The snowball is rolling, and poised to bury you in an avalanche of debt. But fear not, for exercising a few wise decisions and plotting out your battle plan in advance is all it takes to prevent your budget-built project car from mutating into an oxymoron. As our foray into the promised land of single-digit e.t.'s continues to progress, it came time to plumb up a fuel system for Project Fox's 532. Peering out in misery from between the shock towers like Robert Downey Jr. gazing out the window of a Malibu rehab facility, the 775hp big-block was begging for a hit of some tasty 93-octane brewski. Although feeding a motor with such a voracious appetite can get quite costly, we managed to pull off the feat for $804, thanks to a dollar-stretching turnkey fuel system from Russell Performance.

While budget-priced high-performance hardware is certainly part of the equation, we could have easily spent four times as much money on a fuel system had we stuck with EFI on our '93 Mustang. The 52 lb/hr injectors necessary to fuel nearly 800 hp would have gobbled up two-thirds of our entire $804 budget. Furthermore, the stand-alone engine management system, wiring harness, mondo throttle body, and custom intake manifold mods necessary to run EFI could easily ring up another $3,000. Since plans call for running at either idle or wide-open throttle-and not much in between-who gives a hoot about the driveability advantages of EFI? The comprehensive Russell fuel system (PN 641523) includes a monster 160-gph electric pump, 20 feet of -8AN hose, an inline filter, hose clamps, all necessary fittings and wiring, a pressure regulator, and a fuel pressure gauge.

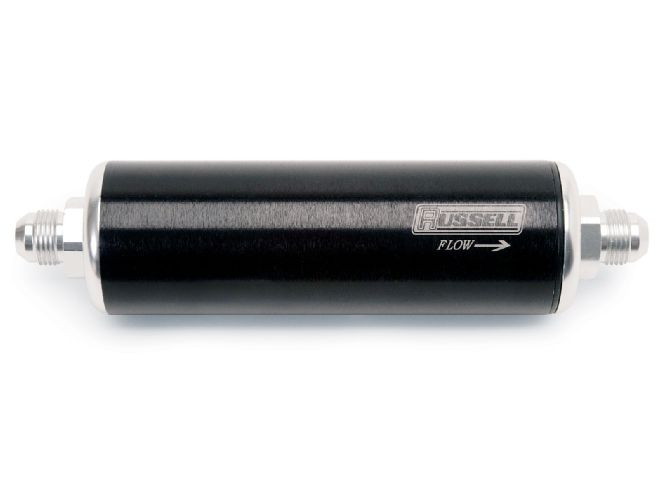

Fuel filters must be carefully matched to the pump, as any restriction they impose will reduce pump performance. Russell's 8.25- inch inline filter is more than up to the task. It features an anodized aluminum housing, and a replaceable 60-micron nylon filter element.

Fuel filters must be carefully matched to the pump, as any restriction they impose will reduce pump performance. Russell's 8.25- inch inline filter is more than up to the task. It features an anodized aluminum housing, and a replaceable 60-micron nylon filter element.

Keeping things simple and cheap has been the underlying theme of Project Fox since the beginning, and we decided to skip on the mini-tubs while the chassis was under construction. Larger wheel tubs usually require installing either a narrower gas tank or mounting a fuel cell in the trunk, neither of which are appealing in a dual-role street/strip car. Fortunately, with the luxury of being able to retain the stock fuel tank, there's still plenty of room in the trunk to stash fat bags of cash hustled off unassuming victims on cruise night. Or so we've heard.

The Edelbrock pressure regulator included with the Russell kit is adjustable from 5-10 psi by turning the adjustment screw located at the top of the unit. In addition to a gauge port, the regulator has two outlet ports, making it compatible with both single- and dual-feed-style carburetor logs.

The Edelbrock pressure regulator included with the Russell kit is adjustable from 5-10 psi by turning the adjustment screw located at the top of the unit. In addition to a gauge port, the regulator has two outlet ports, making it compatible with both single- and dual-feed-style carburetor logs.

At the risk of sounding obsessive-compulsive, we have to give a huge thanks to the folks at Bill Buck Race Cars once again for pulling an all-nighter this time around. With Project Fox now plumbed up, all it needs is a cooling system, exhaust, and an interior rehab before it's ready for action.

How Much Pump?

Determining how large of a fuel pump a motor requires is contingent upon power output, brake specific fuel consumption, and target fuel pressure. The BSFC of most naturally aspirated motors ranges from .400-.500 lb/hr (per horsepower), while forced induction applications vary from .600-.650 lb/hr. We know from prior dyno testing that Project Fox's 532 big-block burns between .400- and .450 lb/hr of fuel while cranking out 775 hp. Furthermore, like most carbureted motors, it operates at 6-7 psi of line pressure. Using this info, all it takes is some simple math to calculate the fuel volume necessary to feed this thirsty mill. Since motors are far less forgiving of lean air/fuel mixtures than rich mixtures, it's good practice to add a safety margin of 10 percent to the BSFC figure. Thus, multiplying our big-block's 775 hp by a conservative BSFC of .500 yields a fuel volume requirement of 387.5 lb/hr of fuel.

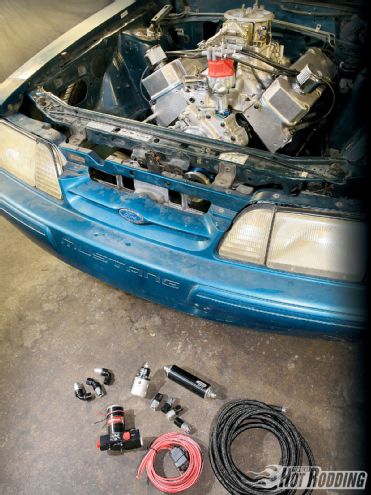

Russell's comprehensive fuel system includes every nut, bolt, clamp, fitting, and wire necessary to route fuel from the tank to the carburetor. No impromptu trips to the hardware store! The system is offered with either a 120-gph pump that supports up to 480 hp for $615 (PN 641593), or with a 160-gph pump that's good for over 1,000 hp for $740 (PN 641523).

Russell's comprehensive fuel system includes every nut, bolt, clamp, fitting, and wire necessary to route fuel from the tank to the carburetor. No impromptu trips to the hardware store! The system is offered with either a 120-gph pump that supports up to 480 hp for $615 (PN 641593), or with a 160-gph pump that's good for over 1,000 hp for $740 (PN 641523).

Like most fuel pumps on the market, the advertised 160-gph rating of the Edelbrock pump included in our Russell kit represents its performance under free-flow conditions. That rating drops to 80 gph at 6.5 psi. Nonetheless, it still flows more than enough fuel for our application. Since gasoline weighs roughly 6 pounds per gallon, the Edelbrock pump's 80 gph rating equates to 480 lb/hr of flow. Even with our safety factor of 10 percent, this beast of a pump flows 20 percent more fuel than our big-block demands. In fact, the pump's output can feed 960 naturally aspirated horsepower, even while assuming a super-conservative BSFC of .500 lb/hr. Using a more realistic BSFC figure of .450 lb/hr, the Edelbrock pump is good for 1,066 hp.

Return Lines

As with most carbureted fuel systems, we opted to run a deadhead-style pressure regulator and forego the return line option. Although return lines are most often associated with EFI, there is a time and place to run them, even in a low-psi carbureted application. In extreme situations, the constant recycling of fuel from the tank, to the motor, and back to the tank decreases the potential for overheating the fuel. Return-style systems also respond more quickly to changing fuel demands, which means that the carb's fuel bowls will stay full a greater percentage of the time. Nevertheless, many of the biggest and baddest carbureted motors around run just fine without a return line. For the sake of keeping things simple and cheap, Project Fox will make do with a more common deadhead-style system. Should the need arise, however, converting to a return-style fuel system is as easy as swapping in a bypass regulator, and plumbing a return line from it to the tank.

The Edelbrock pump included in the Russell kit isn't just impressive for its flow rate, but also for its lack of size. Compared to other pumps on the market that move a similar volume of fuel, it's roughly 33 percent smaller. The slick black anodized housing conceals composite rotors and carbon-fiber vanes that provide greater durability, and reduced friction and wear. Edelbrock says its pumps are 4 to 14 decibels quieter than comparable units.

The Edelbrock pump included in the Russell kit isn't just impressive for its flow rate, but also for its lack of size. Compared to other pumps on the market that move a similar volume of fuel, it's roughly 33 percent smaller. The slick black anodized housing conceals composite rotors and carbon-fiber vanes that provide greater durability, and reduced friction and wear. Edelbrock says its pumps are 4 to 14 decibels quieter than comparable units.

Line Sizing

Different brands of fuel hoses have different flow rates, as two hoses with identical outside diameters don't necessarily have the same inside diameter. Consequently, it's difficult to generalize how large of a fuel line a given application requires based on horsepower alone. After selecting a fuel pump that provides adequate flow for an engine's needs, it's simply a matter of matching up the size of the fuel supply line with the same size fittings a manufacturer supplies with the pump. That's because pump manufacturers conduct exhaustive testing to determine the proper inlet and outlet sizes that work best with the flow characteristics of their pumps. According to Russell, using a feed line larger than the size of the pump outlet won't necessarily improve flow. High-pressure EFI motors can get away with running a feed line that's one size (1/8-inch) smaller than the pump outlet, but when factoring in the negligible cost savings in doing so, it make no sense at all.

The 20 feet of -8AN hose supplied with the Russell system is more than enough to reach from the tank to the carb. It's offered in both stainless and nylon-braided hose that's rated at 350 psi of pressure. This extremely durable and abrasion-resistant hose is also compatible with oil and coolant.

The 20 feet of -8AN hose supplied with the Russell system is more than enough to reach from the tank to the carb. It's offered in both stainless and nylon-braided hose that's rated at 350 psi of pressure. This extremely durable and abrasion-resistant hose is also compatible with oil and coolant.

This same rule of thumb applies to the fuel supply line (from the tank to pump inlet) as well, but with one exception. The only time when it might be beneficial to run a slightly larger supply line is when the pump inlet has an NPT port. In such a scenario, Russell suggests using a supply line that's one size larger than the port inlet. For instance, if a fuel pump has a 3/8-inch NPT inlet port, it's advisable to run a 1/2-inch (-8AN) supply line.

WHERE THE MONEY WENT Item: PN: Price: Russell fuel system 641523 $740 Comp Engineering fuel sump C4041 $64 Total: $804

THE COST SO FAR Description: PHR Issue: Price: '93 notchback Mustang November 2009 $3,000 Sold old wheels, tires, engine, trans N/A -$1,000 532 big-block Ford June 2009 $9,644 Phoenix Turbo 400 trans September 2009 $1,645 Strange 8.8 rearend October 2009 $1,759 Comp Engineering rear suspension November 2009 $1,708 AJE front suspension December 2009 $1,679 Bill Buck custom 10-point cage January 2010 $2,000 Engine and trans install March 2010 $690 Russell fuel system April 2010 $804 Total: $21,929