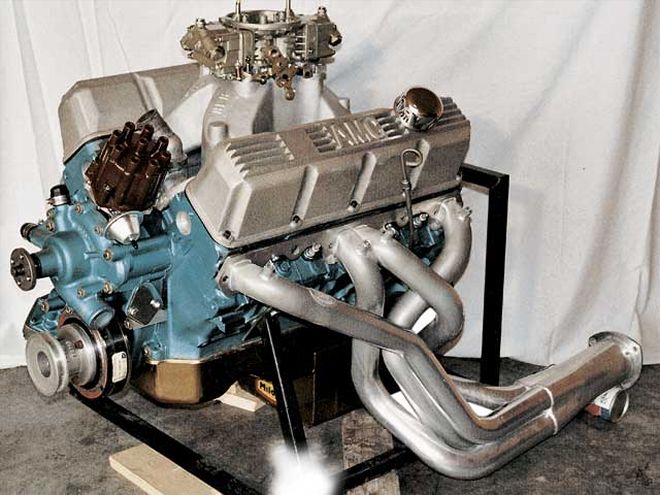

Want sick power from a basically stock engine? Try a 401. Using factoryheads on the portly 4.170-inch bore, you can build torque where itcounts and still make good power on top with a reasonable cam, goodvacuum, and off-the-shelf parts. In the case of the buildup we'reoutlining here, the payoff was 484 hp at a streetable 5,600 rpm andnearly 500 lb-ft of torque at 4,600, with more than 450 lb-ft from 2,500to the horsepower peak.

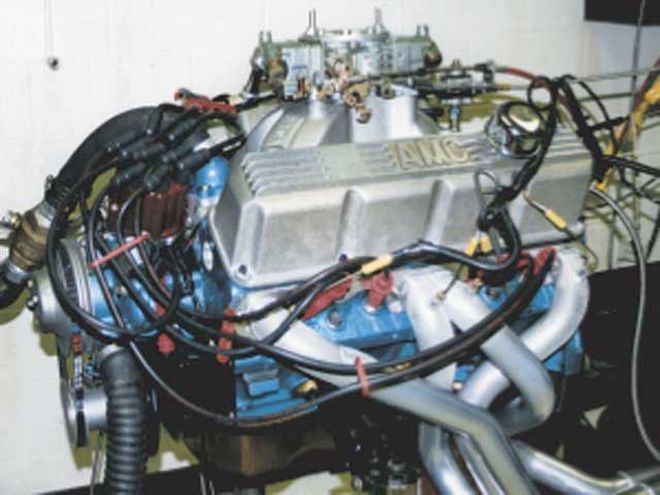

With the help of JT Payton at Payton's Performance, Holley MarketingManager Bill Tichner did all of that. His goal for the 401 was to use asmany stock parts as possible and create as much power as possible whilestill maintaining at least 13 inches of vacuum for an aftermarket fuelinjection system to come later. The performance key to this engine isheavy port work on the iron heads, attention to the oiling system, and acouple of other tricks we will outline in this story. This engine'sdestiny is to be stabbed into an AMX, and with a little shot of spray,lift the wheels at its favorite track.

The Block

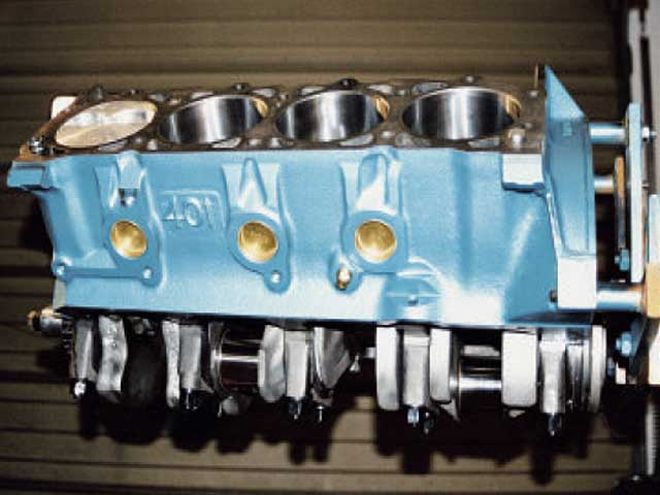

The practical limit of the plebian AMC 401 is about 500 hp at 7,500 rpm.The main caps will begin to walk above that, so limit these engines tohealthy street mills if you want to keep the price down and use stockparts. Just because we're interested in this kind of thing, we foundthat with an available four-bolt main kit, you can go to 700 hp and9,500 rpm for the full-race Chihuahua. Whee. But this is a streetengine, so Tichner used a post-'70, tall-deck block bored 0.030-over for4.195 inches and used the stock two-bolt main caps with big-block Chevystuds from ARP.

We'd recommend using the stock bore if you can. Payton's says the highnickel content in these blocks makes them resistant to wear, and0.030-over is on the limit of the 401's block design. So if you don'thave to bore, hone it and move on.

The Rotating Assembly

Lots of goodness here. The stock rods and crank on all AMC 390 and 401engines are forged from the factory. To keep them working, Payton'sshot-peened the stock 5.85-inch rods to relieve stress and used apressed piston pin for street durability and low bucks. For full-tiltmills, Payton's uses a 6-inch Chevy rod and turns the rod-bearingjournal down to 2.100 inches from the stock 2.248 for reducedcylinder-wall loads and 7,500-plus-rpm capability. Taking no chances,they use ARP rod bolts as well.

The 401 crank has a 3.68-inch stroke and is more than manly enough withjust a polishing of the journals and chamfering of the oil holes tolive. It's worth mentioning that the '72-and-later 401 crank had aTorqueFlite 727 flange, so look for the casting number 812-0510 or youwill have to modify the flange to get it to work with a modernautomatic.

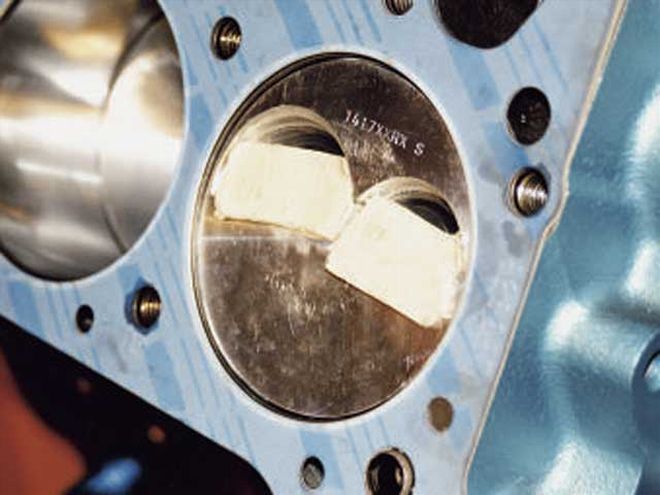

We asked a couple of builders about off-the-shelf pistons and got headscratching and thinking but no part numbers. This engine uses a customLunati aluminum-alloy forged flat-top for future use of race gas andnitrous. At around $640, it is the most glaring expense on this engine.The slugs have a 1.48-inch compression height with two 17-degree valveeyebrows spaced 1.590 inches apart with a total of 11.23 cc's of relief.With a 0.043-inch thick gasket, 0.020-inch deck clearance, and the 64ccheads they're good for 10.0:1 compression.

Cylinder Heads

There are Indy and Edelbrock heads available for the AMC, but Tichnerwanted to use the stock dog-leg heads. The cork in their design is theintake runner and the exhaust-port-to-header match. Payton's put inabout 11 hours of work to cut the stock valve seats and fit a set of2.08 intake and 1.625 exhaust valves and raise the intake runner.Payton's machinists are careful to avoid the intake floor, because pastexperiments found that changes there actually hurt airflow. Extensivework in the combustion chamber was performed to unshroud the valves andopen the chamber from 58 to 64 cc's. This was also helpful in reducingthe compression on this engine to run on pump gas. The final flownumbers were 279/210 cfm at 0.700-inch lift at 28 inches of water. Thoseare big ports for a cast-iron street head.

On the exhaust side, the rough casting was cleaned up and the headerswere port matched to the heads. Early Super Comp 17/8-inch full-lengthheaders for the '68-'74 Javelin/AMX and '74 Matador need to have theflange opened up a bit to match the exhaust port, but new headers ofthis design should already be modified to fit.

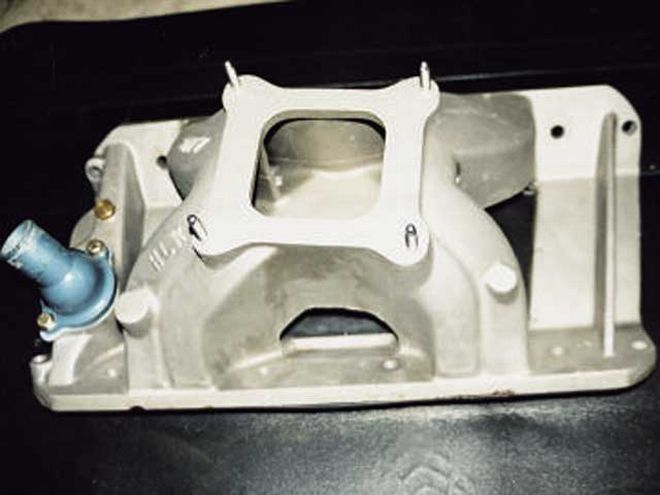

Carb And Ignition

This engine was built with the future installation of Holley's Commander950 MPFI kit in mind. It has a single-plane manifold and throttle-bodyincluded. For the dyno run, Tichner used a manifold that is similar indesign from Herman Lewis Racing and a 950-cfm Holley HP Seriesmechanical-secondary carb. The cfm might seem a little much, but thisengine is going into a light AMX that will likely see more WOT on thetrack with a plate of nitrous than street cruising. According toPayton's dyno sheet, the A/F ratios were correct for this size carb onthis combination.

MSD offers both a standalone ready-to-run distributor and the Pro-Billetthat requires an MSD 6-, 7-, 8- or 10-series ignition to operate. Bothcome with a vacuum advance and replace the stock points stuff. Tichnerchose the Pro-Billet and a set of Autolite AR52 racing plugs to spark itall.

Cam and Valvetrain

The cam was a sacrifice to get some vacuum at a loaded idle. It is aLunati hydraulic flat-tappet grind with 230/235 degrees of duration at0.050, a valve lift of 0.0523/0.0540, and 108 degrees of lobeseparation. The full-kill cam is also a Lunati grind, but it uses asolid lifter and has 249/259 degrees at 0.050 and 0.579/0.598 lift withthe same lobe separation angle. It will sacrifice more idle quality andvacuum but would likely crest 500 hp on this combination. The rockerarms are aluminum rollers made for a Ford 260-351W but useable on the090 and 993 castings with Lunati springs with 105 pounds of seatpressure at 1.80-inch installed height.

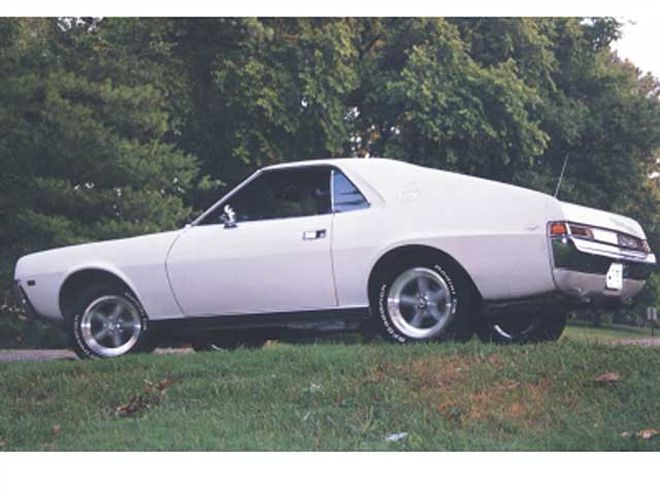

The AMX

Ultimately, the engine is destined for Tichner's AMX. We'll let him tellits story.

The main oil-galley boss needs to be tapped at the front of the liftervalley using an AN-6 and a 1/4-inch NPT or AN-8 with a 3/8-inch NTP andrun to the rear of the valley.

The main oil-galley boss needs to be tapped at the front of the liftervalley using an AN-6 and a 1/4-inch NPT or AN-8 with a 3/8-inch NTP andrun to the rear of the valley.

"I bought the car from JT (Payton) when I was 17 and drove it dailythrough five years of college. Then I joined Holley in 1994 and drove itfor a year until I was able to afford a more dependable car (with A/C,fuel injection, and better gas mileage). I have been driving the caras-is as a toy since marriage, a home, and kids took all my income. Nowafter 10 years at Holley I am able to really start working on it. Thebodywork has just been finished and the engine compartment is painted.It is going to be Pepper Grey Metallic with black Go Pack stripes. OnceI put everything back in the engine compartment, it's going back forpaint. I have a TorqueFlite 727 that I got with the 401 out of the donor'73 International Travel-all, but I am not sure if I will build it orsomething else at this point. I still need to build the rearend tohandle the power as well. I know I want 3:55 gears and probably a 2,500stall since the torque comes on immediately from this motor. The car wasoriginally a 390-cid car. I bought it with a 290 and then put ahigh-compression 360 in it during college. Now it has the 401. I amgoing with the multipoint EFI so the factory hood will be able to close.You can't get this kind of power out of an AMC and keep it under thestock hood with a carb."

Tips and Tricks

It's no secret that the AMC V-8 has a failing in its lubrication system.Oil from the pickup travels through a passage on the oil-pan rail into apump with an aluminum housing that tends to wear, then to the filter,and finally to the main oil galley. It's nowhere near good enough foreven a stocker, in our opinion. The solution is the Milodon single ordual pickup that bolts directly (and conveniently) to a Milodondeep-sump oil pan. It bypasses the stock restriction and nearly doublesoil flow to the filter and mains. Payton's adds a filter before the oilreaches the pump gear in conjunction with a direct-oil feed from themain galley in the lifter valley to the rear main bearings, because on astock AMC, they're the last in line and tend to fail during high-rpmuse.

Stock AMC oil-filter adapters are made of aluminum, and the pump-gearface rides directly on the housing and wears it down. Fortunately SpeedPro sells a replacement kit for the oil-pump gear assembly and pressurespring, and we've seen the 340/360 Mopar service replacement housingbeing used for 390/401 performance applications, so look to Jeeps forthis part.