For a number of reasons, making big power with pump gas has always been somewhat of a challenge. Issues such as detonation, reliability, and driveability all have to be considered and overcome to have a good all-around performer. Sonny's Racing Engines & Components in Lynchburg, Virginia, may have found just the right combination with its 762ci pump-gas monster.

"You've got to start with the best parts you can find," Founder Sonny Leonard says. "With a large displacement like we have here, it isn't that hard to make big power on pump gas. It is a little more difficult to build one that will last. With this engine, you'd be able to drop it in and drive coast to coast with good idle quality and enjoy it."

With Sonny's leadership, Sonny's Racing Engines & Components (SREC) has achieved a number of industry milestones. They were under the hood when Bill Kuhlmann drove the first doorslammer past the 200-mph mark 20 years ago. SREC developed the first 700 and 800ci GM-based engines, as well as a 5.000-inch bore center GM Hemi head. With this, SREC has 50-plus world records on land and water, along with a multitude of championships in categories such as Pro Stock, Pro Street, Outlaw 10.5, Comp Eliminator, and Power Boat racing.

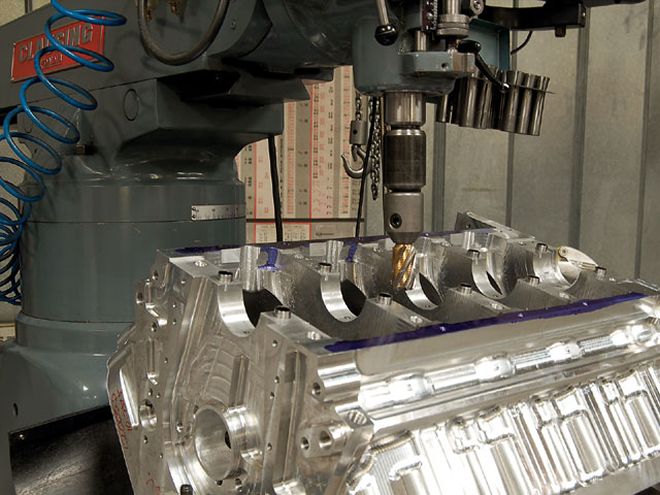

This block is being readied for milling so it can accommodate a larger stroke.

This block is being readied for milling so it can accommodate a larger stroke.

Bedrock Block

With SREC's reputation for monster power from mountain motors, one would expect this pump-gas engine to be part of the family. A full water, SREC/Donovan block was selected as the starting point for a number of reasons. With its tall deck, raised cam location, spread pan rails, and 5.000-inch bore center, this block allows use of a longer 5.375-inch stroke for more bottom-end torque at lower rpm, with a large 4.750-inch bore for greater volume.

A Sonny Bryant billet steel crank with Carillo steel rods anchors the bottom end on this combination. With the rods weighing in at 868 grams, that number added to the total reciprocating weight worked out to a total bob weight of 2,457 grams. An ATI 8-inch damper helps keep everything spinning smoothly.

On the opposite end is a set of dished Venolia 10.3:1 pistons with milled valve reliefs and shorter skirts to save weight. These are secured to the rod with a pin button. While the trend is toward lighter and thinner rings for reduced friction, SREC went with .047-inch top, .062-inch second, and .187-inch bottom rings for the sake of longevity. Since this is an aluminum block, all of the cylinder bores are sleeved in order to alleviate cylinder bore distortion.

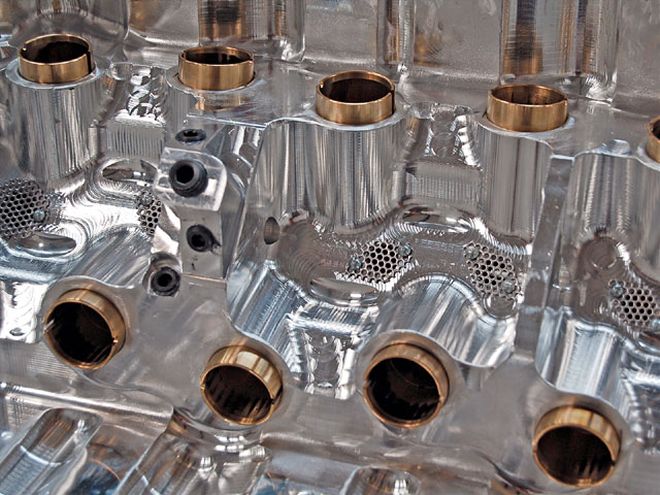

The valley of this SREC/Donovan billet aluminum block looks like a jewelry case.

The valley of this SREC/Donovan billet aluminum block looks like a jewelry case.

"When people ask how long an engine will last, you really have to answer that in terms of operating hours," Sonny said. "We recommend about 3,000 hours of run time under normal driving conditions before it should come in for freshening. The biggest thing that would need attention would be the lifters, springs, and rings. You can find cheaper ways to make power on pump gas, but it's a little harder to get away with it on a big, naturally aspirated engine. In the long run, that's why it pays to go with the best quality parts you can find."

Max Headroom

Of all the components in an engine, a cylinder head assembly is without a doubt the most complicated in terms of design. Assorted technologies such as compressible fluid flow, combustion, heat transfer, tribology, and mechanical dynamics, along with materials, manufacturing, and reliability engineering, all go into the final product.

While SREC's Next Generation GM Hemi heads represent the top of the food chain in terms of GM-based engines right now, SREC used a Pro-Stock-style, 5.000-inch bore center symmetrical wedge head on this pump-gas application. Intended just for applications of 500 ci or greater, these heads feature raised intake runners that have been redirected to the center of each cylinder for optimal fuel distribution.

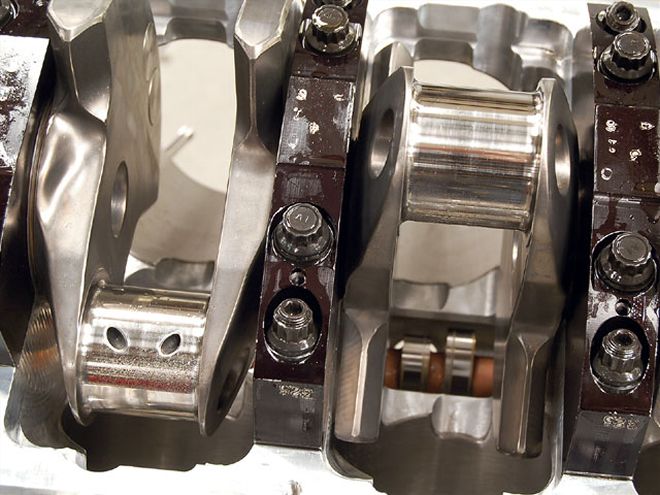

While OEMs will balance a crank to within +/-2 ounces, SREC uses a state-of-the-art Multi-Bal 5000 HMVF to bring that figure down to +/-2 grams to reduce parasitic horsepower losses, and improve the longevity of the bearings.

While OEMs will balance a crank to within +/-2 ounces, SREC uses a state-of-the-art Multi-Bal 5000 HMVF to bring that figure down to +/-2 grams to reduce parasitic horsepower losses, and improve the longevity of the bearings.

The volume of each runner worked out to 574 cc on the intake side, with 236 cc on the opposite end. At .900 inches of cam lift with 28 inches of water depression, these heads flowed 580 cfm on the intake and 407 cfm on the exhaust sides. The bore chamber was approximately 102 cc.

Designed with a 13-degree cant, SREC used a Manley 2.550-inch intake, and 1.930-inch exhaust valves. Both used a .3415-inch stem diameter. The valve seat was ground with 45-, 55-, and 65-degree angles for the intake, while the exhaust side used 45 and 55 degrees with a radiused angle.

T&D shaft-mounted, pressure-fed, 1.75:1 rocker arms are actuated by a SREC camshaft pushing Manton pushrods. Counterbalancing the camshaft is a set of Manley NexTek double valvesprings with a 1.640-inch OD and .860-inch ID, which exert 280 lbs of seat pressure at installed height, and 604 lbs open pressure. These are used with 10-degree titanium retainers and a 1.740-inch OD spring cup. Tapered ARP head studs measuring a half inch in the block, and 7/16-inch on the head end were used with Clark gaskets for optimal sealing.

Components such as connecting rods are carefully weighed, along with pistons, rings, and bearings, to get an exact bob weight prior to mounting the crank on the electronic balancer.

Components such as connecting rods are carefully weighed, along with pistons, rings, and bearings, to get an exact bob weight prior to mounting the crank on the electronic balancer.

Induction

SREC offers a number of different top-end options for this engine: naturally aspirated, EFI, or a Roots-style blower. The latter would require a change in pistons and camshaft. Turbocharging, while possible, would only be feasible if twins were used. Even so, it would probably be better suited to a smaller displacement.

The 762 pump-gas engine photographed for this article used a 4x2 sheetmetal intake manifold that was fabricated in-house at SREC. To optimize torque, SREC used long runners, which are aimed squarely at each cylinder for optimalfuel distribution.

"With our background in Pro Stock, we've seen a lot of experimentation in plenum sizes, runner lengths, and widths over the years," Sonny says. "We do all of our intake manifolds in-house in order to keep that information proprietary to us. We make these intakes available to the public when they're sold as an induction kit with the cylinder heads."

This view during assembly shows the machining done for clearance.

This view during assembly shows the machining done for clearance.

Bo Laws Performance provided four two-barrel carburetors that were separated and offset in order to provide a shot as straight as possible down each intake runner. This is done not only to improve the metering signal, but to maintain an equal air/fuel ratio between each of the cylinders.

Special features in the main bodies include idle transfer slots that go into the body at the same angle as the throttle blades. Each of the metering plates were machined from 6061 aluminum so that there are no issues whatsoever with casting porosity. On this particular application, the carburetor's venturi size was 1.730 inches, while the throttle bore was 2.000 inches.

Tale Of The Tape

With everything assembled, warmed-up, and ready, the hills around Lynchburg howled while the 762 pushed out peak readings of 1,153 hp at 6,300 rpm and 1,085 lb-ft of torque at 5,100 rpm. These tests were done on a SuperFlow SF-902 using 93-octane pump gas.

"People are a lot more knowledgeable now than they were some years ago," Sonny said when asked about the availability of these engines. "So, we've decided to make this engine package available in kit form so engine builders, racers, and other enthusiasts can save money by assembling it themselves."

With a broad torque band and an abundance of flywheel horsepower, this combination proves to be an attractive package for both the pump-gas racer and street/strip machine.

DYNO RESULTS RPM TQ HP 4,400 1,039.9 871.2 4,500 1,041.7 892.5 4,{{{600}}} 1,049.1 918.8 4,700 1,065.4 953.4 4,800 1,071.3 979.1 4,{{{900}}} 1,081.3 1,008.9 5,000 1,084.7 1,032.6 5,{{{100}}} 1,085.0 1,053.6 5,{{{200}}} 1,081.3 1,070.6 5,{{{300}}} 1,075.5 1,085.4 5,400 1,068.8 1,098.9 5,500 1,061.6 1,111.7 5,600 1,051.2 1,120.9 5,700 1,045.0 1,134.1 5,800 1,032.7 1,140.4 5,900 1,021.9 1,148.0 6,000 1,007.0 1,150.4 6,100 992.2 1,152.4 6,200 975.3 1,151.4 6,300 961.2 1,153.0 6,400 945.9 1,152.7 6,500 {{{928}}}.5 1,149.2 6,600 910.1 1,143,7 6,700 893.8 1,140.2 ENGINE SPECIFICATIONS Block: SREC/Donovan aluminum 5.000-inch bore center Bore: 4.750 inches Stroke: 5.375 inches Displacement: 762 ci Compression ratio: 10.3:1 Crankshaft: Sonny Bryant, 5.375-inch stroke Rods: Carillo, 7.536-inch billet steel Main journal: 2.748 inches Main bearing clearance: .0036 to .0042 inch Rod journal: 1.1985 inch Rod bearing clearance: .003 inch Bearings: Clevite, H-series Piston: Venolia, dished 10.3:1 Top ring: .047 inch Top ring gap: .015 inch Second ring: .062 inch Second ring gap: .035 inch Oil ring: .187 inch Cylinder heads: SREC Pro Stock, symmetrical wedge Intake valve: Manley, 2.55-inch titanium Exhaust valve: Manley, 1.930-inch Inconel Camshaft: SREC/LSM solid roller Cam duration: 262/276 degrees at .050 Valve lift: .831 inch Rocker ratio: 1.75:1 Lobe separation: 116 degrees Intake manifold: SREC, custom 4x2 sheetmetal Carburetor: four BLP two-barrel (588 cfm each) Ignition: MSD