From the lowest class of stock car racing all the way up to the NASCAR Winston Cup Series, wiring is an important aspect of getting your race car to Victory Lane. One bad connection or exposed wire can ruin your chances of finishing the race. Circle Track spoke to numerous experts who deal with wiring systems in race cars to come up with some hot tips on how to install and maintain your race car's wiring system.

Many of our experts manufacture and install wiring systems for the upper levels of auto racing, such as the Winston Cup Series. Though their products may be at the higher end of the racing spectrum, their tips on proper wiring cover all classes of racing.

In regards to weatherproofing and fire prevention, Dennis Overholser of Painless Performance supplied us with a great many tips, while Wade Brown of Brown & Miller Racing Solutions gave us some pointers on connectors, terminals and switches. Last, but not least, David Hatfield of Hatfield Ignition let us in on some of his tips for batteries, battery cables and ignition wires.

Dennis Overholser is co-founder and vice president of new product development and technical services of Painless Performance in Fort Worth, Texas. He has been in the automotive/racing industry since the mid to late '60s and acquired his electronics training in both the military and at DeVry. Painless Performance supplies parts for all aspects of circle track racing.

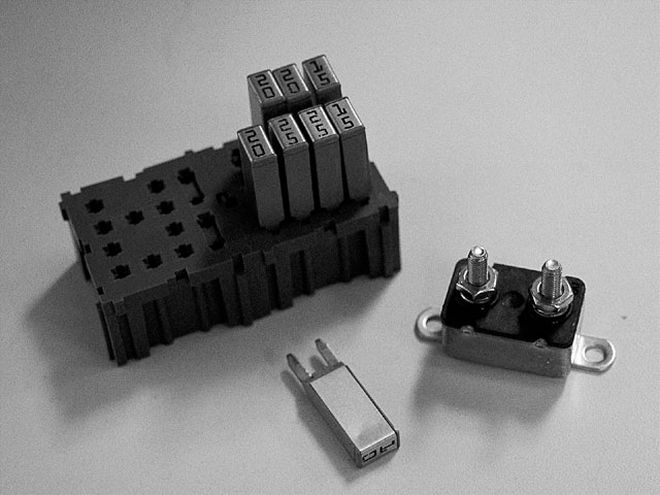

To avoid overheating it is essential you use fuses or circuit breakers on all electrical circuits.

To avoid overheating it is essential you use fuses or circuit breakers on all electrical circuits.

For the Saturday-night racer, weatherproofing is essential due to washing the mud and dirt off and out of the race car after the races.

1. Electrical connections can easily be protected with heat-shrinkable connectors, which in some cases have glue inside the terminal that when heated to shrink will also form a watertight seal. These are standard crimp connectors that shrink and seal with the use of a heat gun or small flame.

2. If a fuse center is in need of protection, a simple plastic bag held in place with a rubber band will provide reasonable protection against water and dirt.

3. Inline fuses can also be protected with waterproof fuse holders. An electrical fire is usually caused by equipment failure or wiring that has shorted to ground. There are several simple things that can be done to help prevent an accident.

4. Keep wires away from moving objects, such as brake and clutch pedals.

5. Use fuses or circuit breakers on all electrical circuits to avoid excess overheating. It is better to burn a fuse than the car.

6. Use only high-temp wire, and keep it away from exhaust manifolds and headers.

7. Ensure the battery is properly secured.

Terminals come in all shapes and sizes. Choosing the correct terminal for your car's wiring system, along with a proper crimp, will ensure a reliable connection and, in most cases, a night free of electrical problems.

Terminals come in all shapes and sizes. Choosing the correct terminal for your car's wiring system, along with a proper crimp, will ensure a reliable connection and, in most cases, a night free of electrical problems.

8. Route wires through rubber grommets in bulkheads.

9. Install ground straps between the engine and the body and frame. Don't allow your throttle cable to become a body ground.

10. Always route wires on the rollcage and body where they are visible to the driver. Never route wires between the cage and the body where they may be pinched in a collision.

Vibration is one thing that can destroy an electrical system in no time. Electrical connections left hanging loose will soon come apart. Using the glue-type terminals and attaching the wiring to the rollbar or body with simple plastic wire ties will aid in the connection not coming apart. Loose wires will also chafe and short if left to vibrate against rough edges.

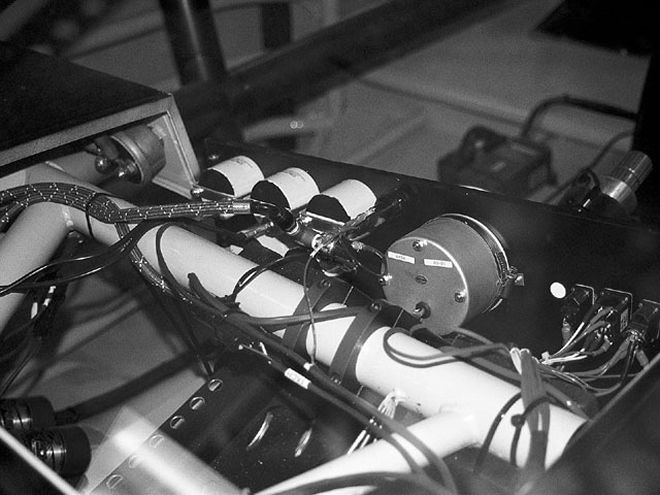

Wade Brown and David J. Lee of Brown & Miller Racing Solutions in Concord, N.C. supply wiring systems to Evernham Motorsports, along with other Winston Cup, Busch Grand National and Craftsman Truck Series teams. The wiring division of Brown & Miller Racing Solutions was established in 1999. BMRS personnel possess a combined 32 years of production and high-performance automobile wiring experience and an additional 12 years of electronic engineering experience. BMRS specializes mainly in custom-engineered and -built stock car harnesses using only the latest in assembly equipment.

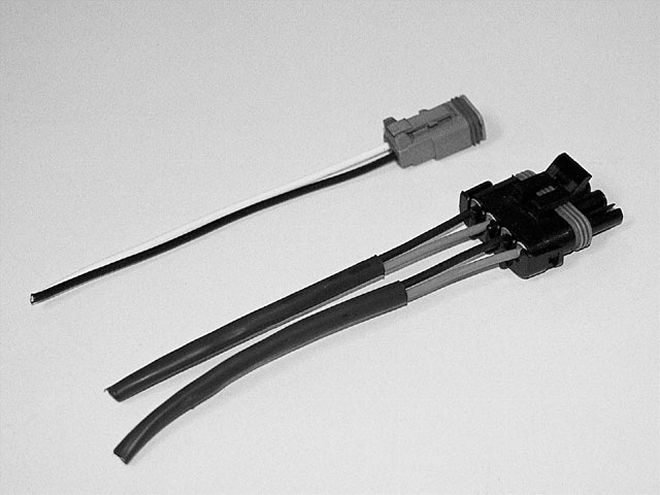

Careful selection of connectors is important. Environment, type of connector and current rating, among other things, should all be considered in order to prevent electrical failure.

Careful selection of connectors is important. Environment, type of connector and current rating, among other things, should all be considered in order to prevent electrical failure.

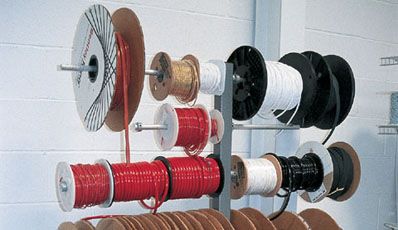

1. Wire type and size should be chosen based upon load requirements, temperature and operating environment. Be sure the wire size you are using is not too small for the load size. A variety of insulation types are available for varying temperature and environmental conditions.

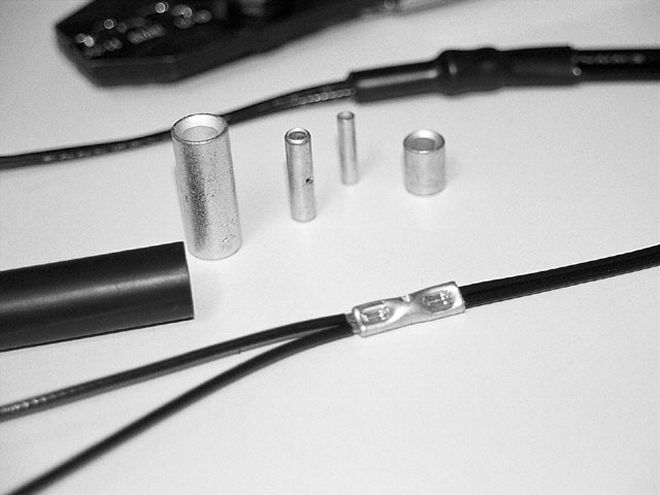

2. Terminals (i.e. ring, spade etc.) are not only sized by hole or opening size, but also by wire size. A correctly sized terminal/wire combination, when crimped properly, will result in a very reliable connection.

3. Be careful in selecting your connectors. First, consider the environment where the connector is used. A sealed connector is typically best to keep dirt and moisture from contaminating the contacts. Second, a latching-type of connector will prevent the connector from vibrating apart. Third, be sure you do not exceed the current ratings for each contact in the connector. Fourth, make certain each contact is fully seated in the cavity. Many racing electrical failures are due to contacts simply not inserted completely in the connector housing.

4. While splicing, in most cases, is not desirable, it is usually necessary. A splice barrel is most commonly used and, like terminals, it is important to select a barrel based upon the wire size you are using.

Like terminals and connectors, it is important to select the correct barrel size when you are splicing wire. Select your barrel size based on the wire size you are using.

Like terminals and connectors, it is important to select the correct barrel size when you are splicing wire. Select your barrel size based on the wire size you are using.

5. Be sure the switch you are using is adequate for the load size. Many devices used on race cars (i.e. fans and blowers) can easily exceed the current rating for a switch. Also, be sure to use a "rugged" switch that can withstand the high-vibration environment in a race car.

6. A relay should be used when the current you are switching exceeds the rating of the switch you are using.

7. Using the proper crimp tool for the contact you are using will result in a reliable crimp. There are a wide variety of tools available for most types of contacts. Wrong tool selection may result in:

* Under-crimped loose connections

* Over-crimping causing broken wire strands

* Distorted and unreliable crimps

8. There are many opposing views on the use of solder on a wire harness. When applied properly, soldering can create a very high-quality connection and actually compensate for a poor crimp. Too much soldering will result in overheating the wire and "wicking" of solder under the insulation. The wire will then become very brittle and may be prone to breaking.

9. Be sure to put extra effort and time in the routing and installation of the wire harness. Avoid areas susceptible to damage, high temperatures or areas where excessive flexing occurs.

10. A good ground connection is absolutely essential. A loose or broken ground connection will result in your entire electrical system failing. A reliable wire harness will begin with a secure and robust ground connection.

David Hatfield has 23 years of experience in racing. He is currently the shop foreman for Herzog Motorsports' No. 92 NASCAR Busch Grand National Series Monte Carlo. On the side, Hatfield, a licensed electrical contractor, is the owner of Hatfield Ignitions, which specializes in custom wiring harnesses and ignition wire sets. His systems have won in the NASCAR Winston Cup, Busch Grand National and Craftsman Truck Series.

Proper crimp tool selection is almost as important as the wiring system itself. Poor crimps may cause unreliable connections and broken wire strands. Crimping tools range from the more expensive powered crimpers to the basic manual crimper most racers should have in their tool box.

Proper crimp tool selection is almost as important as the wiring system itself. Poor crimps may cause unreliable connections and broken wire strands. Crimping tools range from the more expensive powered crimpers to the basic manual crimper most racers should have in their tool box.

1. Most local divisions do not run alternators; therefore you must run a battery that can withstand high ampacity quick charges. I have found the most popular battery is a stud-type top mount.

2. A No. 4 size tin-coated copper battery cable is more than sufficient for most racing applications. Be sure insulation is free of any type of defect and terminal ends are clean and tight.

A shroud, whether it is made of nylon or another type of material, is often recommended for added protection of the wiring harness assembly.

A shroud, whether it is made of nylon or another type of material, is often recommended for added protection of the wiring harness assembly.

3. Wire is not a place to compromise on quality. I recommend using silver-coated, copper-stranded, Teflon-insulated wire. It is lightweight and in many cases can carry twice the ampacity of a similar automotive-type wire.

4. I recommend using a nylon shroud for the harness assembly. This shroud rates at a high temperature.

5. As for terminals, I find nickel-plated steel terminals, which are crimped and soldered, to be the best.

6. Quality comes first when thinking of your ignition wires. I believe that an eight-millimeter spiral core should be a minimum requirement.

7. The shorter your wires are, the better. This makes everything lighter and simplifies the installation, maintenance and troubleshooting.

A: Quick-Fix Recipe

Even if you follow all of these tips to the letter, you can still have problems. And most likely those problems will occur at the track. That is just how racing works.

"For quick track fixes, your best friends would be a test light, a crimping tool and a small selection of terminals," says Matt Goss of Pacific Industrial Components Inc. (Pico) Wiring Accessories, also the driver of a 200-plus mile-per-hour blown alcohol funny car. "You could probably do just about anything with those. Maybe throw in a piece of wire. You can always splice it if you need to get the car up and rolling again. Also a roll of black electrical tape is essential for quick fixes."

Proper assembly and installation are extremely important when it comes to your car's wiring system. Extra time and effort should be put into routing the assembly. You want to avoid sharp edges, areas susceptible to damage, high temperatures and anywhere that flexing may occur.

Proper assembly and installation are extremely important when it comes to your car's wiring system. Extra time and effort should be put into routing the assembly. You want to avoid sharp edges, areas susceptible to damage, high temperatures and anywhere that flexing may occur.

Keep these inexpensive items in your trailer toolbox, and you don't have to worry about not finishing a race because you don't have the essential items to fix a simple wiring problem. Goss also recommends you keep everything clean and make sure you don't have any wires or terminals coming apart. "Basic visual maintenance is very important," he cautioned.

wiring accessories to make your installations easier

Courtesy of Pico Wiring Accessories1. Battery accessories

2. Booster cables

3. Clips and clamps

4. Connectors

5. Fasteners

6. O-rings and grommets

7. Heat shrink tubing

8. Switches

9. Tie wraps

10. Tools

11. Wire

12. Wire covering