shorts’ Hemi. For the “other” Hemis running blown alcohol or nitromethane, Speed-Pro also offers a straight Babbit “SH” bearing. Those are built for maximum conformability and embedding under load, but not recommended for engines with any type of extended service life. In addition to the material difference between bearings, the high-performance bearings are also slightly more eccentric than truly round. By having a little more clearance toward the parting lines of the bearings allows them to not “pinch” the journals as the rod and main bores slightly deflect under high rpm load.

A Wilson tapered shear plate was added on top of the ported Indy intake manifold. Shear plates are usually seen on tunnel-rams but can be used successfully on single-plane intakes. They are designed to reduce the amount of reversion passing back through the carburetor and disrupting the fuel mixture.

A Wilson tapered shear plate was added on top of the ported Indy intake manifold. Shear plates are usually seen on tunnel-rams but can be used successfully on single-plane intakes. They are designed to reduce the amount of reversion passing back through the carburetor and disrupting the fuel mixture.

On the ends of those Eagle H-beams are a set of custom Wiseco forged pistons. “We used the Wiseco pistons this year and never had any trouble with any of their fitment at all and were really pleased with how things turned out with them,” Corey says. As the hemispherical combustion chamber naturally has a large volume, the pistons were designed with a mild dome in order to get the desired 11.4:1 compression ratio. That’s low enough to get by on pump gas but capable of bigger power on the good dinosaur sauce. Corey eschewed super-skinny piston rings in favor of a set of traditional 1/16-1/16-3/16 rings from Total Seal. He said that he prefers the stability of a 1/16-inch ring in applications that don’t have gas ports. “I’m not really convinced that helps out a lot of people. Ring sealing is critical, and that’s why I run a little bigger ring on it.” The torque required to rotate the engine seems to add credence to his claim. “The motor, without any valvetrain hooked up on it—basically just the short-block with those bigger rings—will spin over at just 28 ft-lb of torque with a torque wrench. There’s not a lot of friction there.”

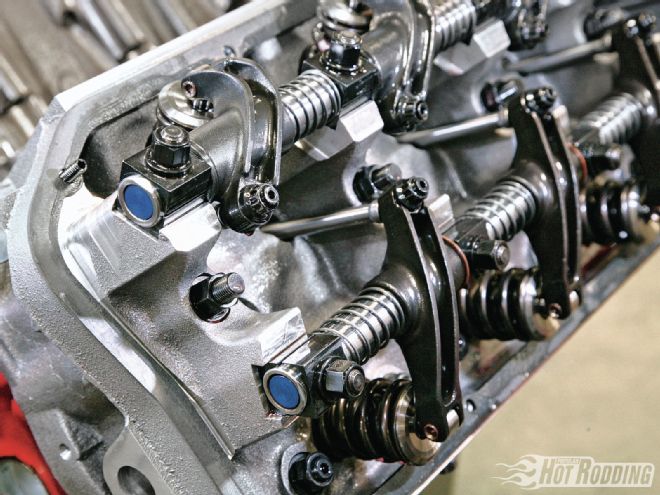

A thing of beauty for sure, but proper valvetrain geometry can be a headache on Hemi heads. The cast bosses on the Indy heads do allow for easy flat shimming of the rocker stands to correct any geometry issues caused by changing the valve lengths from stock.

A thing of beauty for sure, but proper valvetrain geometry can be a headache on Hemi heads. The cast bosses on the Indy heads do allow for easy flat shimming of the rocker stands to correct any geometry issues caused by changing the valve lengths from stock.

To finish off the rotating assembly, the Shorts installed an ATI Super Damper. The SFI-certified harmonic damper is the same quality level piece used by all of the top NASCAR and NHRA cars. On the other end, the eight-bolt crank flange is hooked to a Centerforce flywheel. When building similar combinations, it is important to note that typical wedge Chryslers use a six-bolt flange instead of the Hemi’s eight-bolt design.

Camshaft choice can be a tricky deal in itself, but when it comes to choosing a bumpstick for a Hemi, things get even tougher. Normal Wedge heads have the valves side by side, unlike the Hemi-style heads, which have the valves directly in line with each other. And the Hemis have a ton of exhaust flow compared to a Wedge head. That means the Hemi doesn’t need as much exhaust duration to get the job done. It also doesn’t need as much overlap for the exhaust scavenging pulse to help draw the fresh intake charge in. Quite often, as in Corey’s case, the cam will end up with the same duration on the intake and exhaust. By merely shortening the exhaust duration in relation to the intake, but keeping the intake centerline and the exhaust centerline in the same locations, there are two benefits. First, the exhaust valve will open later giving the burning fuel more time to push down on the piston. Second, closing that exhaust valve sooner decreases the amount of overlap and reduces wasted air and fuel going out the tailpipe.

The business end of this Hemi head sports a massive 170cc CNC-machined combustion chamber. An even dark tone verifies that the flame and fuel travel is even throughout the chamber with no washed-out spots. Unlike their Top Fuel cousins, dual spark plugs aren’t required here.

The business end of this Hemi head sports a massive 170cc CNC-machined combustion chamber. An even dark tone verifies that the flame and fuel travel is even throughout the chamber with no washed-out spots. Unlike their Top Fuel cousins, dual spark plugs aren’t required here.

In dyno testing different cams, Corey told PHR: “I’ve had them ground at 110- and 114-degree lobe separation, and 110 is going to give you a bigger peak torque number typically, but when the engine starts to fall off, it will fall faster than a 114-degree lobe separation cam. So if you’re going to be operating at 7,000 or 8,000 rpm, you’d definitely want to open that thing up, and I would be at least 114—and maybe 116 degrees—and flatten that curve out. It becomes like a tabletop at that point. But it typically won’t be as big of a peak torque number as if you were running something a little bit tighter.”

Corey worked with the experts at COMP Cams to build a solid-roller camshaft that would accomplish his goals of building good cylinder pressure without wasting effort and energy. They ended up with a grind that not only made killer peak horsepower but also had a big fat torque curve that would spin the Earth. The cam they installed was the second one they tested. “We set it in straight up and played with the lash adjustment a little bit just to find out what the motor was liking.”

Because the exhaust is so rolled over on the heads, the beefy Manton pushrods actually travel through holes that are machined in the block. This precludes bolting a set of Hemi heads on a “normal” non-Hemi big-block.

Because the exhaust is so rolled over on the heads, the beefy Manton pushrods actually travel through holes that are machined in the block. This precludes bolting a set of Hemi heads on a “normal” non-Hemi big-block.

None of that power would be possible, however, without the assistance of the monster CNC-ported heads from Indy Cylinder Head. Indy has been in the Hemi business for over 35 years and has amassed a volume of knowledge about the subject second only to Mopar itself. Corey says, “There really hasn’t been a whole lot of development on the Hemi for quite some time until Indy Cylinder Head got into the game.” The 514-cube engine in question needed a cylinder head that was capable of flowing a large mass of air in order to meet the targeted 800-plus horsepower, but was not going to be so large that low-rpm air velocity and torque would suffer from sluggish ports. The answer came in the form of Indy’s 426-1RA Legend heads. Corey’s “RA” heads have spacious 295cc runners. “They flowed about 483 on the intake and 330 on the exhaust at .700 lift. They have a raised exhaust, which certainly helps out on the flow. When I bought them, I had them retain the stock Hemi valve sizes, which were a 2.25 intake and a 1.94 exhaust, and I did that just to get a little more velocity out of them for more torque. It’s hard to get a Hemi to give you torque down low.”

Part of making big power with the Hemi head is by cranking those valves open as much as possible. “They like all the lift you can get. With an OEM head, you get too big and you start risking valve edges clipping each other. That 426-1RA head that Indy did actually starts playing with moving the valves around a little bit.” In fact, when designing the heads, Indy shifted the exhaust valve 2 degrees toward the cylinder wall in order to gain valve-to-valve clearance with tight lobe separation and/or big cam designs. They also have big honkin’ shaft rocker bosses cast directly into them. Those 1.6 ratio Indy rockers fit perfectly on the supports and operate Ferrea stainless steel valves without issue. “The good thing about it is when you put your rocker shafts on those pedestals, it’s really easy to shim those shafts in a position to correct the geometry, or travel misalignments across the valve tip.”

Unlike Wedge heads, the Hemi has dual rocker shafts and the design puts the exhaust valve so far to the opposite side of the head that significantly shorter exhaust valves are used. Another difference is that Hemi exhaust valves generally benefit from a tulip design instead of a flatter angle on the back side of the valve.

Unlike Wedge heads, the Hemi has dual rocker shafts and the design puts the exhaust valve so far to the opposite side of the head that significantly shorter exhaust valves are used. Another difference is that Hemi exhaust valves generally benefit from a tulip design instead of a flatter angle on the back side of the valve.

Another goody that the Indy heads have is a raised exhaust runner. Rather than having the hot exhaust gasses blowing out the valves then making a sharp U-turn to find headers mounted down low, the “RA” heads move the port exit up a solid .5 inch for a smoother transition to the header. When mocking the heads up in an actual car, it is recommended that the header-to-floorpan clearance be checked since it will be raised with those heads.

When asked for his advice on choosing a set of heads for a street Hemi, Corey told PHR: “The Hemi ports are big to begin with, and I would definitely pay particular attention to how big you go. I would be fairly conservative and stay a little bit closer to the smaller side, especially if you are going to be on the street with it. The [Indy] 426-1 heads will flow 430 at .700 lift and you compare that to an OEM head that flows about 330, so there’s quite a bit of difference.”

The block pushrod hole is seen between the upper head bolthole and the water passage. It is easy to see here how much dome is required on top of the piston to make an 11.4:1 compression ratio. High-compression (14-plus) engines would need a massive dome that almost mirrors the giant hemispherical combustion chamber in the head.

The block pushrod hole is seen between the upper head bolthole and the water passage. It is easy to see here how much dome is required on top of the piston to make an 11.4:1 compression ratio. High-compression (14-plus) engines would need a massive dome that almost mirrors the giant hemispherical combustion chamber in the head.

Because the Hemi heads are capable of moving such a large mass of air, it is quite common to see them with a big blower mounted on top. In the case of the Triple S Hemi, a naturally aspirated intake manifold was the solution. There are several options for intakes and the Shorts dyno tested three of them to find the best results. “The first time we ran it, I had an old Offenhauser tunnel-ram that had a single 4500-series carburetor on it, and it had a divider that almost split the whole plenum in half. The first time we pulled the trigger it started nosing over at 6,000 rpm abruptly, which was the first time I’ve seen any Hemi that I’ve built do that. So I had another intake manifold from Indy Cylinder Head, a 426-2, that I bolted on with a 4150-style 830 Holley, and it immediately picked up a full 100 hp over the tunnel-ram. Looking at the graph though, it was still nosing over pretty quick by about 6,800 rpm. Indy had another [426-4] manifold that was a little taller with a little more plenum volume and runner length that was set up for a 4500-series carburetor, so I tried that and it picked up another 60 hp,” Corey says.

During initial dyno tuning, the Shorts had an ignition problem to deal with on top of their intake trials. This was solved with the addition of a premium MSD dizzy that brought unexpected benefits. Corey says, “We had some issues with a distributor that I had in the engine, and so we bought an MSD Billet unit and tried it, and it liked that by 30 hp.”

When the Shorts got their engine dialed in, they were excited to get the whole family together and head to the University of Northwestern Ohio (UNOH) in Lima, Ohio, to see what the final results would show at the Challenge. “Some families like to get together and go on vacation. We get together and go dyno racing. That’s what we’ve been doing every year and we look forward to doing it some more,” he says. UNOH has hosted the AMSOIL Engine Masters Challenge for several years now and with the help of a number of enthusiastic student volunteers, the Triple S Hemi was strapped to the DTS/SuperFlow engine dyno. Flowmaster bullet-style mufflers were attached to the big elephant’s headers, and a set of Champion spark plugs lit off a fresh gulp of VP fuel, bringing the legend to life. Let it be said that there is nothing in the world that sounds as awesome as a real Hemi. And when that beast is abso-freakin-lutely screaming along at 7,500 rpm, it makes the hairs on your arms stand on end. When the dyno pulls were over and the little printer spit out the sheets, the proof was right in front of them that they had not only built an incredible 800hp monster, but they were some of the only people on the planet who had done it truly as a family affair.

The block pushrod hole is seen between the upper head bolthole and the water passage. It is easy to see here how much dome is required on top of the piston to make an 11.4:1 compression ratio. High-compression (14-plus) engines would need a massive dome that almost mirrors the giant hemispherical combustion chamber in the head.

The block pushrod hole is seen between the upper head bolthole and the water passage. It is easy to see here how much dome is required on top of the piston to make an 11.4:1 compression ratio. High-compression (14-plus) engines would need a massive dome that almost mirrors the giant hemispherical combustion chamber in the head.